Composite nano material and preparation method and application thereof

A technology of composite nanomaterials and nanotubes, applied in nanocarbon, carbon nanotubes, nanotechnology and other directions, can solve the problems of unsatisfactory electrical performance indicators such as capacitance and cycle performance of negative electrode materials, and achieve good cycle performance and enhanced diffusion. The effect of speed, good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of composite nano material, concrete steps are as follows:

[0033] (1) First use acidified carbon nanotubes as raw materials, and use polyethyleneimine to modify them to prepare modified carbon nanotubes;

[0034] (2) Then react the modified carbon nanotubes with epoxidized cellulose to form carbon nanotube-cellulose composites;

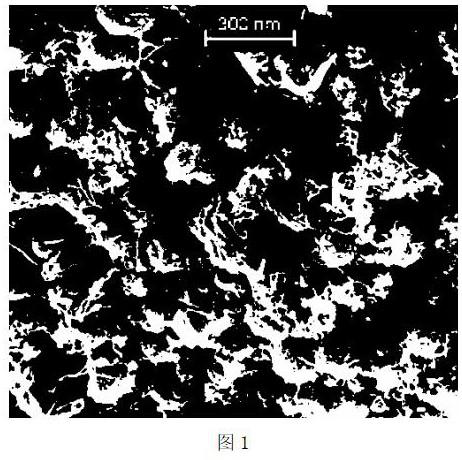

[0035] (3) Finally, the carbon nanotube-cellulose composite is doped with nitrogen, phosphorus, and copper in sequence to obtain the composite nanomaterial (see the SEM image in figure 1 ).

[0036] The specific method of step (1) is: first disperse 1kg of acidified carbon nanotubes in 8kg of water, then add 100kg of polyethyleneimine, 500W ultrasonic vibration for 40 minutes, and then vigorously stir at a stirring rate of 8000r / min for 30 minutes, using mass Adjust the pH to 8 with concentrated ammonia water at a concentration of 25%, centrifuge, wash with deionized water three times, and dry in vacuum to obtai...

Embodiment 2

[0045] A kind of preparation method of composite nano material, concrete steps are as follows:

[0046] (1) First use acidified carbon nanotubes as raw materials, and use polyethyleneimine to modify them to prepare modified carbon nanotubes;

[0047] (2) Then react the modified carbon nanotubes with epoxidized cellulose to form carbon nanotube-cellulose composites;

[0048] (3) Finally, the carbon nanotube-cellulose composite is sequentially doped with nitrogen, phosphorus, and copper to obtain the composite nanomaterial.

[0049] The specific method of step (1) is: first disperse 1kg of acidified carbon nanotubes in 10kg of water, then add 80kg of polyethyleneimine, 700W ultrasonic vibration for 30 minutes, and then vigorously stir at a stirring rate of 10000r / min for 20 minutes, using mass Concentrated ammonia water with a concentration of 28% adjusted the pH to 7, centrifuged, washed with deionized water for 4 times, and dried in vacuum to obtain the modified carbon nanotu...

Embodiment 3

[0058] A kind of preparation method of composite nano material, concrete steps are as follows:

[0059] (1) First use acidified carbon nanotubes as raw materials, and use polyethyleneimine to modify them to prepare modified carbon nanotubes;

[0060] (2) Then react the modified carbon nanotubes with epoxidized cellulose to form carbon nanotube-cellulose composites;

[0061] (3) Finally, the carbon nanotube-cellulose composite is sequentially doped with nitrogen, phosphorus, and copper to obtain the composite nanomaterial.

[0062] The specific method of step (1) is: first disperse 1kg of acidified carbon nanotubes in 9kg of water, then add 90kg of polyethyleneimine, 600W ultrasonic vibration for 35 minutes, and then vigorously stir at a stirring rate of 9000r / min for 25 minutes. Concentrated ammonia water with a concentration of 26% adjusted the pH to 7, centrifuged, washed with deionized water 4 times, and dried in vacuum to obtain the modified carbon nanotubes.

[0063] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com