A kind of using method of preparing hydrogen fluoride circulating fluidized bed rectification device

A circulating fluidized bed, hydrogen fluoride technology, applied in hydrogen fluoride, fluorine/hydrogen fluoride, chemical instruments and methods, etc., can solve the problems of high gas film mass transfer coefficient, non-corrosion resistance of column internals, short liquid residence time, etc. Achieve the effect of large liquid film mass transfer coefficient, improved thermodynamic efficiency, and small liquid back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

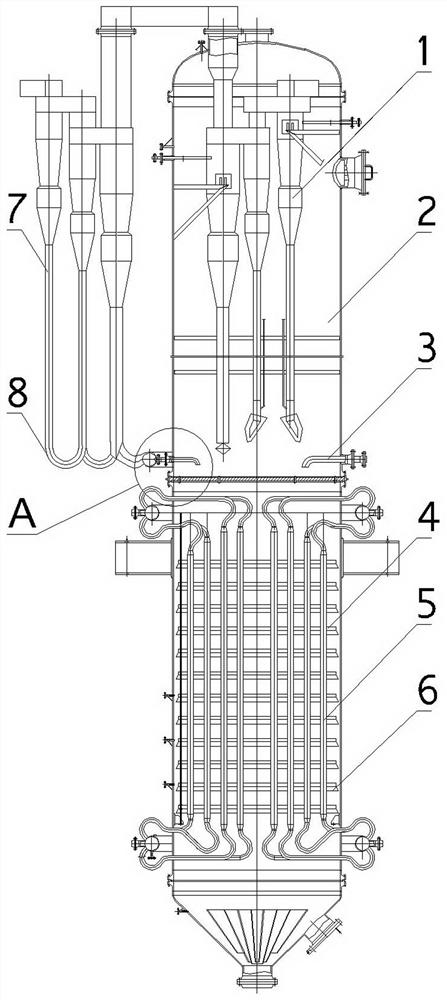

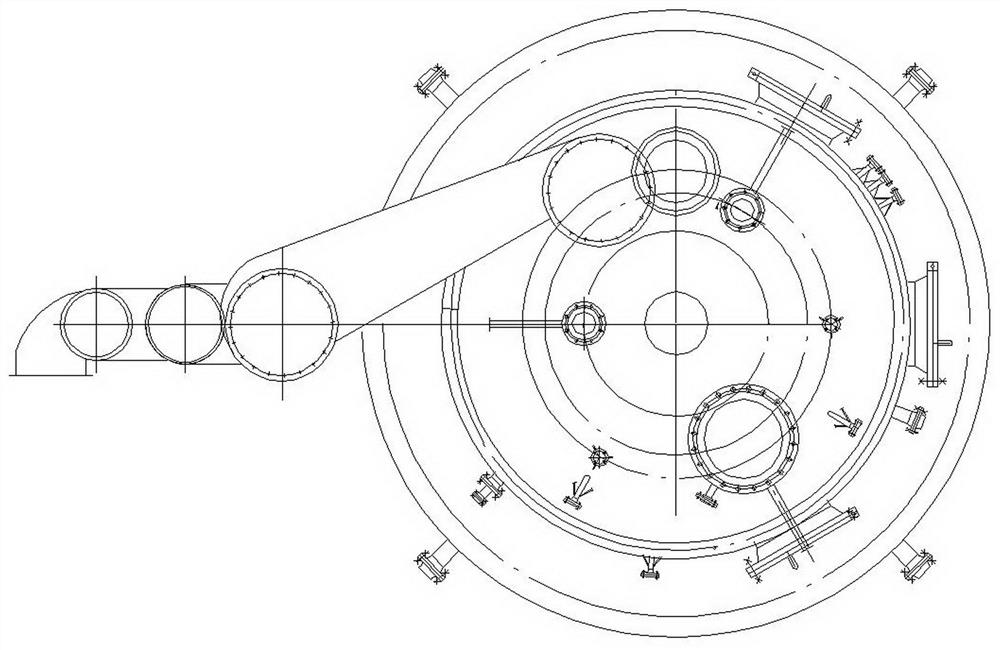

[0020] Such as figure 1 , figure 2 , image 3 As shown, a method of preparing a fluoride circulating fluidized bed rectification device is characterized by:

