An integrated device and method for seawater desalination in-situ co-production of high-quality activated carbon

A high-quality, activated carbon technology, applied in chemical instruments and methods, seawater treatment, general water supply conservation, etc., can solve the problems of restricting the large-scale production of activated carbon, high production process costs, reducing service life, etc., and achieve high-value utilization. , easy to operate, reduce the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

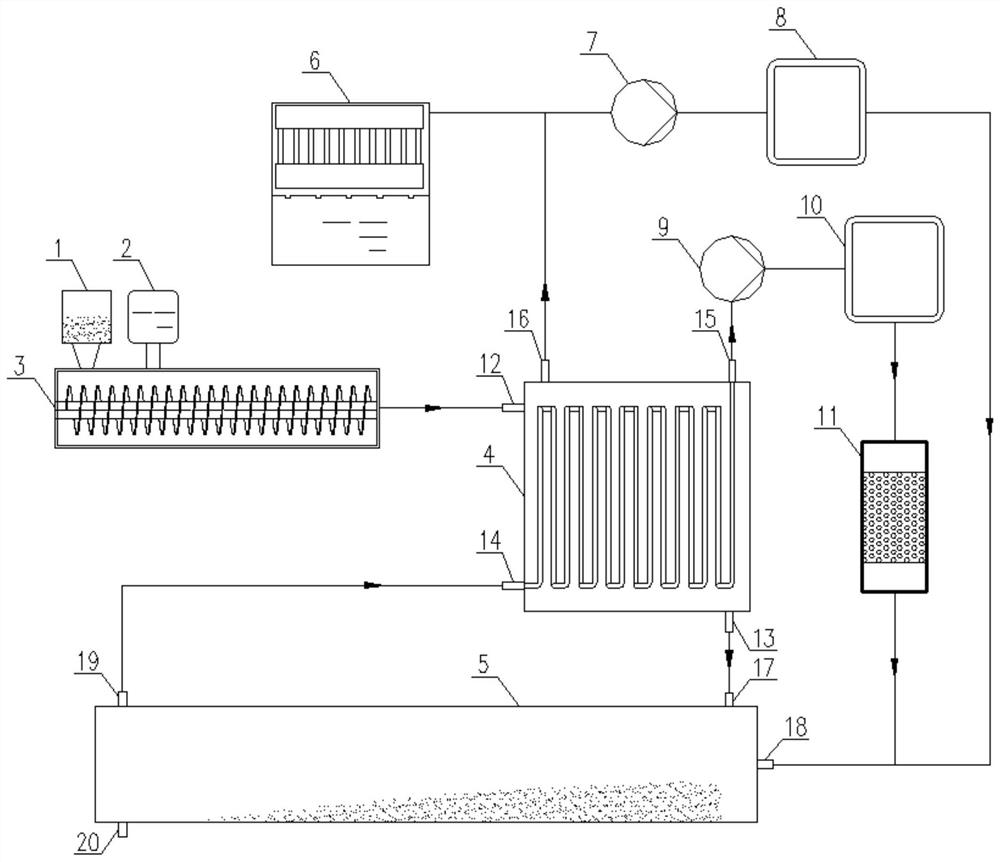

[0030]The marine solid waste enteromorpha is crushed into 100-mesh powder and then sent to the feeding device 3 from the silo 1 and seawater storage tank 2 respectively, and the biomass raw material and seawater are fully and uniformly mixed during the transmission process of the feeding device 3 , the residence time is set to 30min during the feeding process, and the mass ratio of Enteromorpha mass to seawater volume is adjusted to be 1:100. The mixed material in the feeding device 3 is sent to the partition heat exchange device 4 from the wet material inlet 12, and is mixed with the The high-temperature pyrolysis gas in the type pyrolysis and activation integrated device 5 performs indirect heat exchange. The pyrolysis gas goes inside the pipe, and the wet material goes outside the pipe. The moisture contained in the wet material is evaporated. The outlet 16 is sent to the condensation recovery device 6 and the pressurization device A7 respectively. The evaporation and concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com