Ceramic sanitary ceramic green body and preparation method thereof

A technology of sanitary ceramics and body, applied in the field of ceramic sanitary ceramic body and its preparation, can solve problems such as limited use, environmental problems, insufficient strength, etc., reduce deformation, improve pass rate and manufacturing precision, and improve firing rate. into the effect of flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

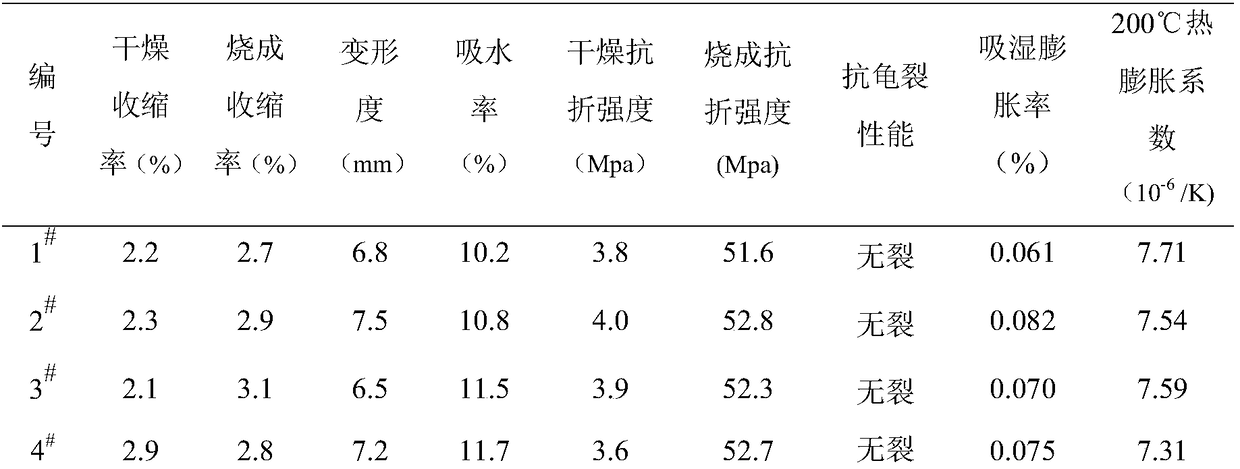

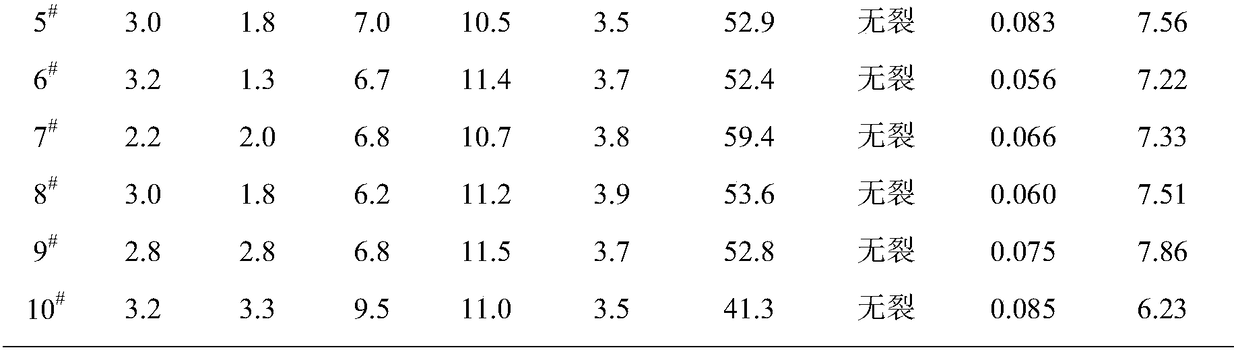

Examples

preparation example Construction

[0040] Another aspect of the present invention provides a method for preparing the ceramic sanitary ceramic body, comprising the following steps:

[0041] (1) Making mud: Weigh the raw materials of each billet according to the above formula, add boron nitride micropowder in the formula, add water glass as a debonding agent, add water and mix, stir evenly and use ball milling, after sieving and iron removal Prepared as slurry for grouting;

[0042] (2) Squeeze the mud: inject the mud into the gypsum mold to press the mud;

[0043] (3) Drying: dry the mud base after stripping to obtain the initial base;

[0044] (4) Firing: firing the blank in the kiln.

[0045] In a specific embodiment, the performance requirements of the mud: mud concentration 346~370g / 200ml, 350 mesh sieve residue is 6%~10%, particle size (0 50~60s, V 30 110~130s, slurry suction speed 5~7mm / 45min.

[0046] In a specific embodiment, the drying method is: firstly drying at 25-50° C. for 12 hours, and then...

Embodiment 1

[0050] The ceramic green body provided in this embodiment includes a blank and auxiliary agents, and the blank includes the following components in weight percentage: 20% of southern black mud, 8% of southern kaolin, 11% of waste porcelain powder, 8% of blast furnace slag, and 15% of southern pyrophyllite , 3% talc, 10% calcined kaolin, 5% dolomite, 15% quartz and 5% wollastonite; the auxiliary agent is boron nitride micropowder, and its usage is 0.5% of the mass of the billet.

[0051] The chemical composition of the ceramic blank is SiO 2 59.4%, Al 2 o 3 20.2%, Fe 2 o 3 1.2%, TiO 2 0.26%, CaO 6.8%, MgO 3.2%, K 2 O 1.1%, Na 2 O 0.2% and loss on ignition 7.27%.

[0052] The preparation method of above-mentioned ceramic green body is as follows:

[0053] (1) Make mud: weigh each blank according to the above formula, add boron nitride micropowder in the formula, add water glass as a debonding agent, add water, stir in a mixer and put it into a ball mill for ball mill...

Embodiment 2

[0057] The ceramic green body provided in this embodiment includes a blank and auxiliary agents, and the blank includes the following components in weight percentage: 10% of southern black mud, 5% of southern kaolin, 8% of waste porcelain powder, 10% of blast furnace slag, and 20% of southern pyrophyllite , 5% talc, 15% calcined kaolin, 1% dolomite, 20% quartz and 6% wollastonite; the auxiliary agent is boron nitride powder, and its usage is 0.2% of the mass of the billet.

[0058] The chemical composition of the ceramic blank is SiO 2 63.9%, Al 2 o 3 19.4%, Fe 2 o 3 0.97%, TiO 2 0.21%, CaO 6.74%, MgO 3.20%, K 2 O 0.92%, Na 2 O 0.19% and loss on ignition 4.13%.

[0059] The preparation method of above-mentioned ceramic green body is as follows:

[0060] (1) Make mud: weigh each blank according to the above formula, add boron nitride micro-powder in the formula, add water glass as a debonding agent, add water, stir in a mixer and then put it into a ball mill for ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com