Preparation method for high-sulfur, high-sodium and high-level-liquid-waste glass-ceramic solidifier

A technology of high-level radioactive waste liquid and glass ceramics, applied in radioactive purification, nuclear engineering, etc., can solve the problem of yellow phase and achieve the effect of good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a high-sulfur, high-sodium, high-level radioactive waste liquid glass-ceramic solidified body, the steps are:

[0033] a. Prepare barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid: add Ba(NO 3 ) 2 solution, control SO 4 2- and Ba 2+ The molar ratio is 1:1, and the high-sulfur, high-sodium and high-level radioactive waste liquid containing barite is obtained;

[0034] b. Ingredients: according to SiO 2 54.0%, B 2 o 3 20.0%, Na 2 O 4.5%, CaO 5.0%, Al 2 o 3 3.5%, MgO1.5%, TiO 2 1.5%, the component composition and mass percentage of 10% of the barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid calculated as waste oxides are taken from each component;

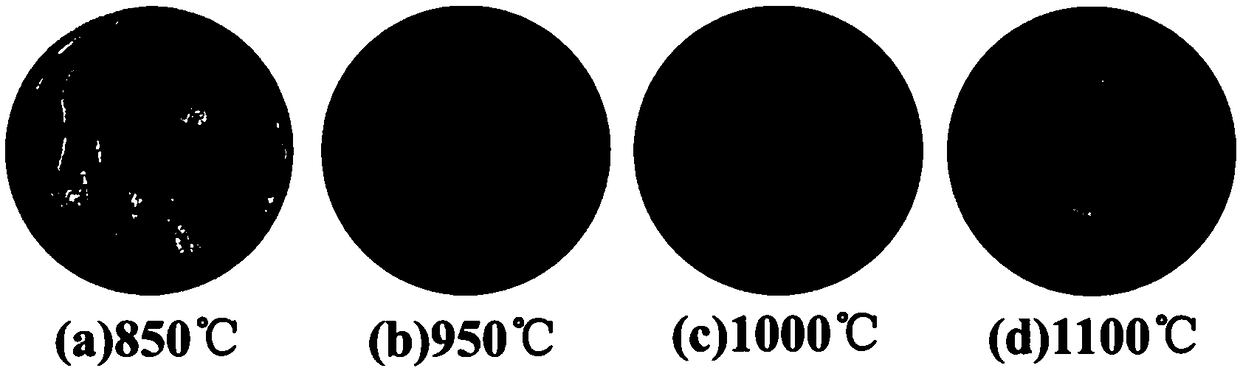

[0035] c. Mixing reaction: After mixing the raw materials, put them in a furnace (for example: muffle furnace or glass melting furnace, etc.) and heat-preserve and calcinate at 850°C for 1h (to decompose the carbonate); then...

Embodiment 2

[0037] A method for preparing a high-sulfur, high-sodium, high-level radioactive waste liquid glass-ceramic solidified body, the steps are:

