A kind of silver nanowire composite graphene memristor and preparation method thereof

A technology of composite graphene and silver nanowires, applied in the direction of electric solid devices, electrical components, circuits, etc., can solve the problems of high cost, complicated preparation process, poor bending of memristors, etc., and achieve good elasticity and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The present invention also provides a preparation method of a silver nanowire composite graphene memristor, the preparation method comprising the following steps:

[0049] (1) Preparation of flexible first electrode layer: a) The PVDF piezoelectric film with a thickness of less than 300 μm is polarized by the silicon oil thermal polarization method, the thermal polarization electric field strength is 100-160MV / m, and the polarization temperature is 80-100 ℃, the polarization time is 60-120min, so that the non-polar α crystal form of the PVDF piezoelectric film changes to the polar β crystal form, and the piezoelectric performance of the PVDF piezoelectric film is improved; b) after the thermal polarization The upper surface of the PVDF piezoelectric film is plated with an indium tin oxide conductive layer with a thickness of 0.5-10 μm, and the conductive silver glue is used to paste the indium tin oxide conductive layer and the first copper wire together to lead out the ...

Embodiment 1

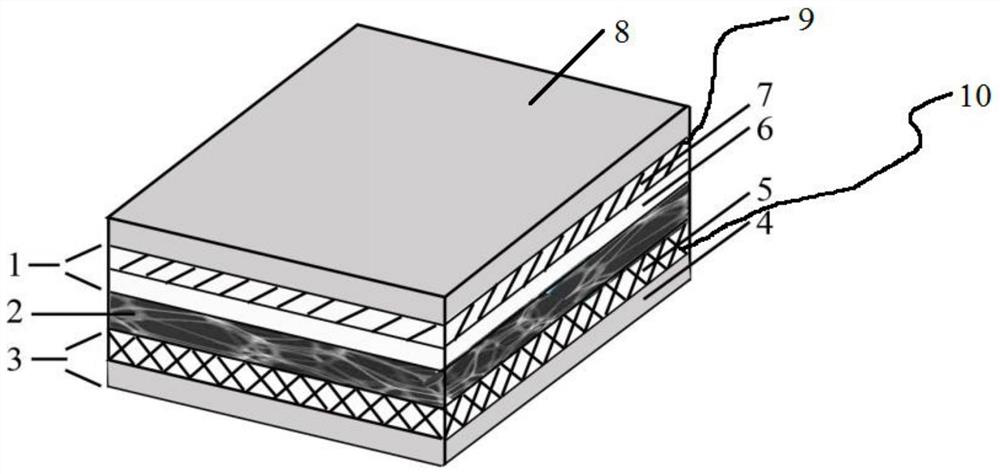

[0058] The structure of the silver nanowire composite graphene memristor based on the PVDF piezoelectric film prepared in Example 1 is as follows figure 1 As shown, it consists of a flexible first electrode layer 1, a silver nanowire composite graphene layer 2, a flexible second electrode layer 3, a bottom PEF film 4, a silver conductive layer 5, a PVDF piezoelectric film 6, and an indium tin oxide conductive film 7, The top layer of PEF film 8 is composed of a first electrode 9 and a second electrode 10;

[0059] (1) Preparation of flexible first electrode layer: a) The PVDF piezoelectric film with a thickness of less than 300 μm is polarized by the silicon oil thermal polarization method, the thermal polarization electric field strength is 100-160MV / m, and the polarization temperature is 80-100 ℃, the polarization time is 60-120min, so that the non-polar α crystal form of the PVDF piezoelectric film changes to the polar β crystal form, and the piezoelectric performance of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com