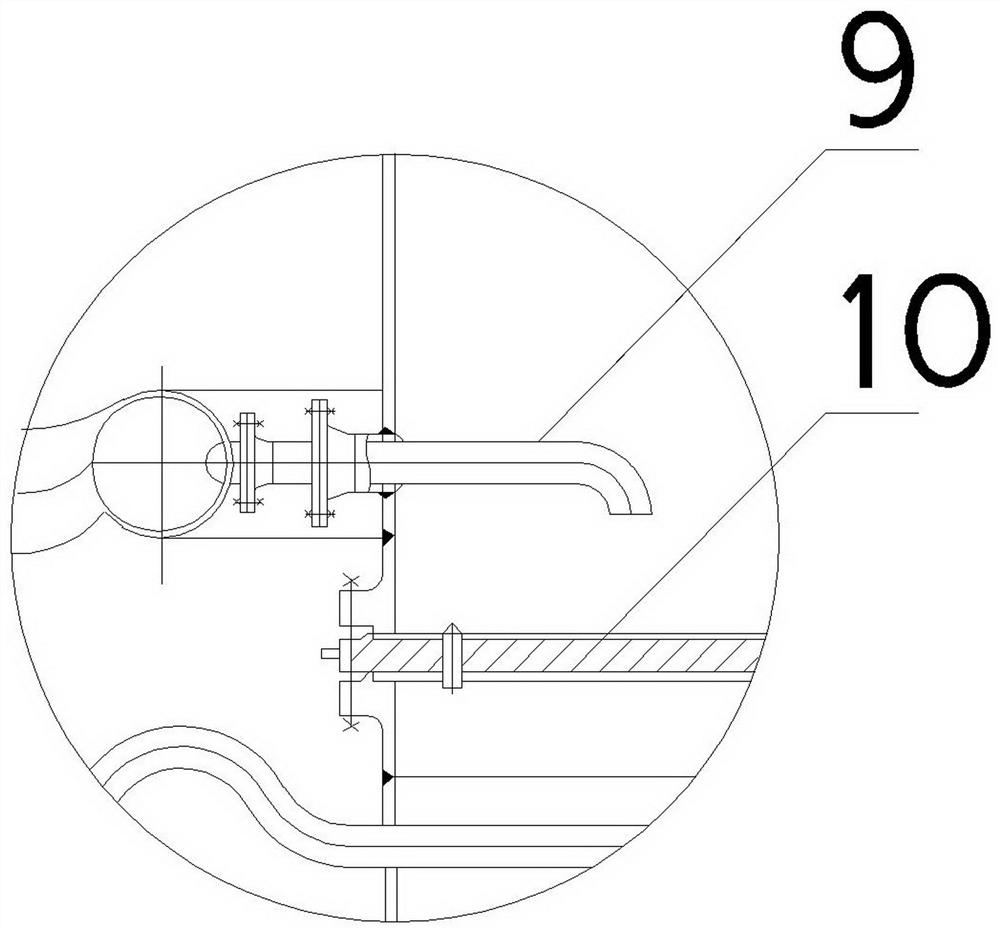

[0021] Step 1, must observe the liquid level of the multi-stage cyclone condenser II7 bottom U-type liquid seal 8 before use, ensuring that the liquid level is higher than the return tube 9 at least 300 mm, ensuring that the U-type liquid seal 8 is in a normal operating state. .

[0022] Step 2, the crude hydrofluoric acid solution is supplied from the material liquid conduit 3 designed in the middle of the circulating fluidized bed distillation tower body 2, injecting the liquid disc 10, injection temperature 9 ° C, crude hydrofluoro acid liquid to subjected to liquid disc 10 uniformly distributed The rear drops of the reboiler 4, the reboiler 4 includes a heat transfer tube 5 and a fin plate 6, and the reboiler 4 heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com