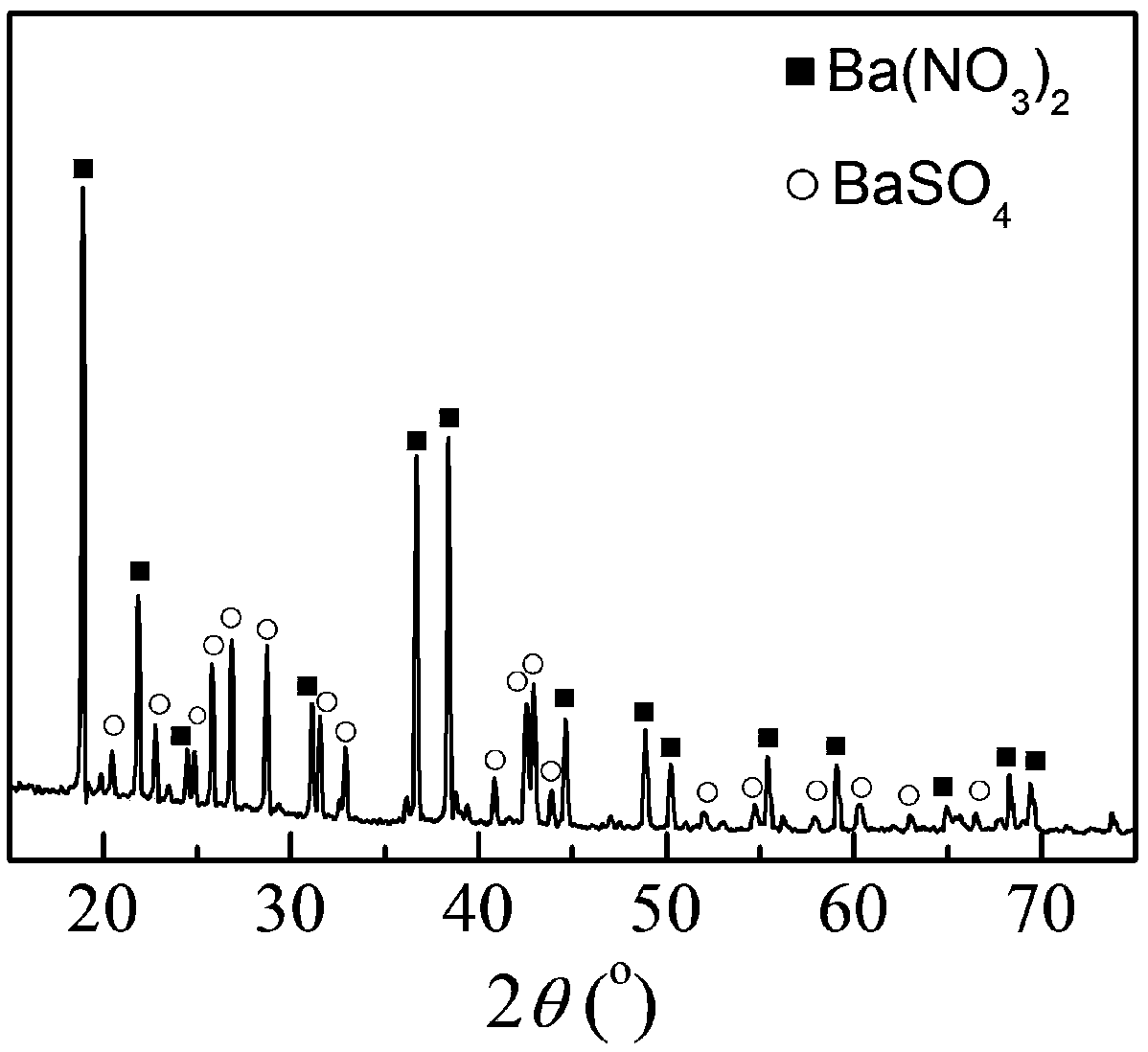

[0038] a. Prepare barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid: add Ba(NO 3 ) 2 solution, control SO 4 2- and Ba 2+ The molar ratio is 1:1.2, and the high-sulfur, high-sodium and high-level radioactive waste liquid containing barite is obtained (the XRD of the sediment is shown in the attached figure 1 shown);

[0039] b. Ingredients: according to SiO 2 52.8%, B 2 o 3 19.6%, Na 2 O 4.4%, CaO 4.9%, Al 2 o 3 3.4%, MgO1.45%, TiO 2 1.45%, the component composition and mass percentage of the barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid 12% in terms of waste oxides are taken from each component;

[0040] c. Mixing reaction: After mixing the raw materials, put them in a furnace (for example: muffle furnace or glass melting furnace, etc.) and heat-preserv...

Embodiment 3

[0042] A method for preparing a high-sulfur, high-sodium, high-level radioactive waste liquid glass-ceramic solidified body, the steps are:

