A kind of positive electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery and positive electrode material technology, applied in the field of lithium-ion battery positive electrode materials and their preparation, can solve the problems affecting the final shape of the material, high cost, etc., and achieve the benefits of ion transmission, fewer influencing factors, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

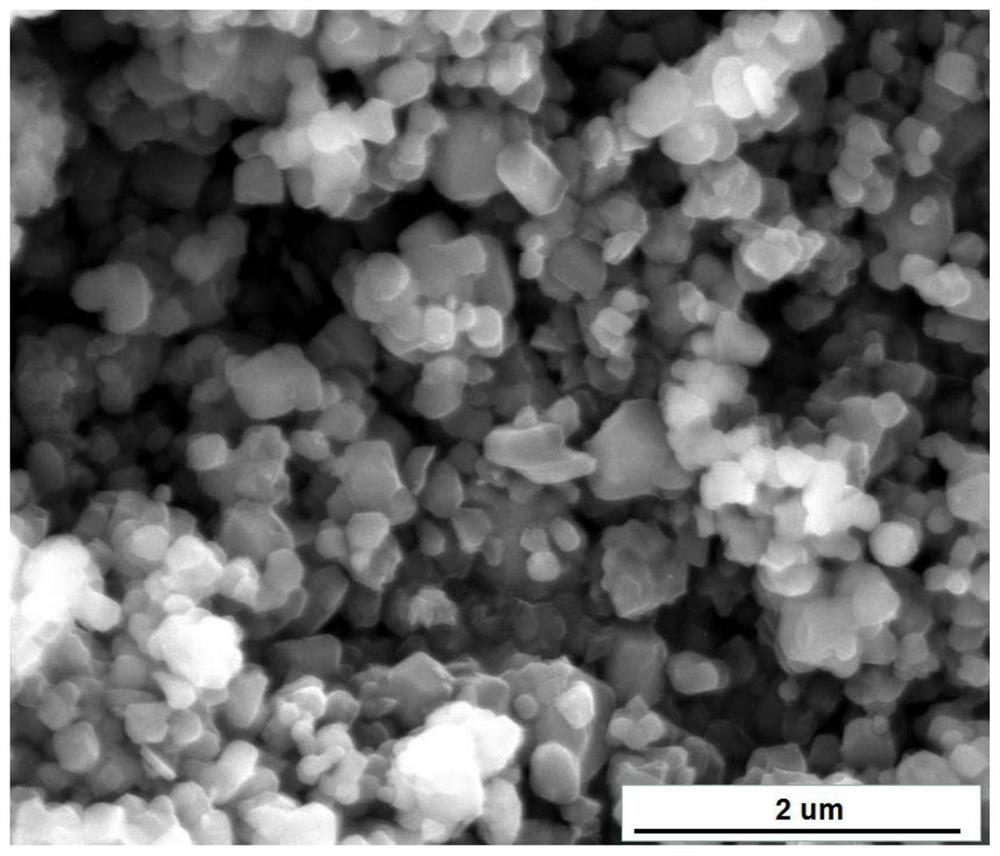

[0041] A kind of Li 2 MnSiO 4 The preparation method of / C cathode material specifically comprises the following steps:

[0042] S1, add 0.038mol of oleic acid into 50ml of ethanol solution, stir magnetically at 50°C to form a uniform transparent solution, then add 0.019mol of lithium hydroxide monohydrate, continue magnetic stirring until lithium hydroxide monohydrate is completely dissolved and A white mixed solution is formed, which is the first solution;

[0043] S2, dissolving 0.01mol manganese acetate tetrahydrate and 0.01mol ethyl orthosilicate in ethanol to form a second solution;

[0044] S3, adding the second solution to the first solution, and stirring at 50° C. for 2 hours to obtain a mixed gel;

[0045]S4, put the mixed gel in an oven at 50°C for 10 hours and grind it into a 100-mesh powder; place the fine powder in a tube furnace with an argon atmosphere, and raise the temperature from 20°C to After pre-calcining at 300°C for 5 hours, then heating up to 900°C...

