Modified montmorillonoid, preparation method and composite material

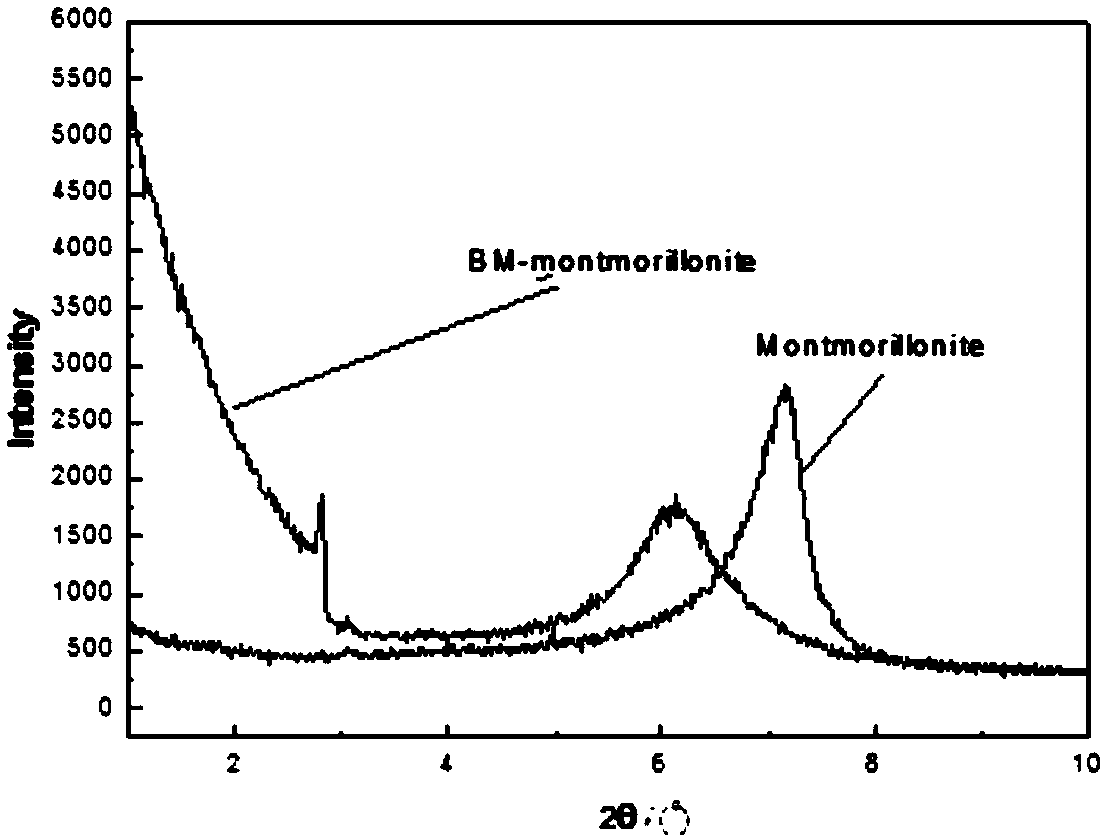

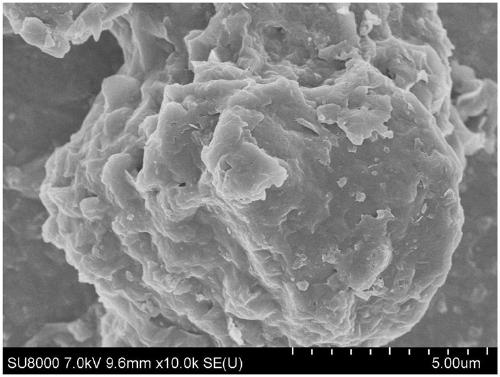

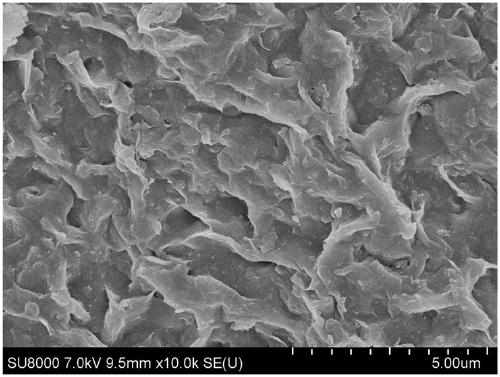

A composite material and montmorillonite technology, applied in the field of inorganic fillers, can solve the problems such as no biological method precedent, and achieve the effects of improving the activity of montmorillonite, improving surface roughness, tensile strength and elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of modified montmorillonite, comprising:

[0039] adding montmorillonite and deionized water into the culture medium for sulfate-reducing bacteria, and mixing evenly, wherein the amount of montmorillonite added is 80%, and the amount of deionized water added is 90% of the total mass of the medium;

[0040] Add 25% of the total mass of sulfate-reducing bacteria to the above-mentioned sulfate-reducing bacteria culture medium, and culture with shaking at 30°C for 168 hours under anaerobic or a small amount of oxygen environment;

[0041] After the cultivation is completed, the solid-liquid separation is carried out, and the modified montmorillonite is obtained by drying.

Embodiment 2

[0043] In this example, the difference from Example 1 is that the addition amount of montmorillonite is 80%, the addition amount of deionized water is 5%, the addition amount of sulfate-reducing bacteria is 1%; 0 ℃ shaking culture 3h .

Embodiment 3

[0045] In this example, the difference from Example 1 is that the addition of montmorillonite is 1%, the addition of deionized water is 20%, the addition of sulfate-reducing bacteria is 50%; 60 ° C shaking culture 168h .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com