Preparation method of wear-resistant self-lubricating coating for iron and steel materials

A self-lubricating coating, steel material technology, applied in the direction of metal material coating process, coating, device for coating liquid on the surface, etc. problems, to achieve the effect of increasing self-lubricating performance, improving fatigue resistance, and improving friction and wear life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of wear-resistant self-lubricating coating for iron and steel materials. The sample material is 35 steel, the size is 100mm×50mm×5mm, the surface is milled to a roughness Ra≤1.6, and it is ready for use.

[0069] ① Soak the test piece in an organic solvent such as acetone or ethyl acetate for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 80±5°C for 30 minutes; then rinse it with tap water for 30s-60s.

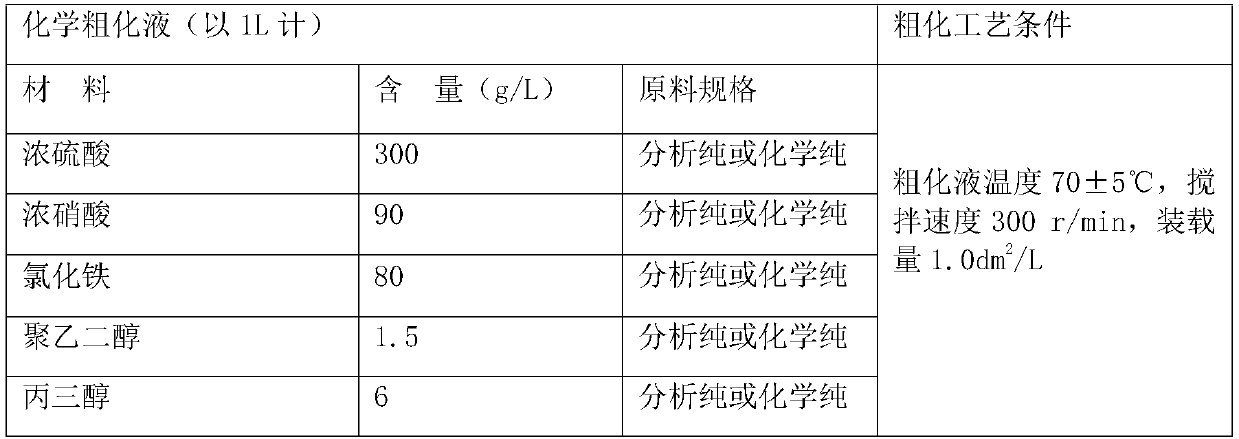

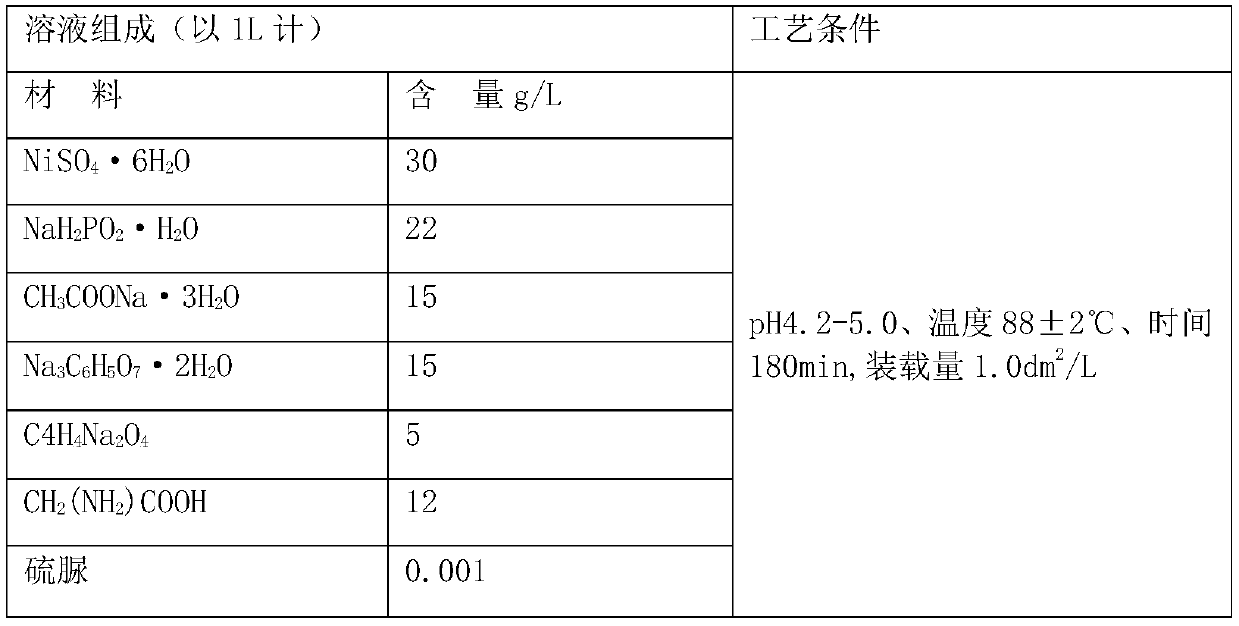

[0070] ②Chemical roughening treatment: perform chemical roughening treatment according to the chemical roughening solution and process conditions shown in Table 1; the treatment time is 60 minutes, then rinse with tap water for 60 seconds, and dry.

[0071] Table 1 Composition and process conditions of chemical roughening solution

[0072]

[0073] Remarks, the content of the concentrated sulfuric acid is 300g / L, specifically 300g of concentrated sulfuric acid per 1L of solution, and 90g / L of co...

Embodiment 2

[0081] Preparation of wear-resistant and self-lubricating coatings for steel materials. The sample material is 30CrMnSiA, the size is 100mm×50mm×5mm, and the surface is milled to a roughness of Ra≤1.6. It is ready for use.

