Nanosheet-shape potassium ion battery cathode material, preparation method thereof and potassium ion battery

A battery cathode and nanosheet technology, which is applied in the field of energy conversion materials, can solve the problems of blocking potassium ion migration, affecting electrochemical performance, affecting rate performance, etc., and achieves the effects of good cycle performance, low equipment requirements, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

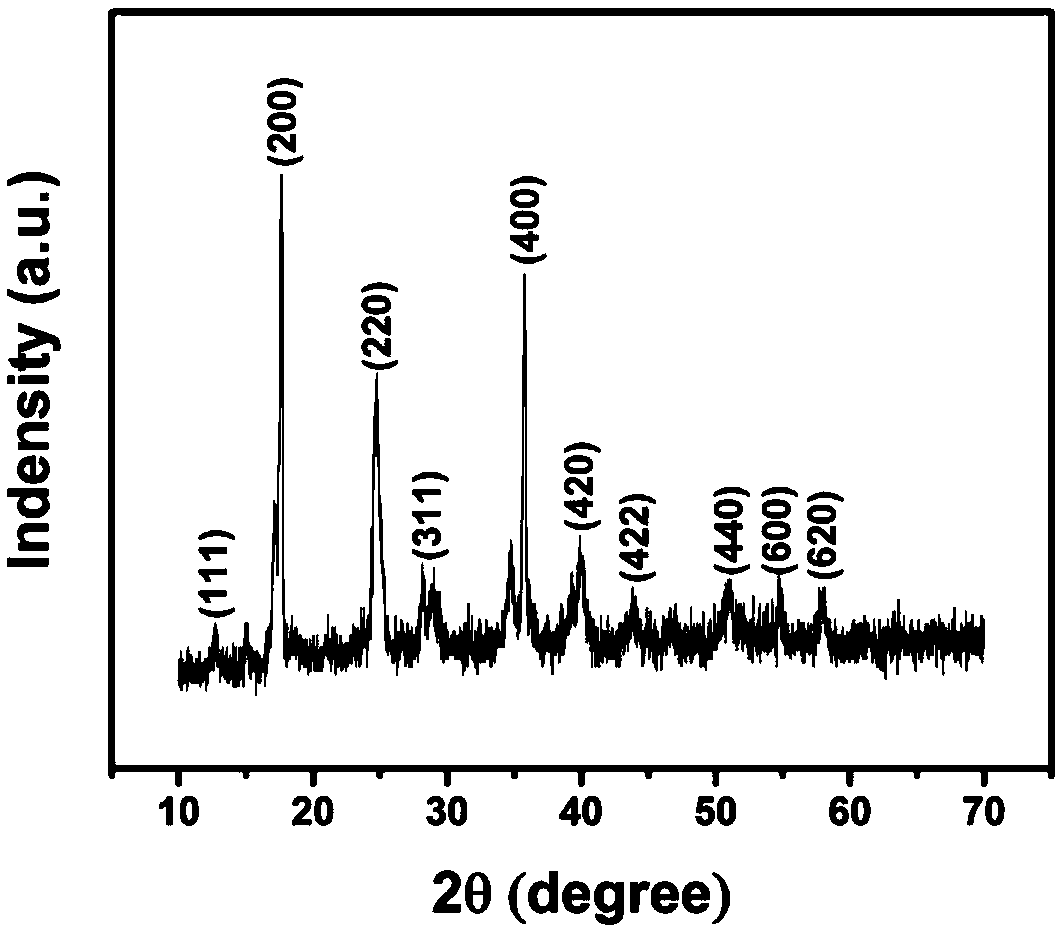

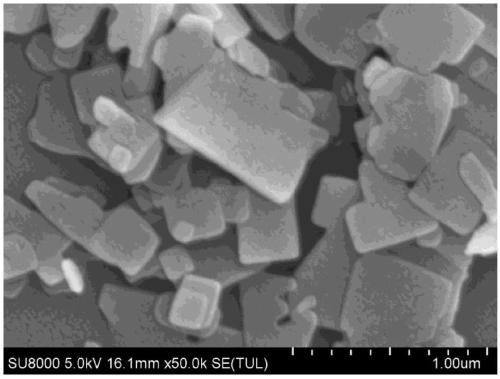

[0033] The molecular formula of the nanosheet-shaped potassium ion battery cathode material of the present embodiment is K 2 Cu[Fe(CN) 6 ], its specific preparation method comprises the steps:

