Preparation method of zinc oxide nanoparticle lithium ion battery negative electrode material with high specific capacity

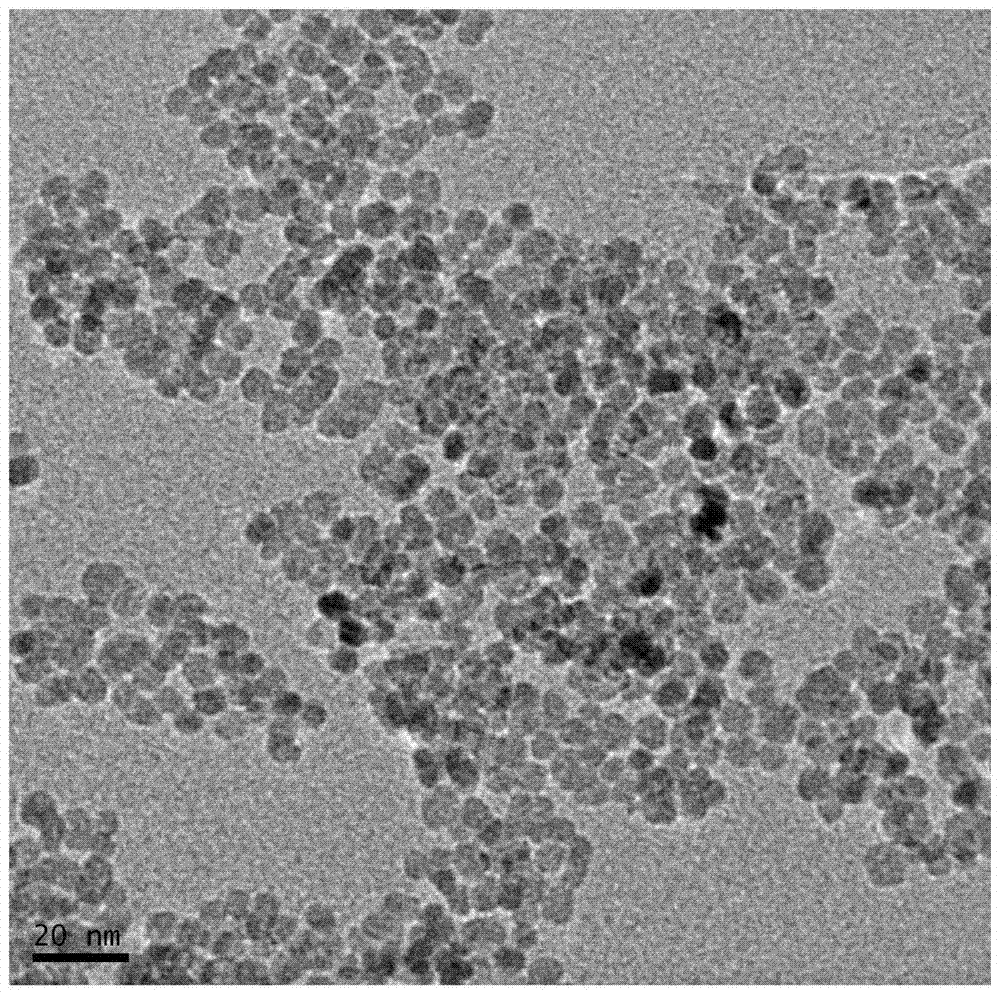

A zinc oxide nano, lithium ion battery technology, applied in battery electrodes, zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, etc. The effect of learning, short diffusion path and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

