A kind of positive electrode material and preparation method thereof, positive electrode coating material and lithium ion battery

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of low utilization rate of materials, complicated preparation process, serious material agglomeration, etc. The effect of embedding, simple preparation method and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) According to the amount of substance ratio n(Fe 3+ ):n(F - )=1:4 Weigh 2.8280g Fe(NO 3 ) 3 ﹒ 9H 2 O, 0.7986gNH 4 HF 2 Add 70ml of absolute ethanol to a polytetrafluoroethylene beaker, and stir at room temperature at 500rpm for 12h until the solution turns milky white.

[0070] (2) Transfer the above-mentioned milky white solution to a 100ml polytetrafluoroethylene reaction liner, put it into a steel jacket of a hydrothermal kettle for sealing, and then put it in an oven for solvothermal reaction at 100°C for 12h.

[0071] (3) After cooling down to room temperature, the precipitate in the reactor was vacuum filtered, washed with absolute ethanol, and then dried to obtain the positive electrode material powder, which was designated as I1.

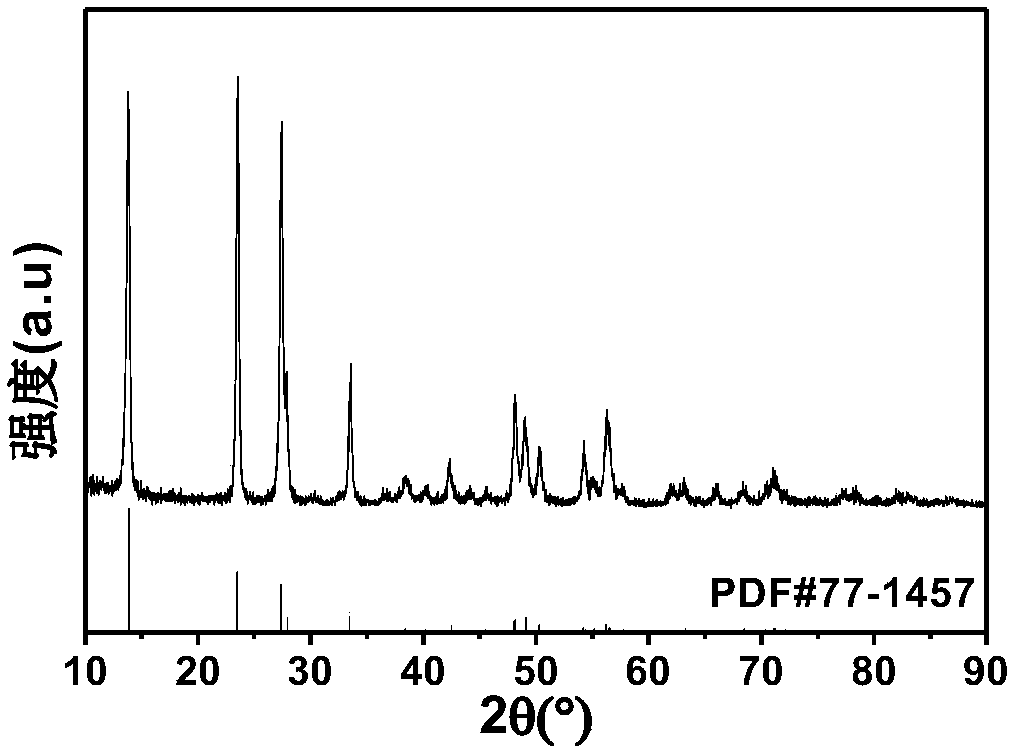

[0072] Carry out X-ray powder diffraction test to the cathode material powder that embodiment 1 prepares, and XRD collection of patterns is as follows figure 1 shown, compared to NH 4 FeF 4 The standard card shows that th...

Embodiment 2

[0075] (1) According to the amount of substance ratio n(Fe 3+ ):n(F - )=1:3.9 Weigh 2.8280g Fe(NO 3 ) 3 ﹒ 9H 2 O, 0.7786g NH 4 HF 2 Add 65ml of absolute ethanol to a polytetrafluoroethylene beaker, and stir at 600rpm at room temperature for 10h until the solution turns milky white.

[0076] (2) Transfer the above-mentioned milky white solution to a 100ml polytetrafluoroethylene reaction liner, put it into a steel sleeve of a hydrothermal kettle for sealing, and then put it in an oven for solvothermal reaction at 120°C for 13h.

[0077] (3) After cooling down to room temperature, the precipitate in the reaction kettle was vacuum filtered, washed with absolute ethanol, and then dried to obtain the positive electrode material powder, which was denoted as I2.

[0078] Carry out X-ray powder diffraction test to the cathode material powder that embodiment 2 prepares, obtain and figure 1 The same XRD pattern.

Embodiment 3

[0080] (1) According to the amount of substance ratio n(Fe 3+ ):n(F - )=1:4.1 Weigh 2.164g FeCl respectively 3 ·6H 2 O, 1.2136gNH 4 F Add 70ml of absolute ethanol to a polytetrafluoroethylene beaker, stir at 400rpm at room temperature for 14h until the solution turns milky white.

[0081] (2) Transfer the above-mentioned milky white solution to a 100ml polytetrafluoroethylene reaction liner, put it into a steel jacket of a hydrothermal kettle for sealing, and then put it in an oven for solvothermal reaction at 140°C for 11 hours.

[0082] (3) After cooling down to room temperature, centrifuge the precipitate in the reaction kettle at a speed of 4000 rpm, wash with absolute ethanol, and then dry the precipitate to obtain the positive electrode material powder, which is denoted as I3.

[0083] Carry out X-ray powder diffraction test to the cathode material powder that embodiment 3 prepares, obtain and figure 1 The same XRD pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com