Apparatus and method for preparing ice particle gas jet from supercooled water

A technology of gas jet and supercooled water, which is applied in the direction of used abrasive processing devices, explosion generating devices, and equipment that generates abrasive jets in a non-mechanical way, and can solve problems such as unsuitable control, large energy consumption, and stickiness , to achieve the effect of reducing the cost of jet operation, improving efficiency and precision, and uniform shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

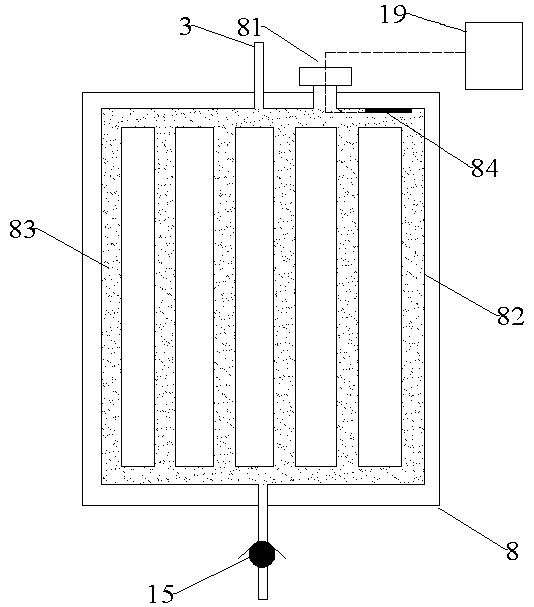

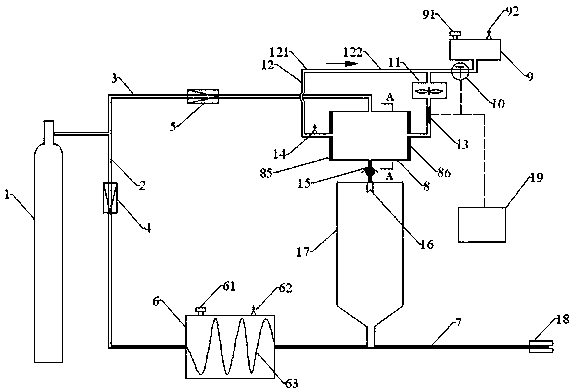

[0027] Such as figure 1 and figure 2 A device for preparing ice particle gas jets using supercooled water is shown, including air flow circulation 12, wherein the air flow circulation 12 is connected to the high-pressure gas cylinder 1 through the second branch pipeline 3, and is connected to the mist in the atomization chamber 17 through the pipeline 121. The atomization nozzle 16 is connected, wherein the bottom end of the atomization chamber 17 is connected with the confluence pipe 7, one end of the confluence pipe 7 is connected with the first liquid nitrogen tank 6, and the other end is connected with the nozzle 18, and the first liquid nitrogen tank 6 passes through the first branch pipeline 2. Connect with the high-pressure gas cylinder 1, wherein the wind flow circulation 12 includes the second liquid nitrogen tank 9, the bottom of the second liquid nitrogen tank 9 is connected with a pipeline 121, one end of the pipeline 121 is connected with the fan 11 through a tee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com