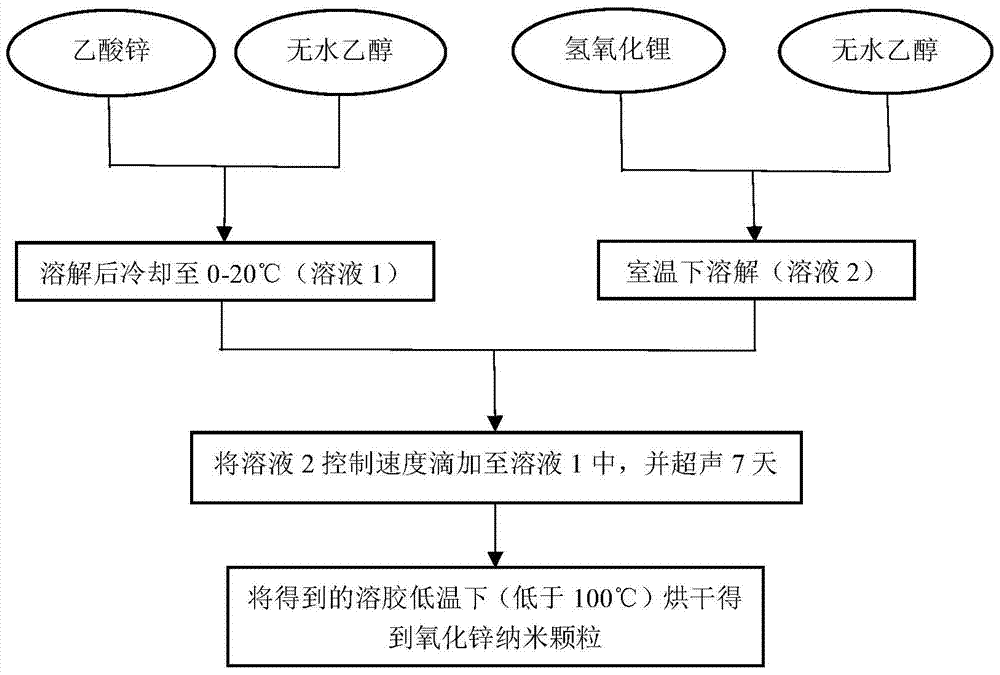

Method used

Image

Examples

Embodiment 1

[0032] 1) Put 13mmol of zinc acetate in 130mL of absolute ethanol, and heat to dissolve at 50°C under magnetic stirring;

[0033] 2) When the zinc acetate is completely dissolved, add absolute ethanol to keep the volume of the solution at 130mL, and cool to 10°C;

[0034] 3) 10 mmol of crystalline lithium hydroxide was dissolved in 130 mL of absolute ethanol at room temperature by magnetic stirring;

[0035] 4) The lithium hydroxide solution obtained in step 3) is added dropwise to the solution of step 2) under stirring, and the dropwise addition is completed in 20 minutes;

[0036] 5) At room temperature, ultrasonically disperse the above mixed solution for 4 days to obtain a white sol;

[0037] 6) centrifuging and cleaning the obtained sol;

[0038] 7) put it into a drying oven, and dry at 60° C. for 24 hours to obtain zinc oxide nanoparticles, that is, zinc oxide nanoparticles lithium ion battery negative electrode material with high specific capacity.

[0039] The prepa...

Embodiment 2

[0044] 1) Put 15mmol of zinc acetate in 100mL of absolute ethanol, and heat to dissolve at 40°C under magnetic stirring;

[0045] 2) When the zinc acetate is completely dissolved, re-dilute to 100mL with absolute ethanol and cool to 10°C;

[0046] 3) 11.5 mmol of crystalline lithium hydroxide was dissolved in 150 mL of absolute ethanol at room temperature by magnetic stirring;

[0047] 4) The lithium hydroxide solution obtained in step 3) was added dropwise to the solution of step 2) under stirring, and the addition was completed in 25 minutes;

[0048] 5) ultrasonically sonicate the above mixed solution for 7 days at room temperature to obtain a white sol;

[0049] 6) centrifuging and cleaning the obtained sol;

[0050] 7) put it into a drying oven, and dry at 60° C. for 24 hours to obtain zinc oxide nanoparticles, that is, zinc oxide nanoparticles lithium ion battery negative electrode material with high specific capacity.

Embodiment 3

[0052] 1) Put 18mmol of zinc acetate in 90mL of absolute ethanol, and heat to dissolve at 75°C under magnetic stirring;

[0053] 2) When zinc acetate is completely dissolved, re-dilute to 90mL with absolute ethanol and cool to 0°C;

[0054] 3) 13.8 mmol of crystalline lithium hydroxide was dissolved in 150 mL of absolute ethanol at room temperature by magnetic stirring;

[0055] 4) The lithium hydroxide solution obtained in step 3) was added dropwise to the solution of step 2) under stirring, and the addition was completed in 25 minutes;

[0056] 5) ultrasonically sonicate the above mixed solution for 4 days at room temperature to obtain a white sol;

[0057] 6) centrifuging and cleaning the obtained sol;

[0058] 7) put it into a drying oven, and dry at 60° C. for 24 hours to obtain zinc oxide nanoparticles, that is, zinc oxide nanoparticles lithium ion battery negative electrode material with high specific capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com