Flame-retardant engineering plastics and preparation method thereof

A technology of engineering plastics and hyperbranched polymers, which is applied in the field of flame-retardant engineering plastics and its preparation, and can solve the problems of easy decomposition, popularization and application, easy combustion of engineering plastics, and unfavorable molding processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of flame-retardant engineering plastics, the specific steps are as follows:

[0047] (1) Preparation of metal modified hyperbranched polymer;

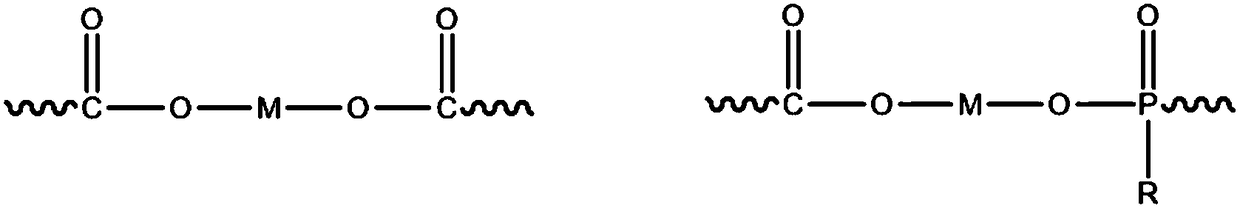

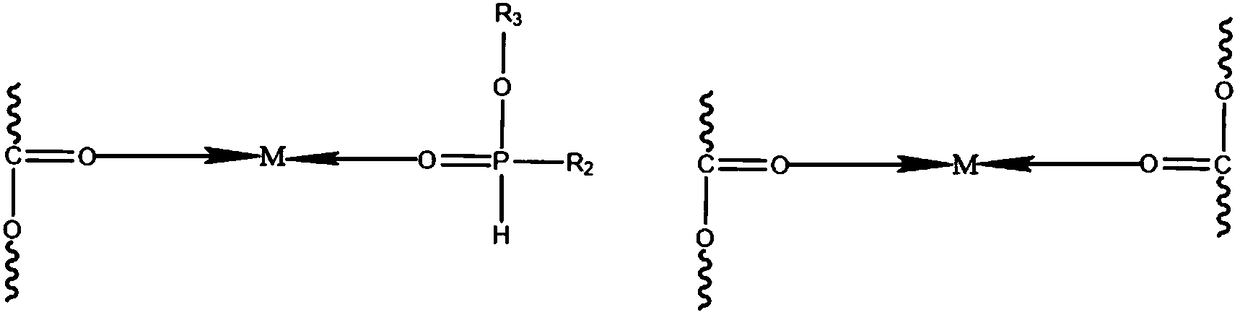

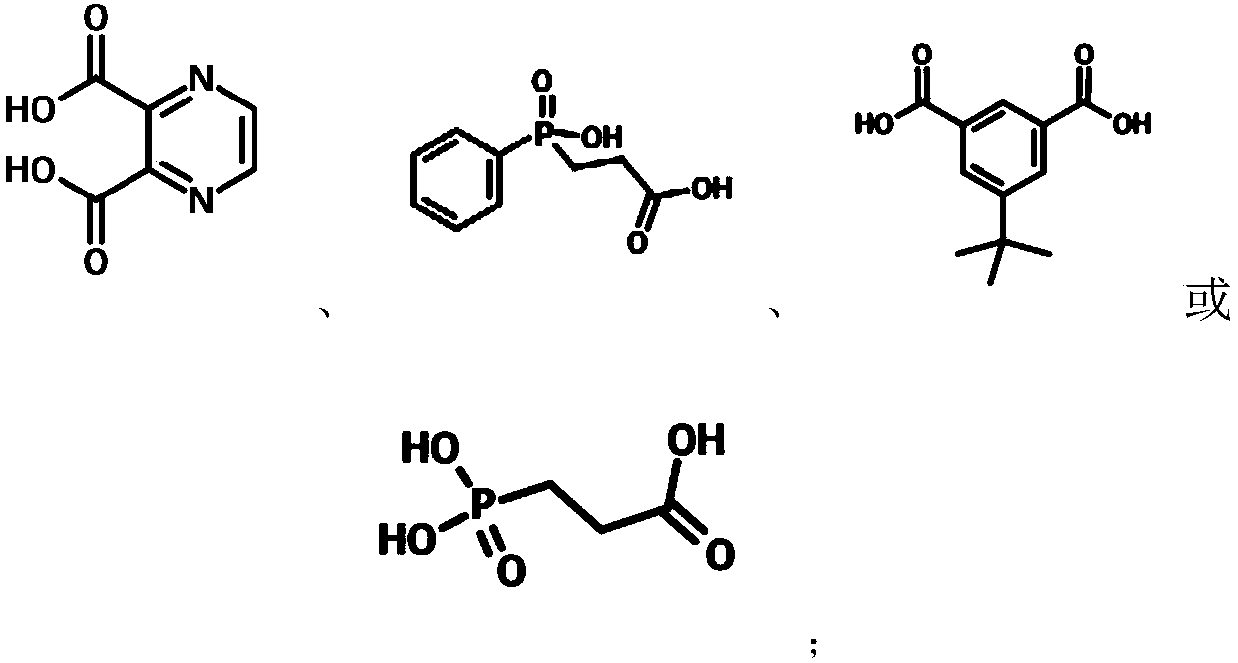

[0048] (1.1) Use A 2 +B 3 Synthetic method to prepare a hyperbranched polymer with terminal carboxyl group: A 2 Is pyrazine-2,3-dicarboxylic acid; B 3 1,1,1-tris(hydroxymethyl)propane;

[0049] The prepared hyperbranched polymer with end groups containing carboxyl groups contains ester groups in its molecules, the number of carboxyl groups accounts for 25% of the total end groups, the degree of branching is 60%, and the weight average molecular weight is 2000 g / mol;

[0050] (1.2) Dissolve the hyperbranched polymer with carboxyl end groups in chloroform to obtain a concentration of 0.7 mol / L of the hyperbranched polymer solution with carboxyl end groups, and dissolve cobalt acetate in deionized water to obtain a concentration of 0.8 mol / L. L metal ion solution;

[0051] (1.3) Under the conditions of mechanical stir...

Embodiment 2

[0058] The preparation method of flame-retardant engineering plastics, the specific steps are as follows:

[0059] (1) Preparation of metal modified hyperbranched polymer;

