A porous photothermal film with antibacterial properties and its preparation and application

A performance, photothermal technology, applied in the direction of coating, etc., can solve the problems of reduced water vapor output, complicated preparation methods, low porosity, etc., and achieve the effects of reducing heat loss, simple operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

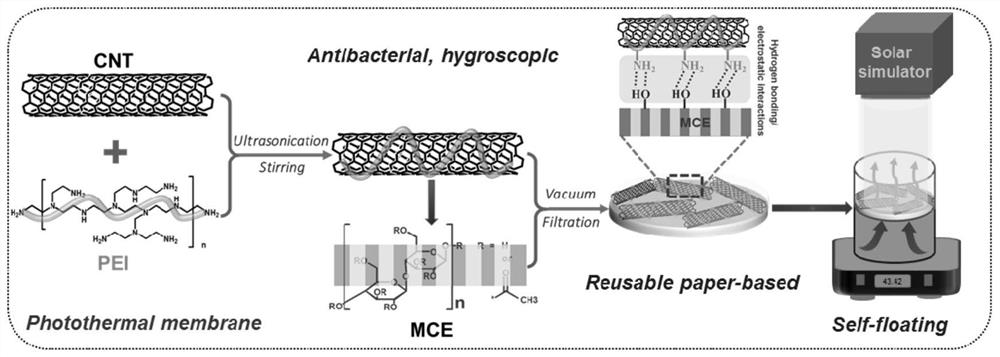

[0037] 2 mg of carbon nanotubes (Shanghai Aladdin Biochemical Technology Co., Ltd.) was added to 20 mL of deionized water containing 25 mg of polyethyleneimine (Shanghai Aladdin Biochemical Technology Co., Ltd., M.W. 70,000), and treated with stirring for 30 min and ultrasonication for 2 h. A uniform dispersion was obtained, and then the dispersion was filtered on a mixed cellulose ester filter membrane (Shanghai Luna Biotechnology Co., Ltd.) with a diameter of 47 mm and a pore size of 0.22 μm by vacuum filtration. Dry for about 12 hours.

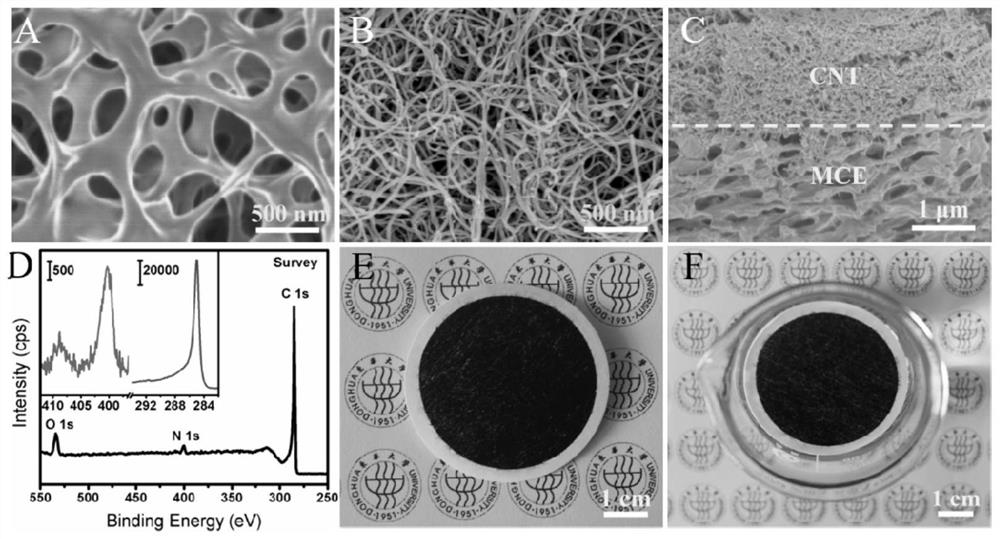

[0038] figure 2 The SEM (A-C) and XPS (D) spectra of the CNT@PEI / MCE photothermal film provided for the examples of the present invention and its optical photos (E, F), it can be seen from the pictures (A-C) that CNTs are uniformly distributed in the porous on the MCE film with a thickness of about 1.6 μm, typical CNTsp appeared in (D) 2 -Hybridized C peak (284.5 eV) and C-NH of PEI 2 (400.3 eV), (E, F) show that the obtained black photot...

Embodiment 2

[0040] Add 4 mg of carbon nanotubes to 20 mL of deionized water containing 50 mg of polyethyleneimine, stir for 1 h and ultrasonically treat for 2 h to obtain a uniform dispersion, and then use vacuum filtration to filter the dispersion to a mixed fiber with a pore size of 0.22 μm. The resulting photothermal film was dried at room temperature for about 12 hours.

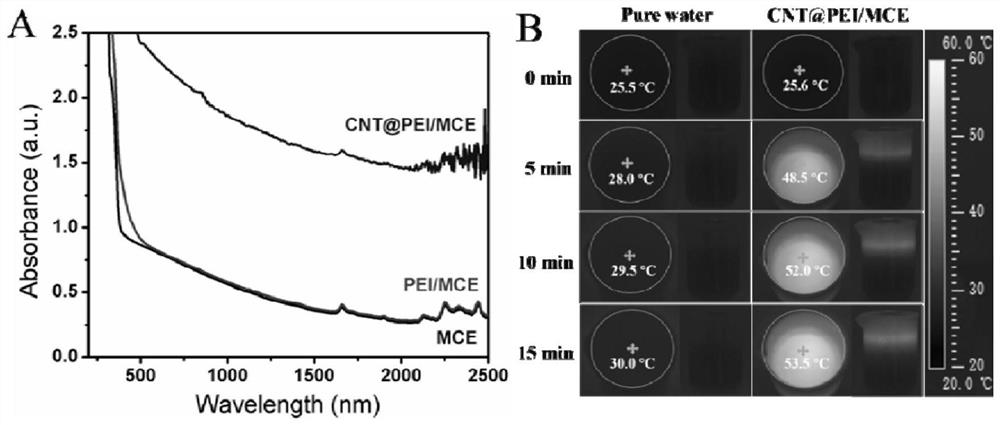

[0041] image 3 The optical spectrum and infrared thermal image of the CNT@PEI / MCE photothermal film provided in the embodiment of the present invention, image 3 A shows that the CNT@PEI / MCE film material has a good absorption of light in the wavelength range of 200nm to 2500nm and image 3 In B, it can be seen that the heat management of the entire photothermal film is concentrated at the interface during the illumination process, and the MCE substrate has a low thermal conductivity (0.565W m -1 K -1 ) reduces the loss of heat and effectively improves the utilization rate of solar energy.

Embodiment 3

[0043] Add 2 mg of carbon nanotubes to 10 mL of deionized water containing 50 mg of polyethyleneimine, stir for 1 h and ultrasonically treat for 2 h to obtain a uniform dispersion, and then use vacuum filtration to filter the dispersion into mixed fibers with a pore size of 0.22 μm. The resulting photothermal film was dried at room temperature for about 12 hours.

[0044] Figure 4 It was shown that the contact angle of the CNT layer rapidly decreased to 0° within 60 s after grafting PEI, suggesting that its Wenzel’s wetting behavior (sufficient contact with the hot spot) might originate from the synergistic effect of the hygroscopicity of PEI and the surface roughness of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com