Printing material for ceramic core, preparation method of printing material and preparation method of ceramic core

A technology for ceramic cores and printing materials, applied in cores, casting molding equipment, casting molds, etc., can solve the problem of high requirements for printing materials, and achieve the effects of good surface quality, good fluidity, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

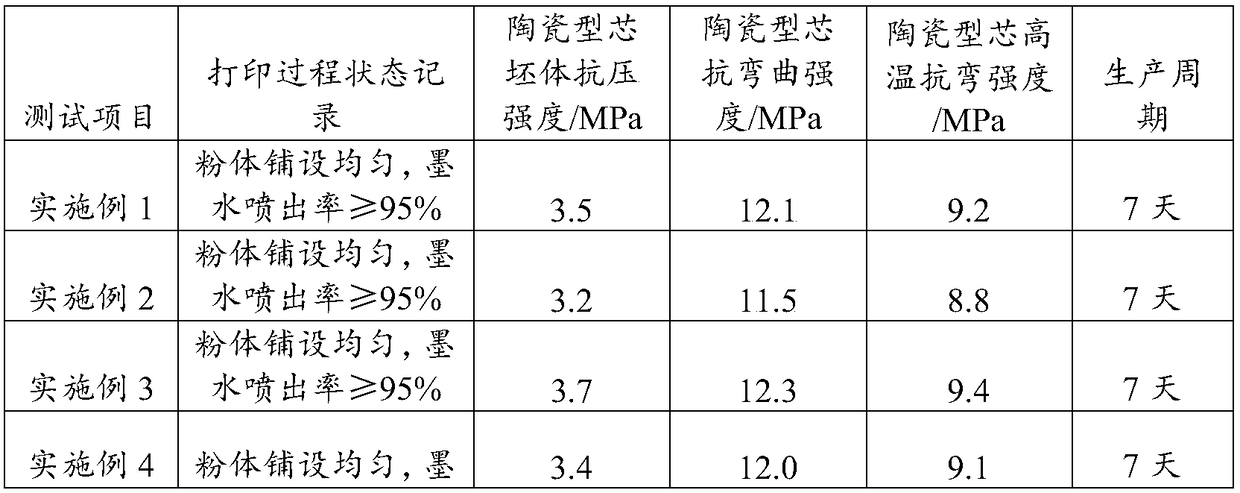

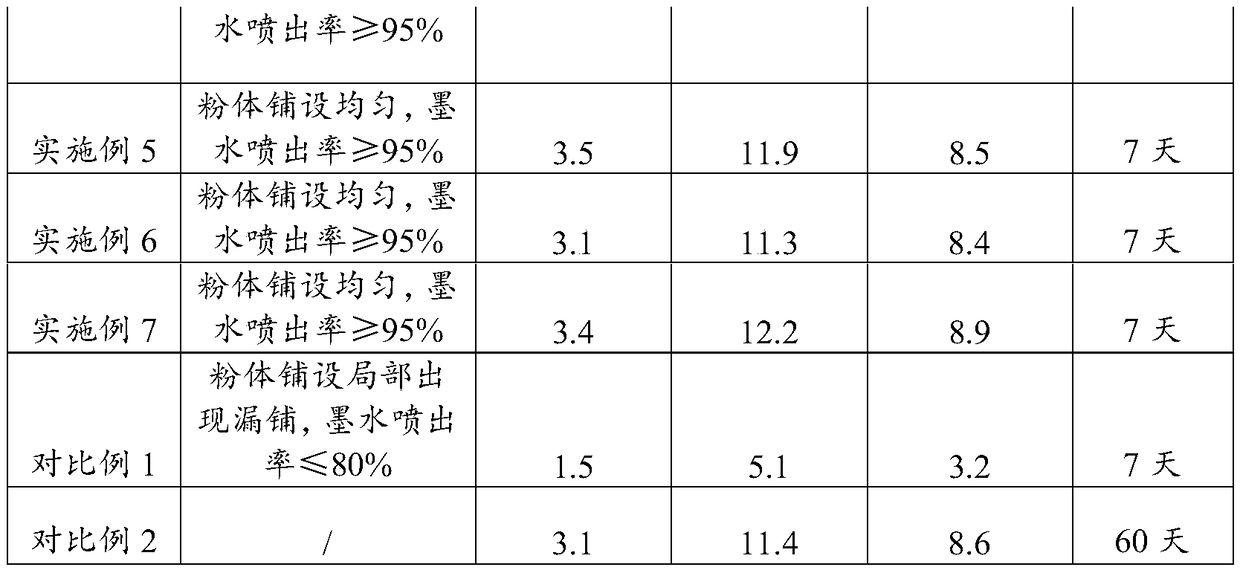

Examples

preparation example Construction

[0043] In a second aspect, the present invention provides a method for preparing a printing material for a ceramic core, comprising the following steps:

[0044] A) Granulating the mixture of refractory aggregate and reinforcing agent to obtain powder I;

[0045] B) Mix hardener and dispersant to obtain powder II;

[0046] C) Mixing powder I and powder II and sieving to obtain the molded powder.

[0047] In the preparation method provided by the present invention, the refractory aggregate and the reinforcing agent are first mixed and granulated to obtain powder I, the hardener and the dispersant are mixed to obtain powder II, and then the obtained powder I and powder II are mixed to obtain Formed powder. In the preparation method, the refractory aggregate and the reinforcing agent are mixed first, and the two are fully contacted to obtain a powder with good fire resistance and high compressive strength. It is then mixed with hardeners and dispersants to improve the printabi...

Embodiment 1

[0058] This embodiment is a printing material for a ceramic core, including a molding powder and a liquid binder; wherein, in parts by weight, the molding powder includes 89.24 parts of mullite powder, 7.76 parts of aluminum dihydrogen phosphate powder, 1.5 parts of magnesium and 1.5 parts of fumed silicon dioxide; the liquid binder includes 82.74 parts of aluminum dihydrogen phosphate liquid, 15.76 parts of phosphoric acid solution with a mass fraction of 15% and 1.5 parts of sodium dodecylbenzenesulfonate.

[0059] Wherein, in the aluminum dihydrogen phosphate liquid, the mass content of phosphorus pentoxide is 35%, and the mass content of aluminum oxide is 10%.

[0060] The preparation method of the printing material for the ceramic core in this embodiment includes the following steps:

[0061] A) Evenly mix mullite powder, aluminum dihydrogen phosphate powder and 50 parts of distilled water, stir to obtain a slurry, and use a spray granulator to granulate to obtain a powde...

Embodiment 2

[0069] This embodiment is a printing material for a ceramic core, including a molding powder and a liquid binder; wherein, in parts by weight, the molding powder includes 90 parts of mullite powder, 5 parts of aluminum dihydrogen phosphate powder, 2.5 parts of magnesium and 2.5 parts of fumed silicon dioxide; the liquid binder includes 88 parts of aluminum dihydrogen phosphate liquid, 10 parts of phosphoric acid solution with a mass fraction of 15% and 2 parts of sodium dodecylbenzenesulfonate.

[0070] Wherein, in the aluminum dihydrogen phosphate liquid, the mass content of phosphorus pentoxide is 35%, and the mass content of aluminum oxide is 10%.

[0071] The preparation method of the printing material for the ceramic core in this embodiment is the same as the preparation method of the printing material for the ceramic core provided in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com