Wearable garment sensor and preparation method and application thereof

A sensor and wearable technology, which is applied in the field of wearable clothing sensors and its preparation, can solve the problems of lack of human body movement and physiological signals, unfavorable fabric breathability and perspiration, and limited application range, so as to increase the application range and convenience. Effect of low resistance and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

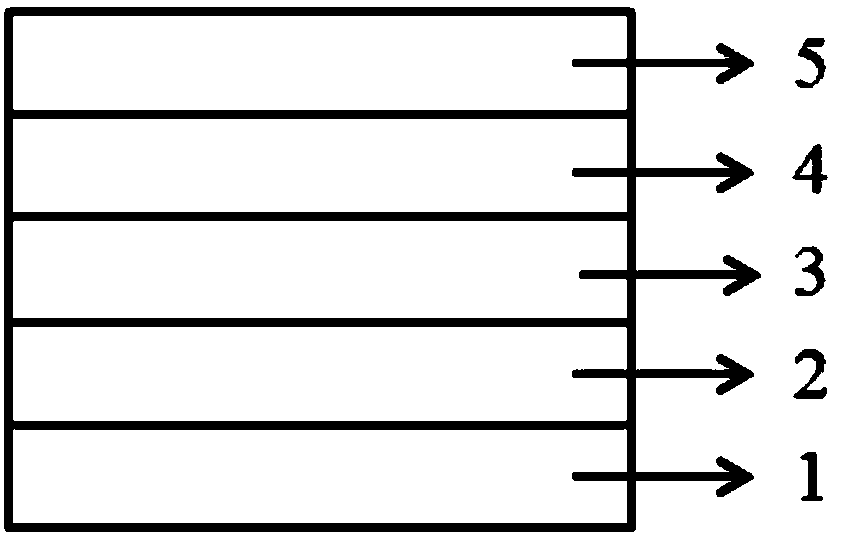

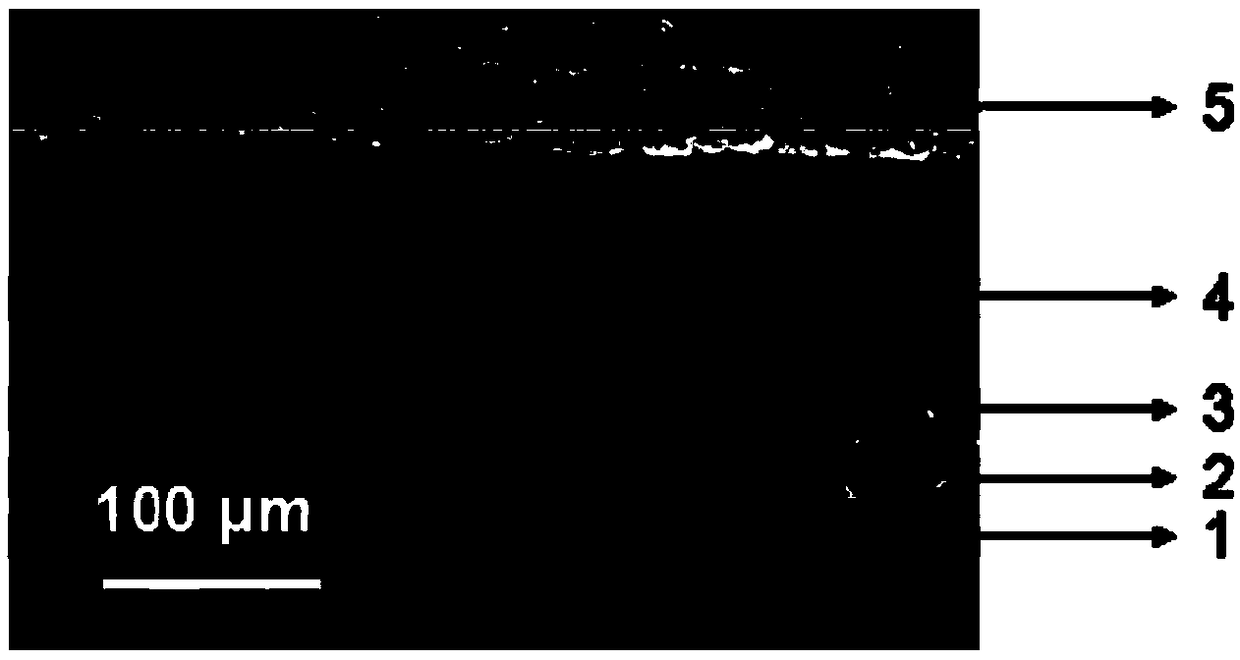

[0063] A wearable clothing sensor such as figure 1 As shown, from bottom to top, there are hydrophobic layer, fabric layer, first electrode layer, dielectric layer and second electrode layer.

[0064] Wherein, the hydrophobic layer is a silicon dioxide hydrophobic layer, the fabric layer is a cotton fabric layer, the dielectric layer is a porous cellulose acetate film layer with a porous structure, and 1-ethyl-3-methylimidazole6 Fluorophosphate; the electrode layer is a silver film layer with a mesh porous structure.

[0065] The preparation method is as follows:

[0066] (1) Mix 0.4g of silicon dioxide particles and 0.4g of polydimethylsiloxane and stir for 10 minutes to disperse evenly to prepare a casting solution;

[0067] (2) Coat the casting solution on one side of the cotton cloth and place it in a drying oven at 60°C for 2 hours to obtain a hydrophobic-fabric layer;

[0068] (3) by the spray gun spraying method, on the fabric layer other side that step (2) obtains, ...

Embodiment 2

[0072] A wearable clothing sensor consists of a hydrophobic layer, a fabric layer, a first electrode layer, a dielectric layer and a second electrode layer from bottom to top.

[0073] Wherein, the hydrophobic layer is a polytetrafluoroethylene hydrophobic layer, the fabric layer is a polyester fabric layer, the dielectric layer is a porous nitrocellulose film layer with a porous structure, and 1-ethyl-3-methylimidazole is loaded on the pore wall Tetrafluoroborate; the electrode layer is a carbon nanotube film layer with a mesh porous structure.

[0074] The preparation method is as follows:

[0075] 1) Mix 0.4g of polytetrafluoroethylene particles and 0.4g of polydimethylsiloxane and stir for 10 minutes to disperse evenly to prepare a casting solution;

[0076] 2) Coating the casting solution on the upper surface of the polyester fabric and placing it in a drying oven at 60°C for 2 hours to obtain a hydrophobic-fabric layer;

[0077] 3) Coating a carbon nanotube porous elec...

Embodiment 3

[0081] A wearable clothing sensor consists of a hydrophobic layer, a fabric layer, a first electrode layer, a dielectric layer and a second electrode layer from bottom to top.

[0082] Wherein, the hydrophobic layer is a ceramic hydrophobic layer, the fabric layer is an acrylic fabric layer, the dielectric layer is a polyurethane porous film layer with a porous structure, and 1-ethyl-3-methylimidazolium hexafluorophosphate is loaded on the hole wall; The electrode layer is a graphene film layer with a mesh porous structure.

[0083] The preparation method is as follows:

[0084] 1) Mix 0.3g ceramic particles and 0.5g epoxy resin and stir for 30min to disperse evenly to prepare casting solution;

[0085] 2) coating the casting solution obtained in step (1) on the upper surface of the acrylic fabric, and placing it at room temperature to dry naturally for 4 hours to obtain a hydrophobic-fabric layer;

[0086] 3) by the glass rod scraping film method, the other side of the fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com