A microwave-driven infinite ultraviolet combined catalytic combustion method and equipment for treating vocs gas

A catalytic combustion, electrodeless ultraviolet technology, applied in the combustion method, lighting and heating equipment, combustion type and other directions, can solve the problem of energy consumption and no better solution, achieve good catalytic decomposition effect, reduce secondary pollutants Emissions and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

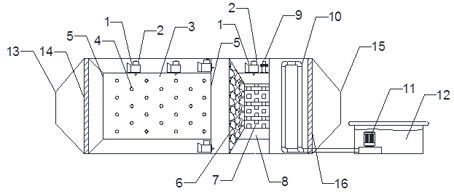

[0043] Exhaust gas parameters: flow rate 800~1000m 3 / h, the pollutant component is toluene, the concentration is 30~60ppm;

[0044] Equipment parameters: The ultraviolet photolysis module contains 11 185nm electrodeless ultraviolet lamps, each with a rated power of 65w, the output power of the microwave generator 1 is 300~420w, and the gas residence time is 2~5s; the temperature of the preheated bed layer 6 in the catalytic combustion module 220~300℃, the temperature of the catalytic combustion bed 7 is 220~300℃, and the gas residence time is 0.4~1.2s;

[0045] When the exhaust gas treatment device is running, the microwave generator 1 in the ultraviolet photolysis module operates stably at the set power, and the output power of the microwave generator 1 in the catalytic combustion module transmits the electrical signal to the control device through the infrared temperature sensor 9, and finally the frequency conversion high voltage The driver 2 is adjusted to control the te...

Embodiment 2

[0047] Exhaust gas parameters: flow rate 400~600m 3 / h, the pollutant component is toluene, the concentration is 480~520ppm;

[0048] Equipment parameters: The ultraviolet photolysis module contains 11 185nm electrodeless ultraviolet lamps, each with a rated power of 65w, the output power of the microwave generator 1 is 300~420w, and the gas residence time is 4~8.5s; the preheating bed layer 6 in the catalytic combustion module The temperature is 220~300°C, the temperature of the catalytic combustion bed 7 is 220~300°C, and the gas residence time is 0.8~2s;

[0049] When the exhaust gas treatment device is running, the microwave generator 1 in the ultraviolet photolysis module operates stably at the set power, and the output power of the microwave generator 1 in the catalytic combustion module transmits the electrical signal to the control device through the infrared temperature sensor 9, and finally the frequency conversion high voltage The driver 2 is adjusted to control th...

Embodiment 3

[0055] Exhaust gas parameters: flow rate 800~1000m 3 / h, the pollutant component is isopropanol, the concentration is 120~1500ppm;

[0056] Equipment parameters: The ultraviolet photolysis module contains 11 185nm electrodeless ultraviolet lamps, each with a rated power of 65w, the output power of the microwave generator 1 is 300~420w, and the gas residence time is 2~5s; the temperature of the preheated bed layer 6 in the catalytic combustion module 220~300℃, the temperature of the catalytic combustion bed 7 is 220~300℃, and the gas residence time is 0.4~1.2s;

[0057] When the exhaust gas treatment device is running, the microwave generator 1 in the ultraviolet photolysis module operates stably at the set power, and the output power of the microwave generator 1 in the catalytic combustion module transmits the electrical signal to the control device through the infrared temperature sensor 9, and finally the frequency conversion high voltage The driver 2 is adjusted to control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com