[0060] (1.1) Use A 2 +B 3 Synthetic method to prepare a hyperbranched polymer with terminal carboxyl group: A 2 Is: 2-carboxyethylphenylphosphinic acid; B 3 Is: Tris (2-carboxyethyl) isocyanurate;

[0061] The prepared hyperbranched polymer with end groups containing carboxyl groups contains ester groups in its molecules, the number of carboxyl groups accounts for 27% of the total end groups, the degree of branching is 53%, and the weight average molecular weight is 43,000 g / mol;

[0062] (1.2) Dissolve the hyperbranched polymer with carboxyl group at the end group in acetone to obtain a solution of the hyperbranched polymer with carboxyl group at the end group concentration of 0.85mol / L, and dissolve nickel acetate in deionized water to obtain a concentration of 0.95mol / L. L metal ion solution;

[0063] (1.3) Unde...

Embodiment 3

[0070] The preparation method of flame-retardant engineering plastics, the specific steps are as follows:

[0071] (1) Preparation of metal modified hyperbranched polymer;

[0072] (1.1) Use A 2 +B 3 Synthetic method to prepare a hyperbranched polymer with terminal carboxyl group: A 2 As: 5-tert-butyl-1,3-benzenedicarboxylic acid; B 3 As: 2,4,5-trihydroxyphenylbutanone;

[0073] The prepared hyperbranched polymer with end groups containing carboxyl groups contains ester groups in the molecule, the number of carboxyl groups accounts for 25% of the total end groups, the degree of branching is 30%, and the weight average molecular weight is 15000g / mol;

[0074] (1.2) Dissolve the hyperbranched polymer with carboxyl end group in N,N-dimethylformamide to obtain a solution of the hyperbranched polymer with carboxyl end group at a concentration of 0.9 mol / L. Obtain a metal ion solution with a concentration of 1.0 mol / L in ionized water;

[0075] (1.3) Under the conditions of magnetic stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com