Transparent flame-retardant polycarbonate material for two-color injection molding, and preparation method thereof

A technology of flame-retardant polycarbonate and two-color injection molding, which is applied in the field of transparent flame-retardant polycarbonate materials and its preparation, to achieve the effects of strong operability, excellent flame retardancy and high temperature resistance, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

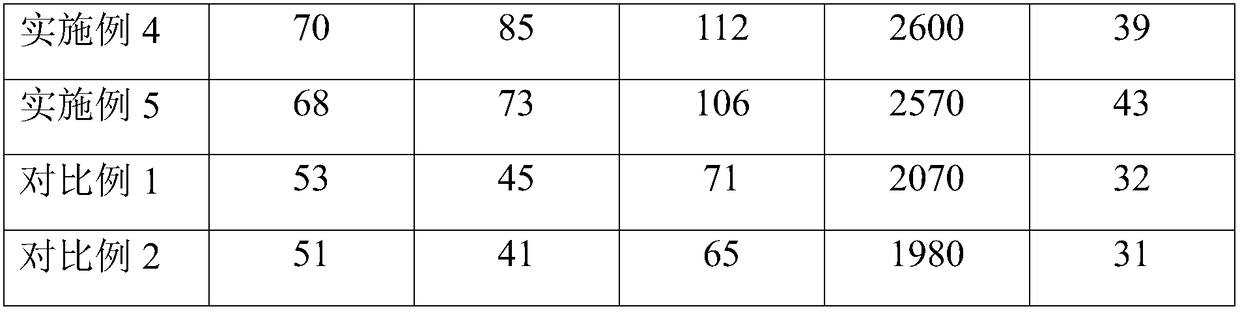

Examples

preparation example Construction

[0023] The present invention also provides a method for preparing a transparent flame-retardant polycarbonate material for two-color injection molding, comprising the following steps:

[0024] After mixing polycarbonate resin, antioxidant and solid flame retardant evenly, put it into the hopper of the twin-screw extruder, and add a liquid flame retardant with a temperature of 60 to 80 ° C at the side feeding place; then melt extrusion, After water cooling and pelletizing, a transparent flame-retardant polycarbonate material for two-color injection molding is obtained.

[0025] In order to prevent the PC resin from turning yellow due to strong shearing and affecting the transparency and aesthetic appearance of the PC resin, the present invention uses a twin-screw extruder with weak shear to process the raw materials. Under optimal conditions, the twin-screw extruder The extruder is a Coperion 75 machine.

[0026] In the present invention, in the feeding process, the use of pre...

Embodiment 1

[0035] A transparent flame-retardant polycarbonate material for two-color injection molding, which is made of the following substances: 85 parts by weight of polycarbonate resin 2000F, 5 parts by weight of tricresyl phosphate, 10 parts by weight of aluminum hydroxide (average particle size is 30 μm ), 0.1 part by weight of tris(2,4-di-tert-butylphenyl) phosphite.

[0036] 85 parts by weight of polycarbonate resin 2000F, 10 parts by weight of aluminum hydroxide, 0.1 part by weight of tris(2,4-di-tert-butylphenyl) phosphite were uniformly put into the hopper of the twin-screw extruder after being homogenized by a high mixer. At the same time, a high-pressure liquid pump was used to pump 5 parts by weight of tricresyl phosphate with a temperature of 80°C into the twin-screw extruder at a flow rate of 70kg / h from the side feeder, and the temperature of the screw barrel was set to 270°C, melting The body temperature is 260 °C, the screw speed is 500 r / min, and the vacuum degree is ...

Embodiment 2

[0038] A transparent flame-retardant polycarbonate material for two-color injection molding, which is made of the following materials: 100 parts by weight of polycarbonate resin 3000F, 0.05 parts by weight of triisobutyl phosphate, 0.05 parts by weight of aluminum hydroxide (average particle size is 25 μm), 0.1 part by weight of tris(2,4-di-tert-butylphenyl)phosphite.

[0039]Put 100 parts by weight of carbonate resin 3000F, 0.1 part by weight of tris(2,4-di-tert-butylphenyl) phosphite and 0.05 part by weight of aluminum hydroxide into the hopper of the twin-screw extruder after uniformly passing through a high mixer, At the same time, a high-pressure liquid pump was used to pump 0.05 parts by weight of triisobutyl phosphate with a temperature of 60°C into the twin-screw extruder at a flow rate of 60kg / h from the side feeder. The temperature of the screw barrel was set to 230°C, and the melt The body temperature is 240°C, the screw speed is 300r / min, the vacuum degree is -0.04...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com