Embodiment 2

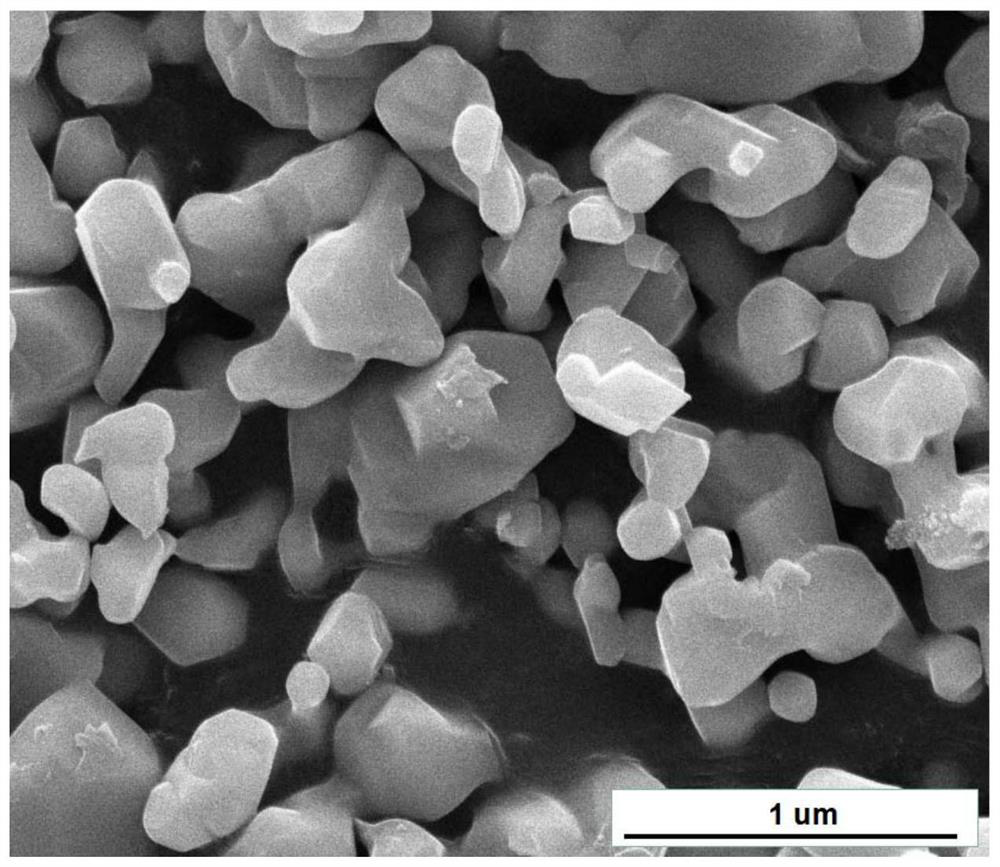

[0047] A kind of Li 2 MnSiO 4 The preparation method of / C cathode material specifically comprises the following steps:

[0048] S1, add 0.032mol of oleic acid into 50ml of ethylene glycol solution, stir magnetically at 60°C to form a uniform transparent solution, then add 0.01mol of lithium oxalate, continue magnetic stirring until the lithium oxalate is completely dissolved and a white mixed solution is formed , which is the first solution;

[0049] S2, dissolving 0.01mol manganese oxalate and 0.01mol methyl orthosilicate in ethylene glycol to form a second solution;

[0050] S3, adding the second solution to the first solution, stirring at 60° C. for 1.5 h to obtain a mixed gel;

[0051] S4, the mixed gel was dried in an oven at 60°C for 9 hours and then ground into powder; the powder was placed in a tube furnace with an argon atmosphere, and the temperature was raised from 20°C to 400°C at a heating rate of 5°C / min. After firing for 3 hours, the temperature was raised ...

