Method for calculating volume of internal void of microcapsule based on solute volatilization system

A technology of void volume and calculation method, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve the problems of moisture loss, long drying time, shrinkage and degeneration of microcapsules, etc., to achieve easy operation. , The effect of reagent configuration is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the iodine water is as follows: Weigh 0.0953-0.1588g iodine element and 2.5g potassium iodide, dilute to 1L with 30% ethanol, and dilute 5 times after preparation to obtain 0.15-0.25mmol / L iodine aqueous solution.

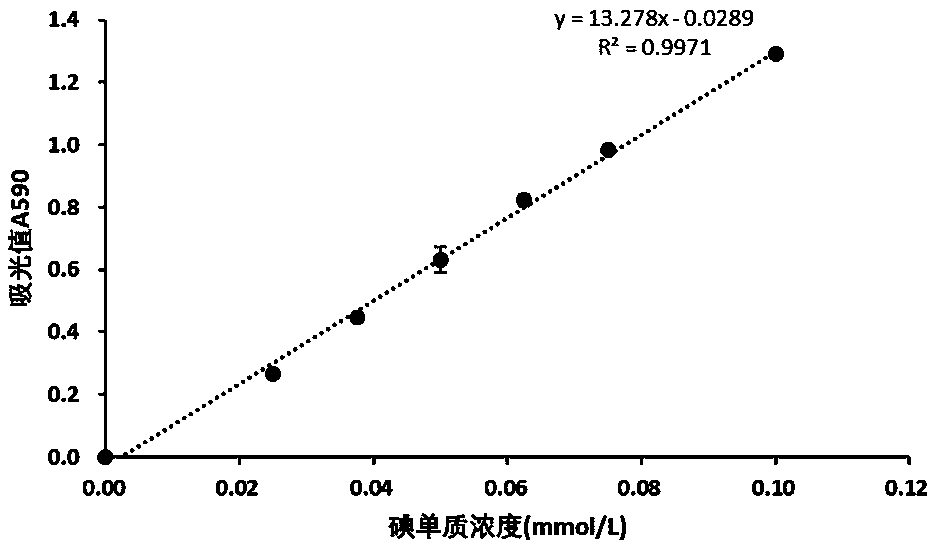

[0022] The determination method of the iodine elemental concentration is: take 1mL of iodine water to be tested, add 0.4mL of 1ωt% soluble starch solution, dilute to 10mL with deionized water, oscillate and mix for color development, and measure the absorbance value at 590nm after color development , calculate the concentration of elemental iodine in the iodine water to be tested according to the iodine concentration standard curve.

[0023] The calculation method of the internal void volume of the microcapsule is: a part of iodine elemental substance in the iodine water outside the microcapsule volatilizes in the air, and the other part enters the inside of the microcapsule, and simultaneously enters and exits the microcapsule membr...

Embodiment 1

[0027] The microcapsules used are sodium alginate microcapsules, such as:

[0028] First, by figure 1 It can be seen that there is no color reaction between sodium alginate solution and iodine element, indicating that this method is suitable for sodium alginate microcapsules.

[0029] The preparation method of sodium alginate is as follows: 3mL of 3ωt% sodium alginate is mixed with 3mL of deionized water, then dripped dropwise into 100mL of 2ωt% calcium chloride dihydrate solution with a 1mL pipette gun, and immobilized for 60min.

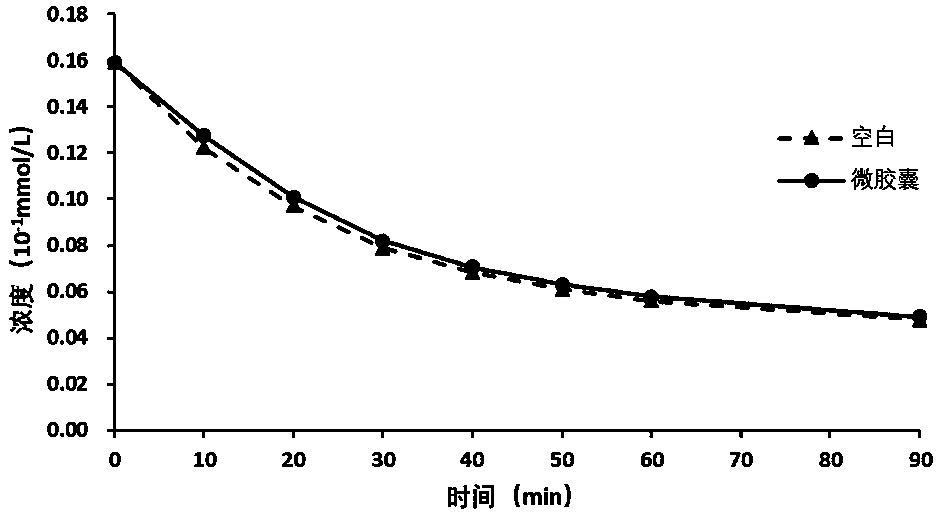

[0030] Sodium alginate microcapsules were placed in 100mL iodine water with an iodine element content of 0.16mmol / L, magnetically stirred for 90min, samples were taken at regular intervals to measure the iodine element concentration, and the volatilization curve of iodine element was drawn. As a control, the internal void volume of the microcapsules was calculated according to the mass conservation and the iodine element concentration difference b...

Embodiment 2

[0042] The microcapsules used are sodium alginate-chitosan microcapsules, and the rest of the methods remain unchanged.

[0043] The preparation method of sodium alginate-chitosan microcapsules is as follows: mix 4mL of 2.5ω% sodium alginate solution with deionized water at a ratio of 8:1, drop into 1.5ω% calcium chloride dihydrate solution, fix After 1 hour, the prepared gel beads were reacted with 0.6ω% chitosan for 15 minutes, and then treated with 0.15ω% sodium alginate solution for 5 minutes, and finally liquefied with 0.055mol / L citric acid in the capsule 30min.

[0044] The final volume in the capsule was 0.6234±0.0021mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com