A kind of preparation method of sodium ion battery cathode material na3v2(po4)3

A sodium-ion battery and positive electrode material technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effects of shallow embedding depth, high capacity charge and discharge, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of sodium ion battery cathode material Na 3 V 2 (PO 4 ) 3 The preparation method, this method comprises the following steps:

[0025] (1) Mix sodium salt, vanadium salt, phosphate, complexing agent, polymer compound and solvent to obtain Na 3 V 2 (PO 4 ) 3 spinning solution;

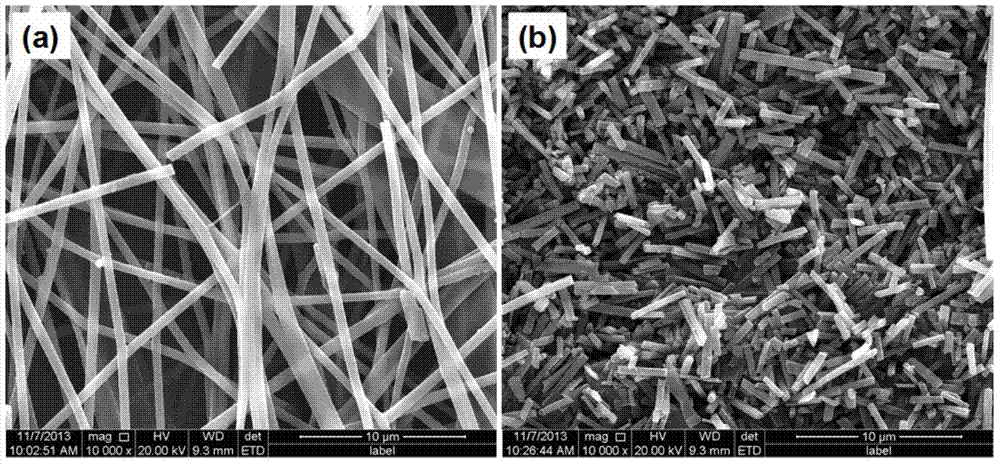

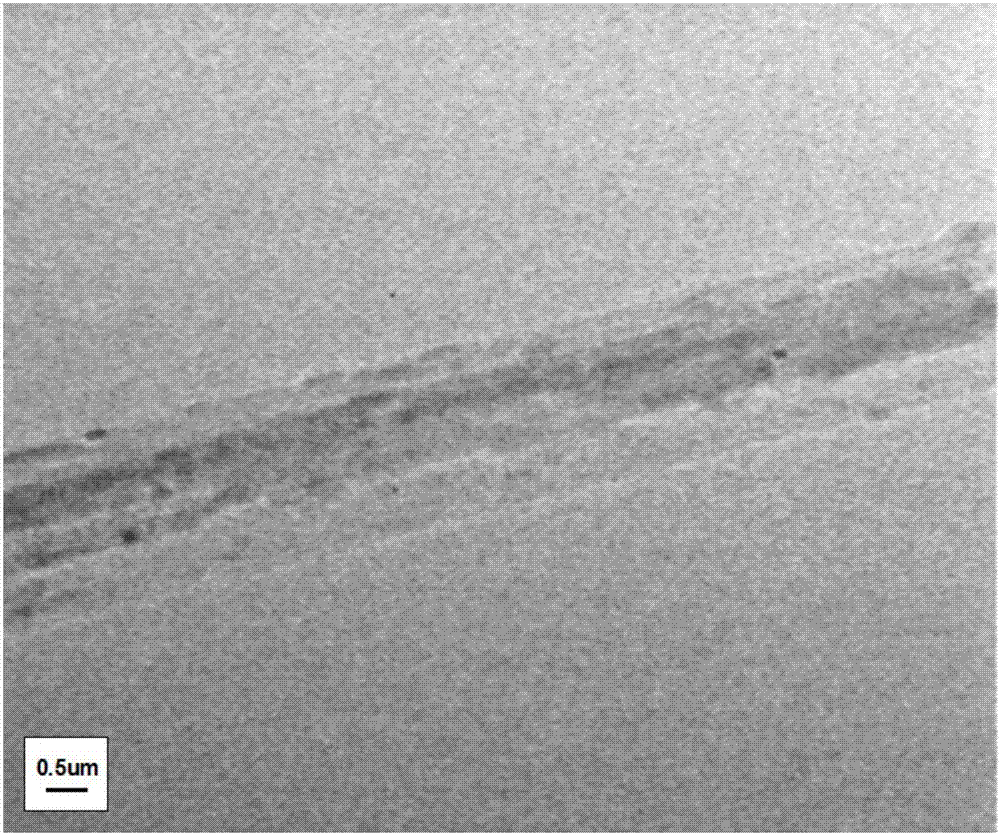

[0026] (2) Na 3 V 2 (PO 4 ) 3 The spinning solution is electrospun to obtain Na 3 V 2 (PO 4 ) 3 Spinning precursor;

[0027] (3) Collect Na 3 V 2 (PO 4 ) 3 Spinning precursor, under an inert atmosphere for Na 3 V 2 (PO 4 ) 3The spinning precursor is heat-treated, and after cooling, the anode material Na for sodium-ion batteries is obtained. 3 V 2 (PO 4 ) 3 .

