Antibacterial high efficiency air filtration membrane and preparation method thereof

A high-efficiency air filtration and polymer technology, applied in filtration and separation, separation methods, dispersed particle filtration, etc., can solve the problems of bacterial growth and secondary damage of micro-particle filtration capacity, and achieve inhibition of bacterial growth, prevention of secondary damage, The effect of improving the filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The syringe includes a barrel body and a dispensing needle,

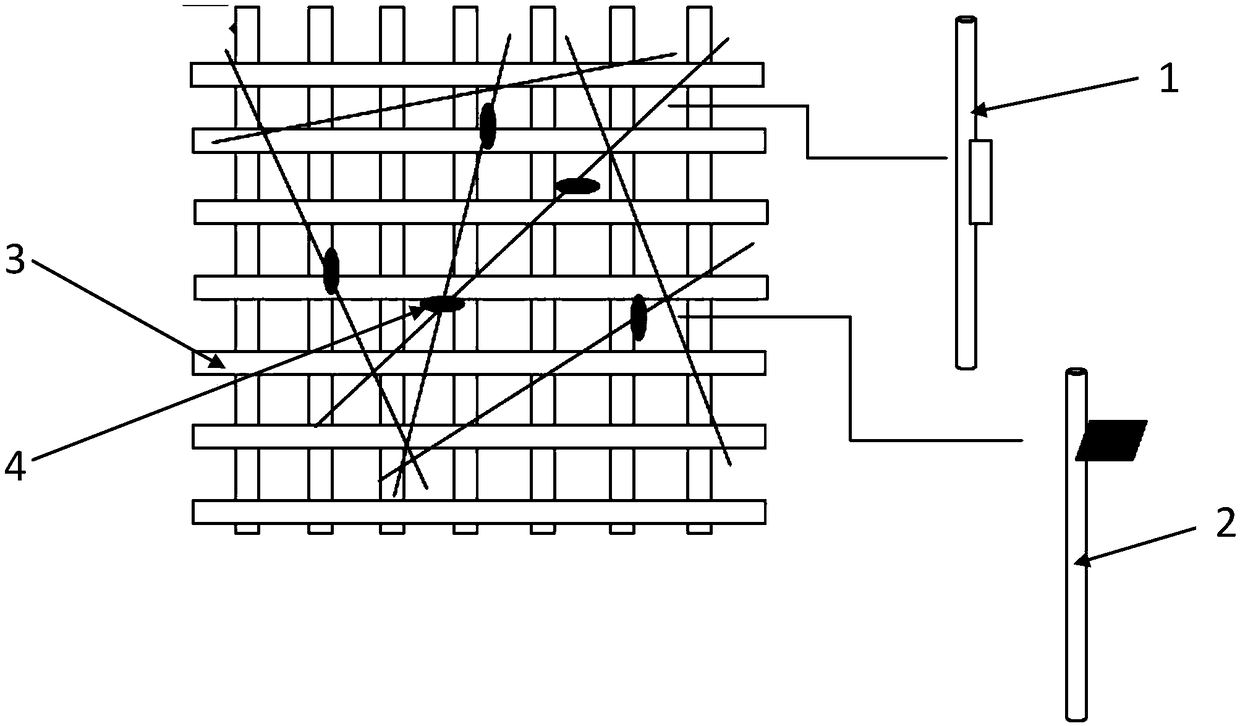

[0030] see Figure 1 to Figure 3 As shown, an antibacterial high-efficiency air filter membrane of this embodiment includes a substrate and a composite nanofiber layer, the composite nanofiber layer is covered on the substrate, and the composite nanofiber layer is completely closely attached to the substrate. The composite nanofiber layer is woven from at least three kinds of materials, the composite nanofiber layer presents a bead string structure, and the morphology of the beads is spherical, ellipsoidal, spindle-shaped or elongated spindle-shaped; the beads The average width is 200-2000 nm, and the average length is 500-3000 nm. The air filter membrane in this embodiment has a double-layer structure.

