Novel surface carbon modified layered lithium-rich ternary positive electrode composite material and preparation method thereof

A lithium-rich material and layered technology, which is applied in the field of layered ternary lithium-rich materials, can solve the problems of poor structural stability of composite materials, restrictions on large-scale commercial applications, and poor conductivity of lithium-rich materials. Suppression of the Jahn-Teller effect, small diameter, and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

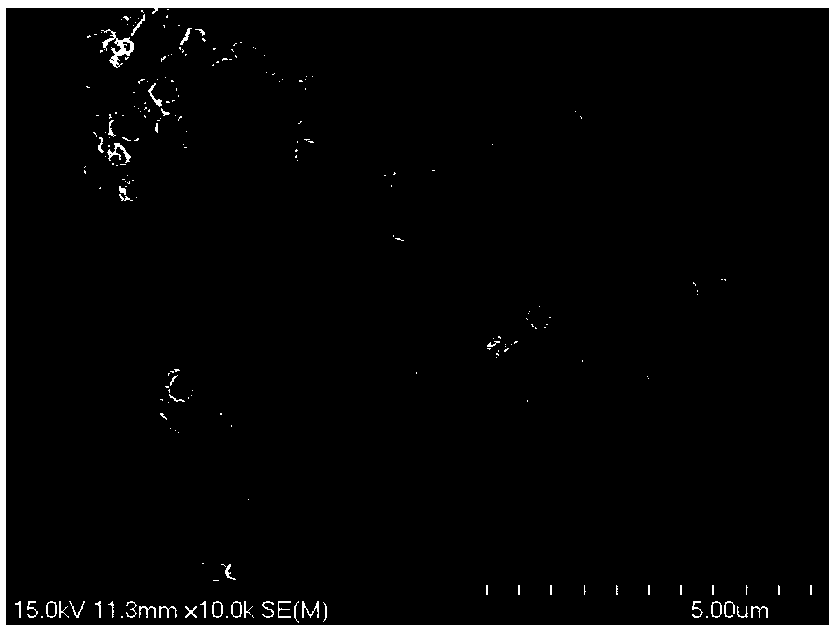

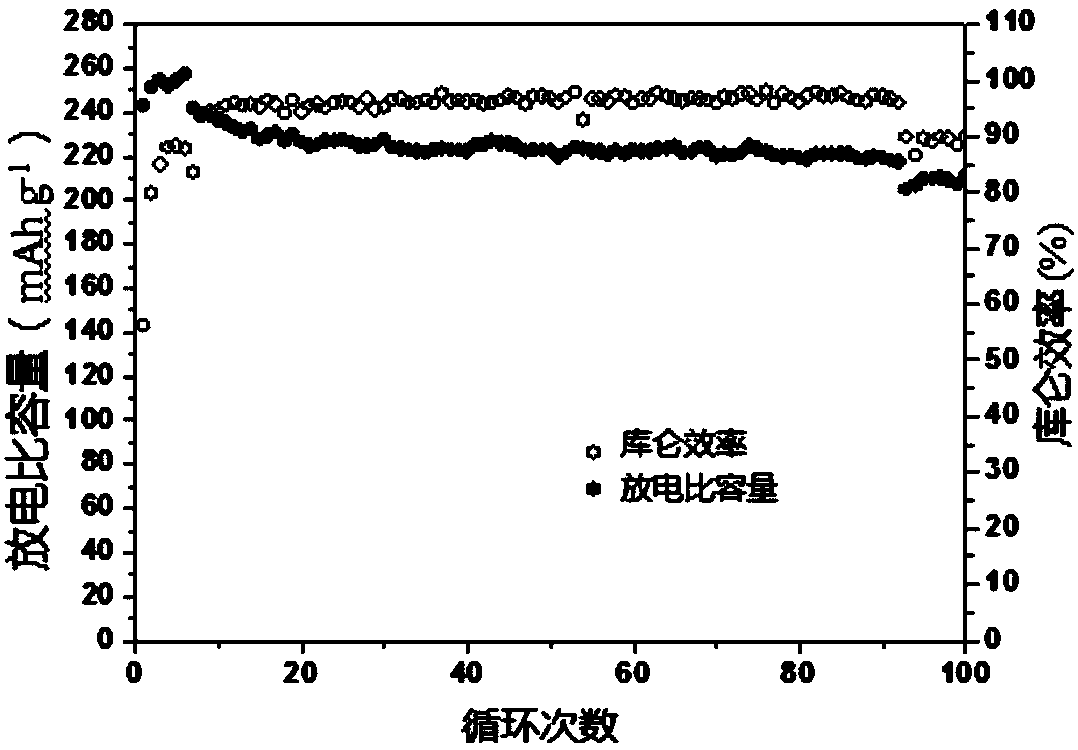

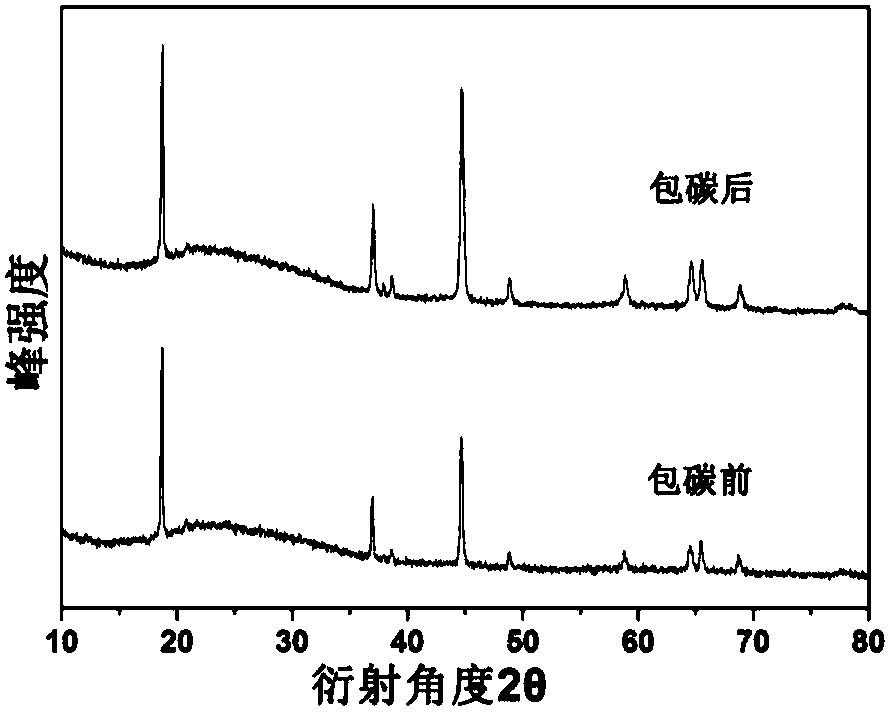

[0038] KMnO 4 Mix evenly with glucose according to the substance ratio of 5:1, put it into a high-pressure reactor, stir for 15 minutes, and continue to ultrasonically vibrate for 120 minutes. Put it into a blast for hydrothermal reaction, the reaction time is 5h, and the temperature is 170°C. Pour out the reaction solution, centrifuge, discard the supernatant, wash the remaining solid with ethanol and aqueous solution and centrifuge several times, discard the supernatant, and dry at 40°C to obtain β-MnO 2 , the resulting 0.55g β-MnO 2 As the manganese source, nickel nitrate, cobalt nitrate and lithium carbonate were respectively used as the nickel source, and the ratio of the cobalt source and the lithium source was based on the molar ratio of the contained metal elements, specifically 4:1:1:9.2, and ball milled for 4 hours. The ground powder was calcined in an air atmosphere at a temperature of 800 °C for 8 h to obtain 0.5 Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 com...

Embodiment 2