[0034] S1: Dissolve potassium ferrocyanide in a deionized aqueous solution with a concentration of 0.6 mol / L, and place it in an ultrasonic generator with water as the propagation medium;

[0035] S2: Dissolve copper acetate in ethylene glycol solution at 55°C with a concentration of 0.4 mol / L;

[0036] S3: Use a syringe pump to drop the copper acetate alcohol solution into the potassium ferrocyanide aqueous solution at a rate of 2.5 ml / h to carry out the precipitation reaction. At the same time, apply ultrasonic waves with a power of 550 W. The reaction temperature rises, and the medium water in the ultrasonic device is replaced by circulating water, and the reaction temperature is controlled at about 30 °C; the volume ratio of the final reaction copper acetate alcohol solution to p...

Embodiment 2

[0040] The molecular formula of the nanosheet-shaped potassium ion battery cathode material provided in this embodiment is K 2 Cu 0.6 Zn 0.4 [Fe(CN) 6 ], its specific preparation steps are: (

[0041] S1: Dissolve potassium ferrocyanide in a deionized aqueous solution with a concentration of 0.4 mol / L, and place it in an ultrasonic generator with water as the propagation medium;

[0042] S2: Dissolve copper acetate and zinc nitrate in ethylene glycol solution at 55°C, and the total concentration of metal ions is 0.2 mol / L;

[0043] S3: Use a syringe pump to drop the mixed alcohol solution into the potassium ferrocyanide aqueous solution at a rate of 2 ml / h to carry out the precipitation reaction. At the same time, apply ultrasonic waves with a power of 600 W, and to adjust the The reaction temperature rises, and the medium water in the ultrasonic device is replaced by circulating water, and the reaction temperature is controlled at about 30 °C; the volume ratio of the fina...

Embodiment 3

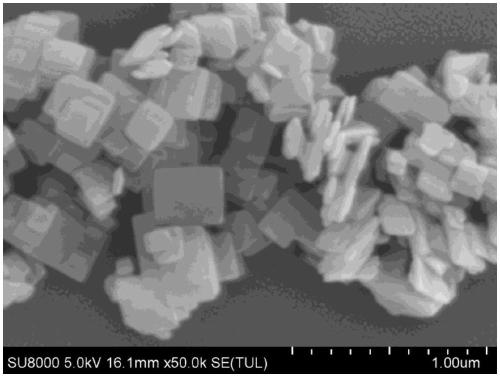

[0048] The molecular formula of the nanosheet-shaped potassium ion battery cathode material provided in this embodiment is K 2 Zn[Fe(CN) 6 ], its concrete preparation steps are as follows:

[0049] S1: Dissolve potassium ferrocyanide in a deionized aqueous solution with a concentration of 0.5 mol / L, and place it in an ultrasonic generator, using water as the propagation medium;

[0050] S2: Dissolve zinc nitrate in ethylene glycol solution at 55°C, and the total concentration of metal ions is 0.25 mol / L;

[0051] S3: Use a syringe pump to drop the mixed alcohol solution into the potassium ferrocyanide aqueous solution at a rate of 2.5 ml / h to carry out the precipitation reaction. At the same time, apply ultrasonic waves with a power of 750 W. When the reaction temperature rises, use circulating water to replace the medium water in the ultrasonic device, and control the reaction temperature to about 30 °C; the volume ratio of the final reaction copper acetate alcohol solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com