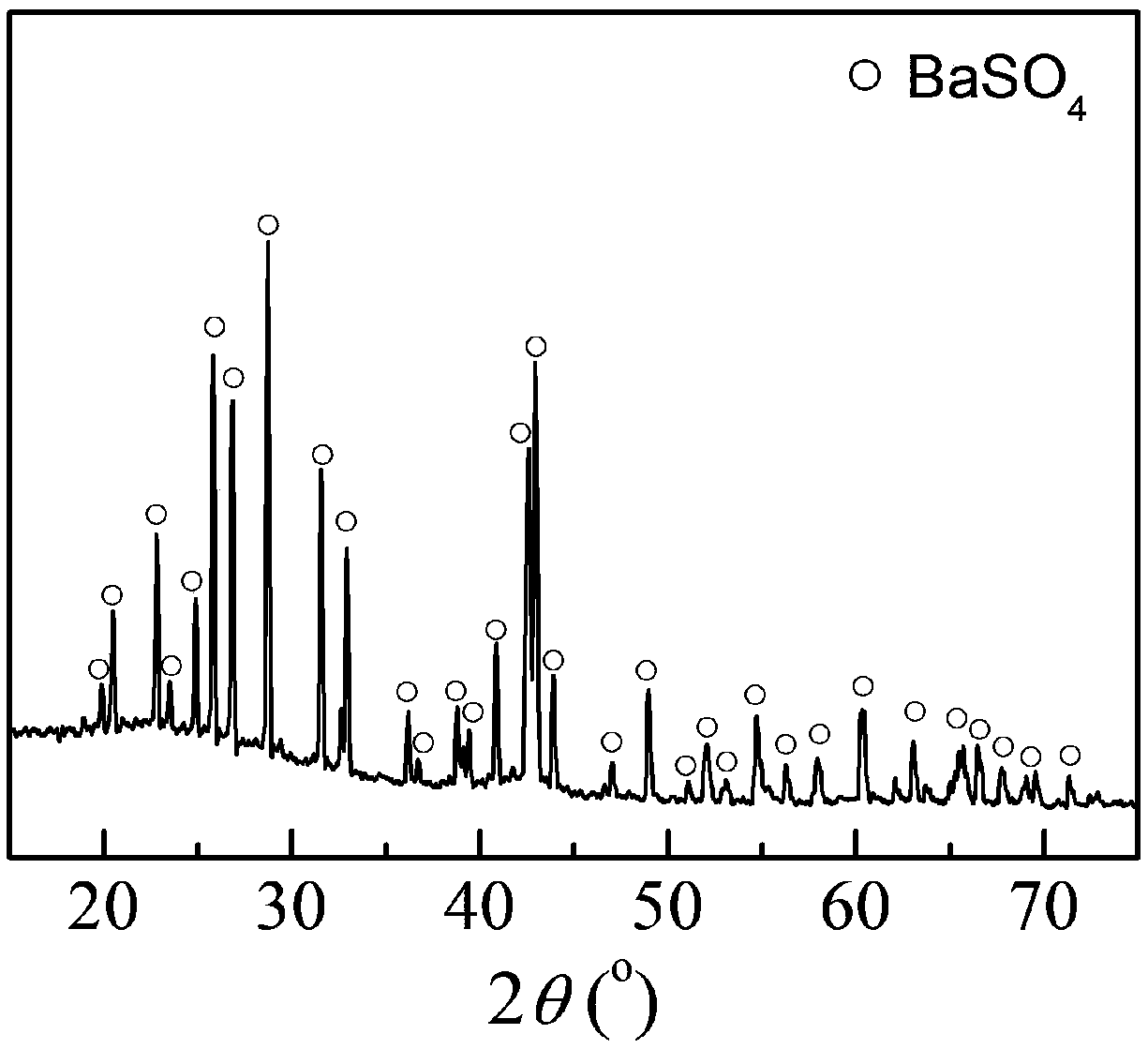

[0043] a. Prepare barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid: add Ba(NO 3 ) 2 solution, control SO 4 2- and Ba 2+ The molar ratio is 1:1.4, and the high-sulfur high-sodium high-level radioactive waste liquid containing barite and barium nitrate is obtained (the XRD of the sediment is shown in the attached figure 2 shown);

[0044] b. Ingredients: according to SiO 2 51.6%, B 2 o 3 19.1%, Na 2 O 4.3%, CaO 4.8%, Al 2 o 3 3.36%, MgO1.42%, TiO 2 1.42%, the component composition and mass percentage of the barite-containing high-sulfur, high-sodium and high-level radioactive waste liquid 14% in terms of waste oxides are taken from each component;

[0045] c. Mixing reaction: After mixing the raw materials, put them in a furnace (for example: muffle furnace or glass melting furnace, etc.) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com