Solidago canadensis L. straw biochar, preparation method and application thereof in removing LAS of detergent waste water

A biochar and yellow flower technology, applied in chemical instruments and methods, water pollutants, and other chemical processes, can solve problems such as environmental pollution, large investment in equipment, secondary pollution, etc., and achieve simple environmental protection process, low preparation cost, The effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

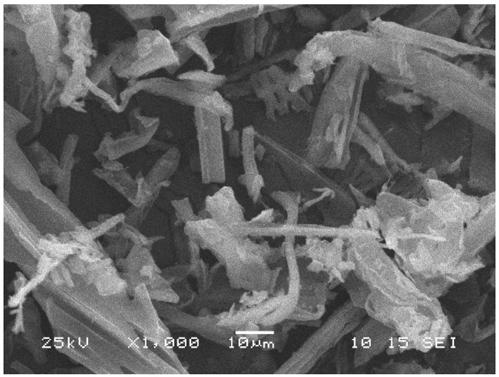

[0037] The branches and leaves of the collected mid-to-late Solidago canadensis were removed, and only the stalks were kept, washed with tap water, dried in an oven at 65°C for 12 hours, and then crushed through a 100-mesh sieve to obtain Solidago canadensis stem powder. The obtained Solidago canadensis stalk powder was placed in a muffle furnace, kept at 100°C for 1 hour, and then heated to 400°C at a rate of 10°C / min for carbonization for 2 hours. After cooling in the muffle furnace, take it out, soak it in 0.1mol / L HCl solution for 6 hours, filter it, wash it with distilled water until it is neutral, then filter it and dry it to constant weight, grind it through a 100-mesh sieve, and pack it into a bag for later use. Yellow flower stalk biochar. The SEM image of the prepared biochar is shown in figure 1 , see the Fourier transform infrared spectrum Figure 5 , from the SEM image of biochar, it can be seen that Solidago canadensis has rich pore structure inside after carbo...

Embodiment 2

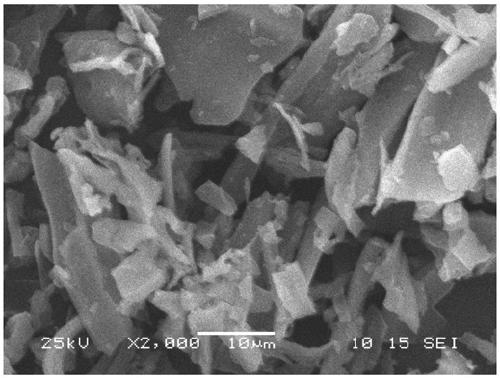

[0039] The branches and leaves of the collected Solidago canadensis were removed, and only the stalk was kept, washed with tap water, dried in an oven at 65°C for 12 hours, and then crushed through a 100-mesh sieve to obtain the solidago canadensis stem powder. The obtained Solidago canadensis stalk powder was kept at 100°C for 1 hour in a muffle furnace, and then heated to 500°C at a rate of 10°C / min for carbonization for 2 hours. After cooling in the muffle furnace, take it out, soak it in 0.1mol / L HCl solution for 6 hours, filter it, wash it with distilled water until neutral, then filter it and dry it to constant weight, grind it through a 100-mesh sieve, and pack it into a bag for later use to obtain a Canadian branch Yellow flower stalk biochar. The SEM image of the prepared biochar is shown in figure 2 , see the Fourier transform infrared spectrum Figure 5 ,From figure 2It can be seen that there are many chaotic fragments inside the biochar at 500 °C and the pore ...

Embodiment 3

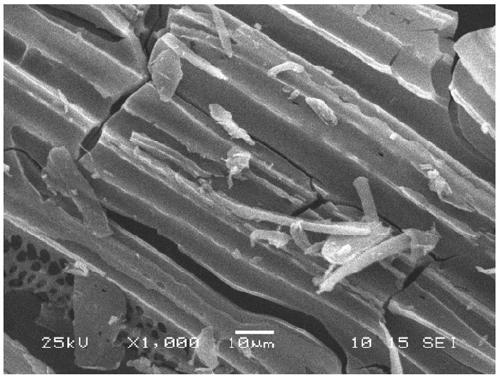

[0041] The branches and leaves of the collected Solidago canadensis were removed, and only the stalk was kept, washed with tap water, dried in an oven at 65°C for 12 hours, and then crushed through a 100-mesh sieve to obtain the solidago canadensis stem powder. Then keep the obtained Solidago canadensis stalk powder in the muffle furnace at a temperature of 100°C for 1h, then raise the temperature to 600°C for 2h at a heating rate of 10°C / min, and take it out at 0.1mol / min after cooling in the muffle furnace. Soak in L of HCl solution for 6 hours, filter, wash with distilled water until neutral, filter and dry to constant weight, grind through a 100-mesh sieve and pack into bags for later use to obtain solidago stalk biochar. The SEM image of the prepared biochar is shown in image 3 , see the Fourier transform infrared spectrum Figure 5 ,Depend on image 3 It can be clearly seen that the surface of biochar has a relatively regular microporous structure and the fragments on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com