[0082] ① Soak the test piece in an organic solvent such as acetone or ethyl acetate for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 80±5°C for 30 minutes; then rinse it with tap water for 30s-60s.

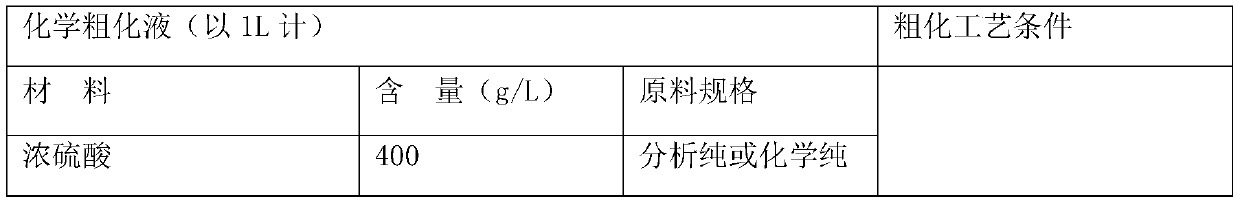

[0083] ②Chemical roughening treatment: perform chemical roughening treatment according to the chemical roughening solution and process conditions shown in Table 3; the treatment time is 120 minutes, then rinse with tap water for 60 seconds, and dry.

[0084] Table 3 Composition and process conditions of chemical roughening solution

[0085]

[0086]

[0087] Remarks, the content of the concentrated sulfuric acid is 400g / L, specifically 400g of concentrated sulfuric acid per 1L of solution, an...

Embodiment 3

[0095] Preparation of wear-resistant and self-lubricating coatings for iron and steel materials. The sample material is 30SiMn2MoVA, the size is 100mm×50mm×5mm, and the surface is milled to a roughness of Ra≤1.6. It is ready for use.

[0096] ① Soak the test piece in an organic solvent such as acetone or ethyl acetate for 2 minutes, then wipe it clean with absorbent cotton; then degrease it in an alkaline degreasing solution at 80±5°C for 30 minutes; then rinse it with tap water for 30s-60s.

[0097] ②Chemical roughening treatment: perform chemical roughening treatment according to the chemical roughening solution and process conditions shown in Table 5; the treatment time is 120 minutes, then rinse with tap water for 60 seconds, and dry.

[0098] Table 5 Composition and process conditions of chemical roughening solution

[0099]

[0100] Remarks, the content of the concentrated sulfuric acid is 270g / L, specifically 270g of concentrated sulfuric acid per 1L of solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com