[0028] In the method of the present invention, there is no special requirement for sodium salt, vanadium salt, phosphate, complexing agent, polymer compound and solvent, can be various sodium salts, vanadium salt, phosphate, complexing agent, Polymer compounds and solvents. In order...

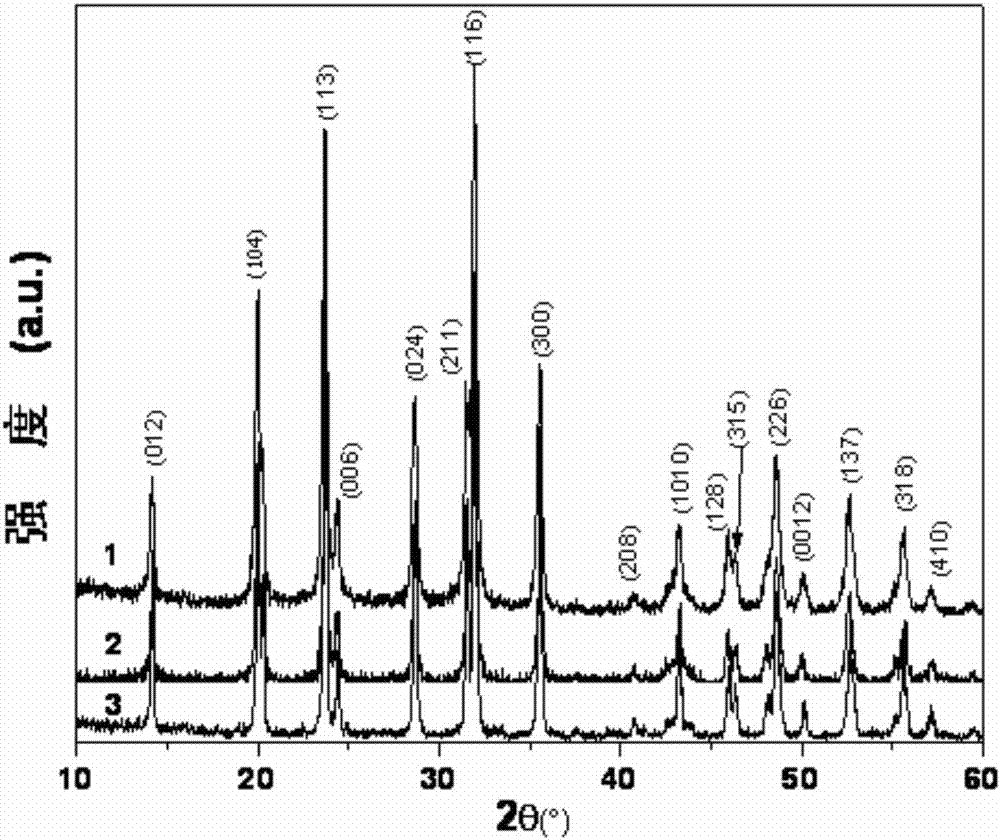

Embodiment 1

[0046] This embodiment is used to illustrate the sodium ion battery cathode material Na of the present invention 3 V 2 (PO 4 ) 3 method of preparation.

[0047] According to the ratio of substances n(Na):n(V):n(PO 4 3- ):n (citric acid)=3.2:2:3:3 Take by weighing 0.64g sodium hydroxide, 1.1698g ammonium metavanadate, 1.7254g ammonium dihydrogen phosphate and 2.8821g citric acid respectively, and dissolve into 10ml, 40ml respectively , 10ml, 10ml of deionized water, stirred at 70°C at a stirring speed of 500rpm for 1.5h until completely dissolved. Pour the sodium hydroxide solution, ammonium metavanadate solution, and ammonium dihydrogen phosphate solution into the citric acid solution, and stir at 80°C for 1.5h at a stirring speed of 500rpm to form a dark blue solution. Weigh 2 g of polyvinylpyrrolidone with an average molecular weight of 1,300,000 and dissolve it in 20 ml of deionized water, and stir at 25° C. at a stirring speed of 500 rpm for 6 h until completely diss...

Embodiment 2

[0053] This embodiment is used to illustrate the sodium ion battery cathode material Na of the present invention 3 V 2 (PO 4 ) 3 method of preparation.

[0054] Take by weighing 2.4176g sodium dihydrogen phosphate, 0.91g vanadium pentoxide and 0.9004g oxalic acid respectively by the amount ratio n (Na): n (V): n (oxalic acid)=3.1:2:2, and dissolve respectively 10ml, 40ml, and 10ml of deionized water were stirred at 60°C at a stirring speed of 400rpm for 2h until completely dissolved. Pour the sodium dihydrogen phosphate solution and the vanadium pentoxide solution into the oxalic acid solution, and stir at 60°C for 2 hours at a stirring speed of 400rpm to form a dark blue solution. Weigh 2g of polyethylene oxide with an average molecular weight of 600,000 and dissolve it in 20ml of deionized water, stir at 30°C at a stirring speed of 400rpm for 8h until completely dissolved. Add the above dark blue solution dropwise to the completely dissolved polyethylene oxide solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com