Graphene oxide modified environment-friendly polyurethane oil-based topcoat and preparation method thereof

A graphene-modified and environmentally friendly technology, applied in the field of polyurethane materials, can solve problems such as difficulty in solvent-free, poor aging resistance, and non-environmental protection, and achieve the effects of improving skeleton structure, excellent aging resistance, and good long-term usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

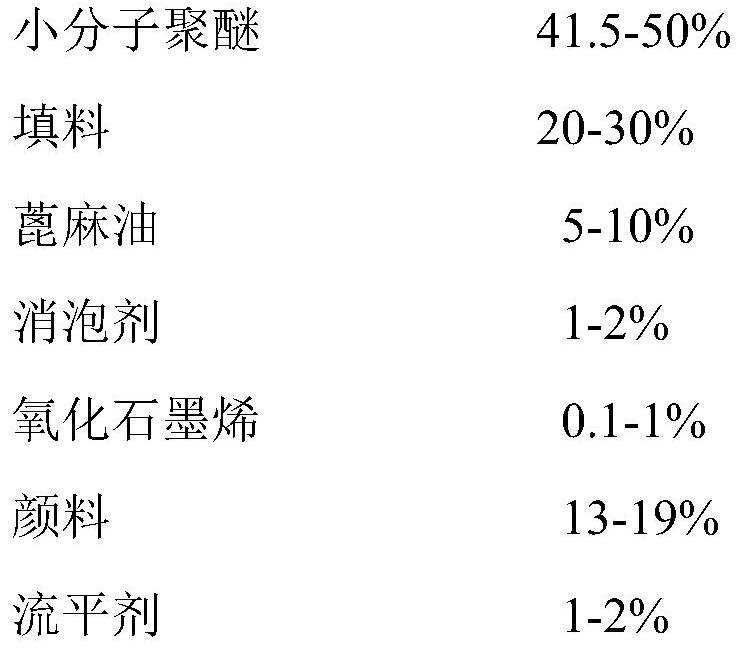

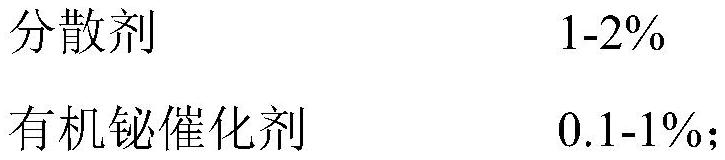

Method used

Image

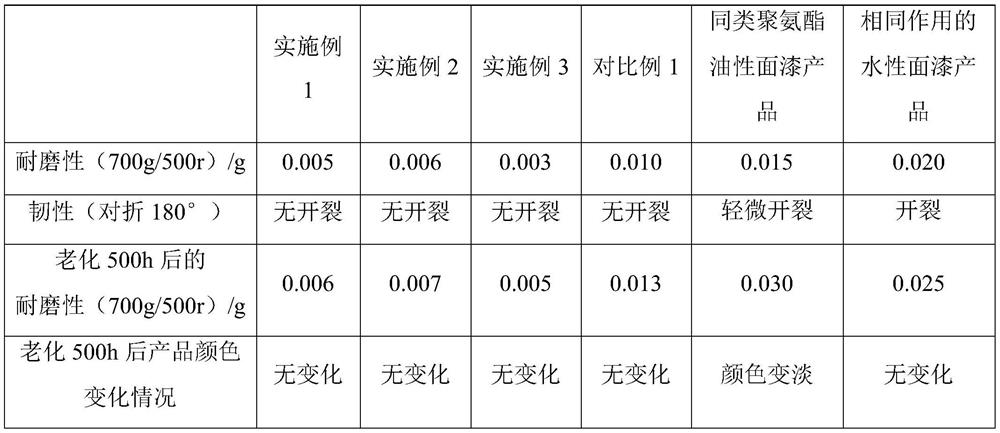

Examples

Embodiment 1

[0032] (1) Component A: Put 415g of polyether VORANOL 220-260 with a molecular weight of 400, 100g of dehydrated castor oil and 10g of dispersant YCK-2330 into the reactor, stir at 800 rpm for 15min, then add 10g of graphene oxide (graphite LC50 -9999 prepared by the Hummers method), stirred at 1000 rpm for 10 minutes, then added 20 g of leveling agent YCK-1190, 130 g of iron oxide red 130, 300 g of 4000 mesh talc powder, stirred at 1000 rpm for 15 min, and then added 5 g of organic bismuth Catalyst Kat24 and 5g defoamer RJ-4040, stirred at 1200 rpm for 25 minutes, finally added 5 g of defoamer RJ-4040, stirred at 1800 rpm for 15 minutes, and prepared component A in barrels;

[0033] (2) Component B: react 380g of polyether VORANOL4240 with a molecular weight of 4000 and 720g of isocyanate HMDI at 85°C for 2h to obtain a prepolymer, and the final percentage of isocyanate is 22%.

[0034] (3) During construction, mix component A and component B evenly and then roll coat on the ...

Embodiment 2

[0037] (1) Component A: Put 500g of polyether VORANOL 230-238 with a molecular weight of 700, 50g of dehydrated castor oil and 20g of dispersant YCK-2330 into the reactor, stir at 1000 rpm for 10min, then add 5g of graphene oxide (graphite LC50 -9999 prepared by the Hummers method), stirred at 800 rpm for 15 minutes, then added 14g of leveling agent YCK-1190, 190g of iron oxide red 130, 200g of 4000 mesh talcum powder under stirring, stirred at 800 for 20min, and then added 1g of organic bismuth Catalyst Kat24 and 10g of defoamer RJ-4040, stirred at 1500 rpm for 20 minutes, finally added 10 g of defoamer RJ-4040, stirred at 1500 rpm for 20 minutes, and prepared component A in barrels;

[0038] (2) Component B: 320 g of polyether VORANOL4701 with a molecular weight of 5000 and 680 g of isocyanate HMDI were reacted at 75° C. for 2.5 hours to obtain a prepolymer, and the final percentage of isocyanate was 21%.

[0039] (3) During construction, mix component A and component B even...

Embodiment 3

[0042] (1) Component A: Put 469g of polyether VORANOL 2110TB with a molecular weight of 1000, 70g of dehydrated castor oil and 15g of dispersant YCK-2330 into the reactor, stir at 900 rpm for 13min, then add 1g of graphene oxide (graphite LC50-9999 Prepared by the Hummers method), stirred at 900 rpm for 13 minutes, then added 10 g of leveling agent YCK-1190, 160 g of iron oxide red 130, and 250 g of 4000 mesh talcum powder under stirring, stirred at 900 rpm for 18 min, and then added 10 g of organic bismuth catalyst Kat24 and 7.5g of antifoaming agent RJ-4040, stirred at 1400 rpm for 23 minutes, finally added 7.5g of antifoaming agent RJ-4040, stirred at 1600 rpm for 17 minutes, and prepared component A in barrels;

[0043](2) Component B: react 330g polyether VORANOL3010 with a molecular weight of 3000 and 670g isocyanate HMDI at 80°C for 2.3h to obtain a prepolymer, and the final percentage of isocyanate is 20%.

[0044] (3) During construction, mix component A and component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com