[0041] KMnO 4 Mix evenly with glucose according to the substance ratio of 7:1, put it into a high-pressure reactor, stir for 60 minutes, and continue to ultrasonically shake for 30 minutes. Put it into a blast for hydrothermal reaction, the reaction time is 3 hours, and the temperature is 190°C. Pour out the reaction solution, centrifuge, discard the supernatant, wash the remaining solid with ethanol and aqueous solution and centrifuge several times, discard the supernatant, and dry at 70°C to obtain β-MnO 2 , the resulting 0.6g β-MnO 2 As the manganese source, nickel acetate, cobalt acetate and lithium hydroxide were used as nickel source respectively, and the ratio of cobalt source and lithium source was based on the molar ratio of the contained metal elements, specifically 3.9:1:1:10.4, and ball milled for 6 hours. The ground powder was calcined in an air atmosphere at a temperature of 700 °C for 12 h to obtain 0.5 Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 . 0.05g...

Embodiment 3

[0044] KMnO 4 Mix evenly with glucose according to the substance ratio of 7:1, put it into a high-pressure reactor, stir for 50 minutes, and continue to ultrasonically shake for 30 minutes. Put it into a blast for hydrothermal reaction, the reaction time is 3 hours, and the temperature is 200°C. Pour out the reaction solution, centrifuge, discard the supernatant, wash the remaining solid with ethanol and aqueous solution and centrifuge several times, discard the supernatant, and dry at 70°C to obtain β-MnO 2 , the resulting 0.585g β-MnO 2 As the manganese source, nickel sulfate, cobalt sulfate and lithium carbonate were respectively used as nickel source, cobalt source and lithium source, and the ratio was based on the molar ratio of the contained metal elements, specifically 4:1:1:9.8, and ball milled for 5 hours. The ground powder was calcined in an air atmosphere at a temperature of 850 °C for 11 h to obtain 0.5 Li 2 MnO 3 0.5LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 . 0.05g gluc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com