Embodiment 3

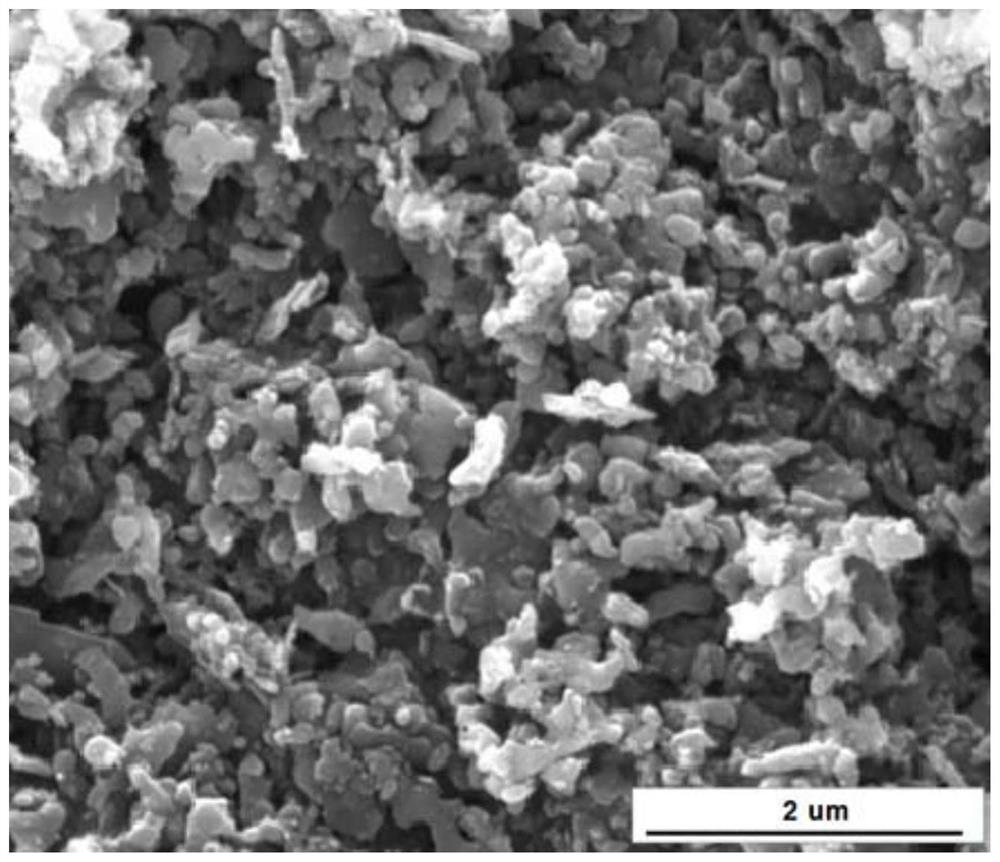

[0053] A kind of Li 2 MnSiO 4 The preparation method of / C cathode material specifically comprises the following steps:

[0054] S1, add 0.0168mol of oleic acid into 50ml of acetone solution, magnetically stir at 70°C to form a uniform transparent solution, then add 0.007mol of lithium citrate, continue magnetically stirring until the lithium citrate is completely dissolved and a white mixed solution is formed, is the first solution;

[0055] S2, dissolving 0.01mol of manganese nitrate and 0.01mmol of propyl orthosilicate in acetone to form a second solution;

[0056] S3, adding the second solution to the first solution, and stirring at 70° C. for 1.5 h to obtain a mixed gel;

[0057] S4, the mixed gel was dried in an oven at 100°C for 1 hour and then ground into powder; the powder was placed in a tube furnace with an argon atmosphere, and the temperature was raised from 20°C to 500°C at a heating rate of 5°C / min After pre-calcining for 2 hours, heat up to 700°C at a heati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com