Straw unbundling and spreading method and orchard straw mulching machine

A technology for covering machines and straws, which is applied to agricultural machinery and implements, soil-lifting machinery, and applications, can solve the problems of labor-intensive, time-consuming, and simple methods, and achieve the effect of promoting popularization and application, improving soil conditions, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Mechanized operation method for dismantling stalks and spreading materials in orchards

[0040] This embodiment is to carry out the mechanized operation of stalk-shaped stalk decomposing and spreading materials in an apple orchard with short stock. The distance between rows of apples on short stock in the orchard is 3.5 to 4.5 meters, and the tree shape and crown are neat.

[0041] The square-shaped wheat stalks are detached, crushed, combed and spread evenly between rows of fruit trees in a mechanized manner. The method includes the following steps:

[0042] (1) Loading: Load the straw bales into the orchard straw-covered locomotive compartment; the bottom of the compartment is equipped with a conveying and pulling device, and the rear of the compartment is equipped with an unbundling and spreading device. The space at the bottom of the discharge end at the rear of the carriage intersects to form a discharge opening, and the height of the discharge opening ...

Embodiment 2

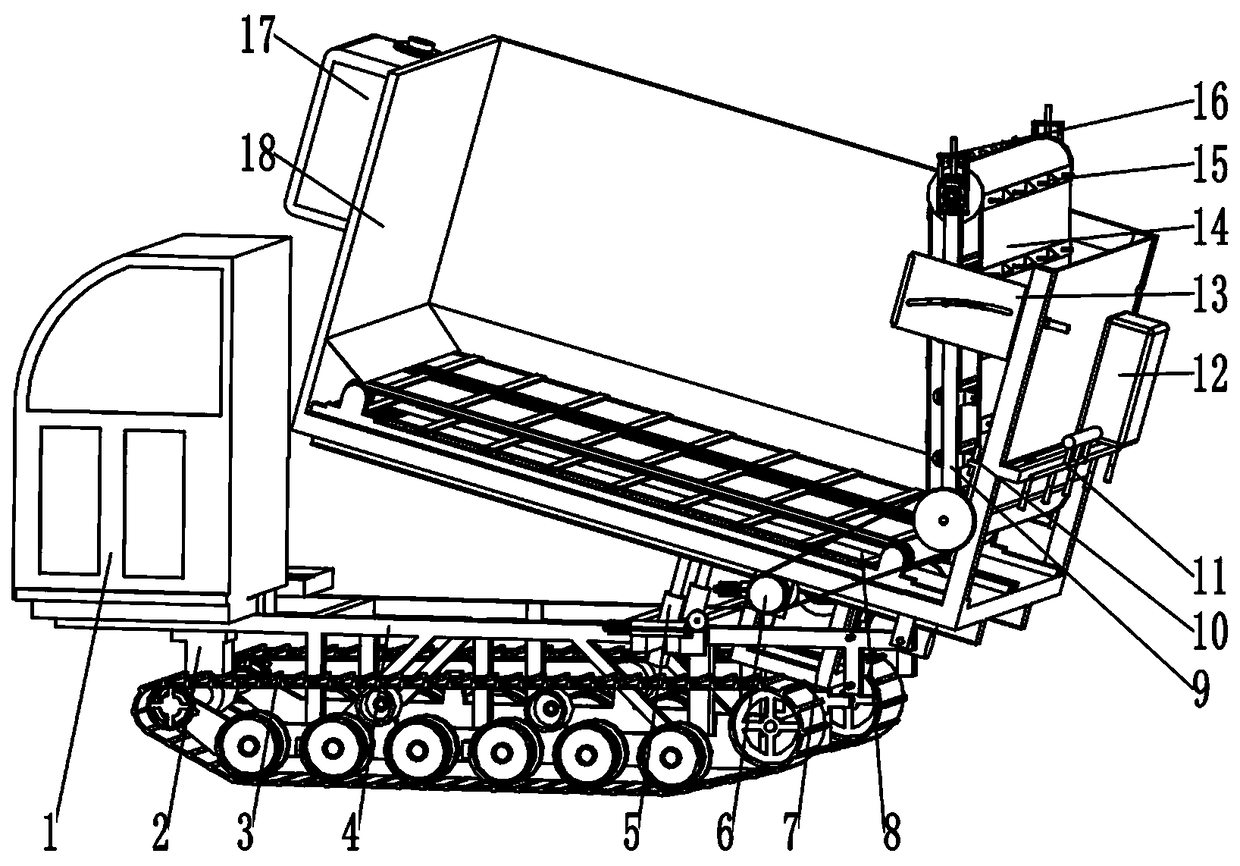

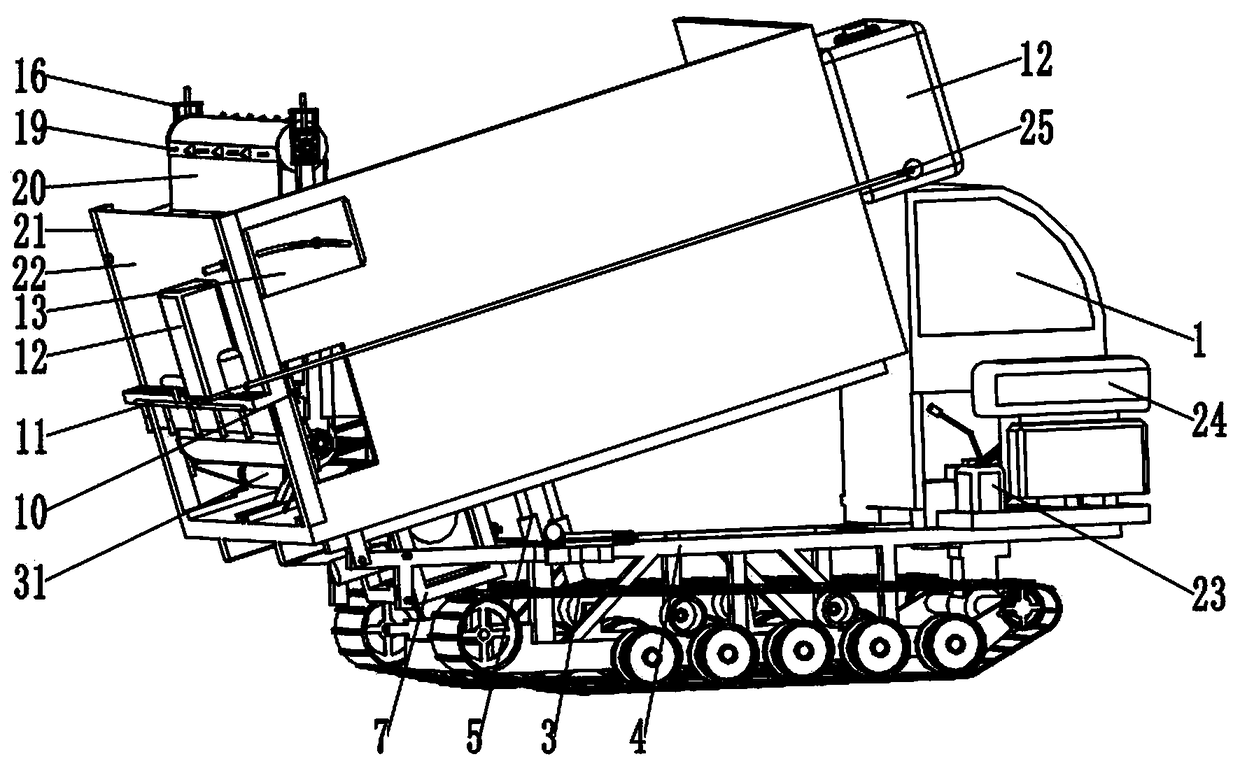

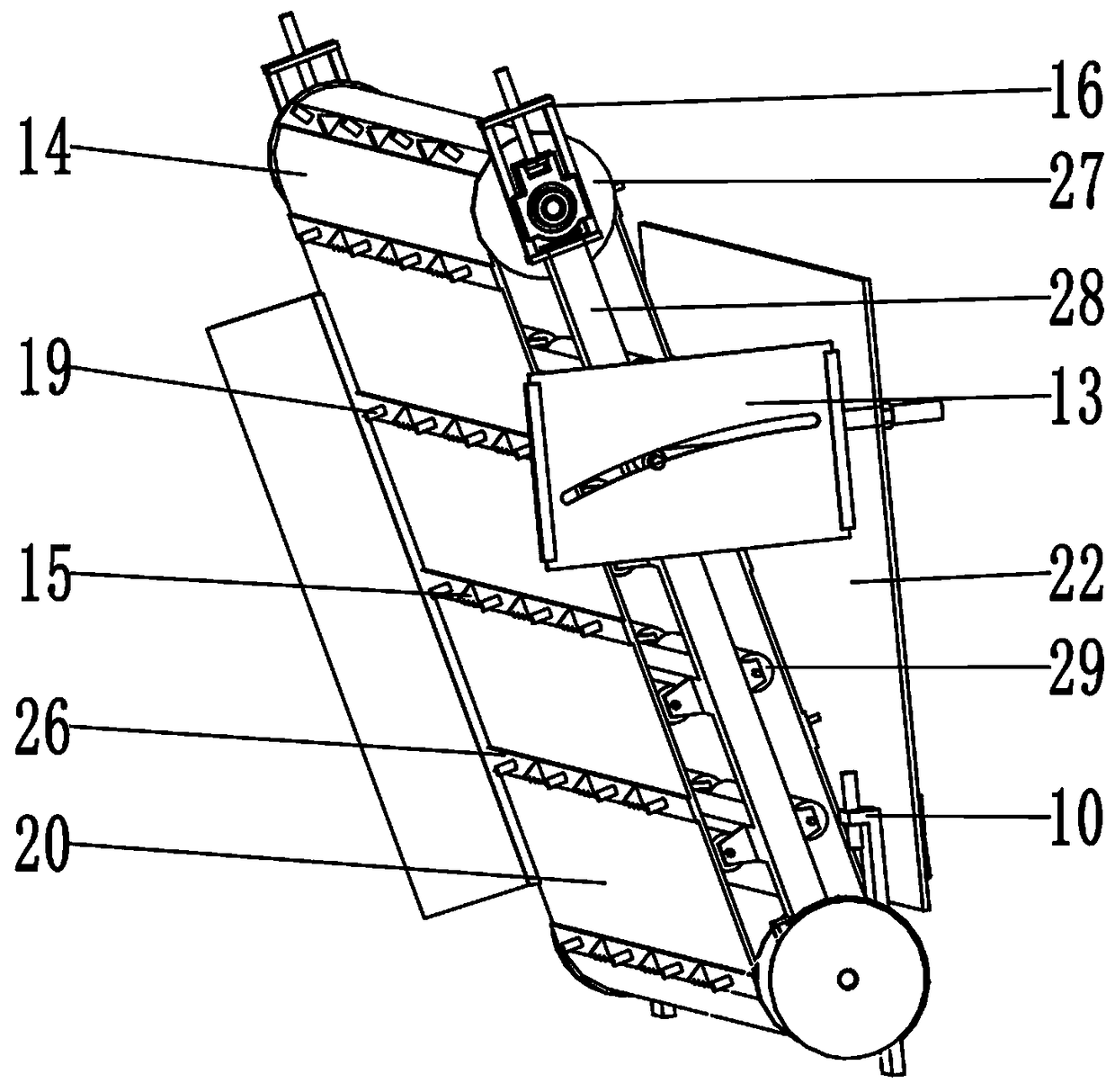

[0047] Example 2: Orchard Straw Covering Machine

[0048] Such as figure 1 and figure 2 As shown, an orchard straw covering machine is characterized in that a vehicle frame 4 is fixed above the crawler chassis 3, and a cab 1, an engine 24, a transmission box 2 and a hydraulic pump 23 are installed in front of the vehicle frame 4, and the upper part of the vehicle frame 4 A compartment 18 is installed at the rear, and the rear end bottom of the compartment 18 is hinged with the vehicle frame 4; at least one hydraulic tipping oil cylinder 5 is installed on the crossbeam of the vehicle frame 4, its lower end is hinged with the vehicle frame 4, and its upper end is hinged with the bottom of the compartment 18;

[0049] Such as figure 1 and figure 2 As shown, at least one set of conveying and pulling device 8 is installed on the inner bottom surface of the compartment 18, and a material shifting transmission device 7 is installed on the outer bottom surface of the compartment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com