[0031] In this embodiment, the base is a non-woven fabric, and its material is one or more of polypropylene, polyacrylonitrile, polyethylene, and the like. The composite nanofiber layer is covered on the ...

Embodiment 2

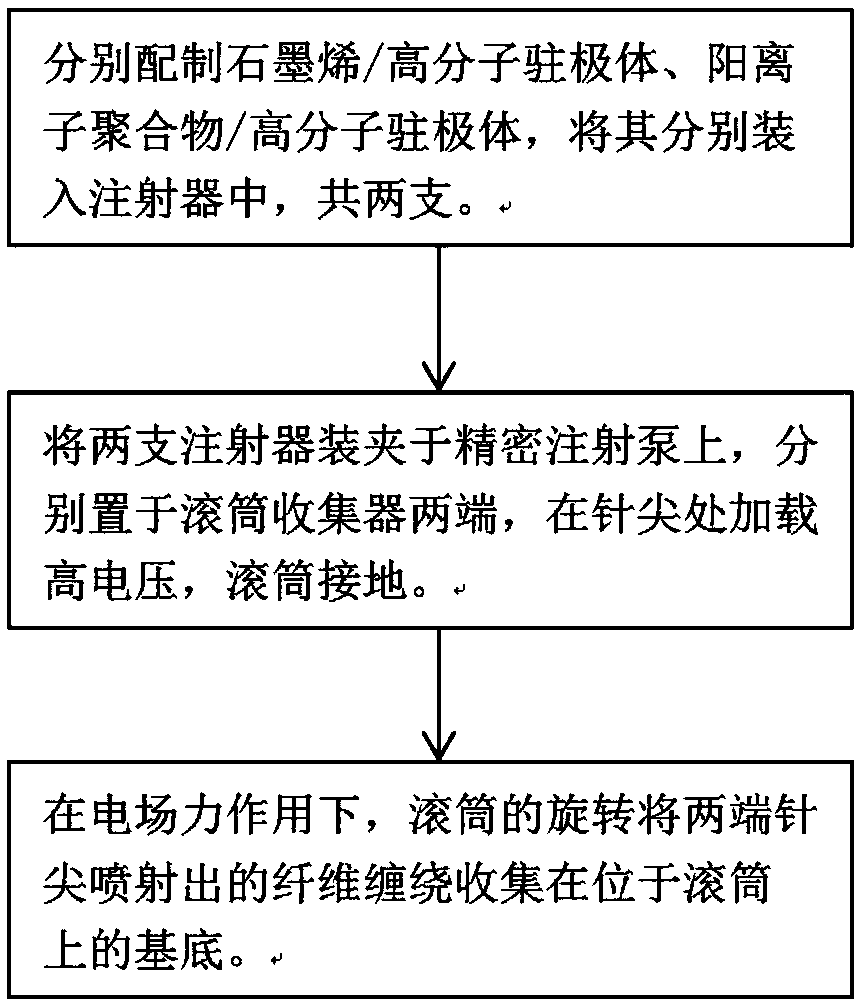

[0039] Step A, prepare 0.5mg graphene / polyvinylidene fluoride precursor solution A, weigh 0.5mg graphene, weigh 1g polyvinylidene fluoride, add 1g polyvinylidene fluoride to 5mLN,N-dimethylformamide and 5mL dimethyl ketone, and stir evenly, then add 0.5mg graphene into the polyvinylidene fluoride solution, stir evenly, and ultrasonically disperse, so that the precursor solution A is evenly dispersed.

[0040] Step B, prepare 0.5mg poly N,N-dimethylaminoethyl methacrylate / polyvinylidene fluoride precursor solution B, weigh 0.5mg poly N,N-dimethylaminoethyl methacrylate, weigh 1g of polyvinylidene fluoride, add 1g of polyvinylidene fluoride to 5mL N,N-dimethylformamide and 5mL dimethyl ketone, stir evenly, then add 0.5mg polymethacrylic acid N,N-dimethyl Add aminoethyl ester into the polyvinylidene fluoride solution, stir evenly, and disperse ultrasonically, so that the precursor solution B is uniformly dispersed.

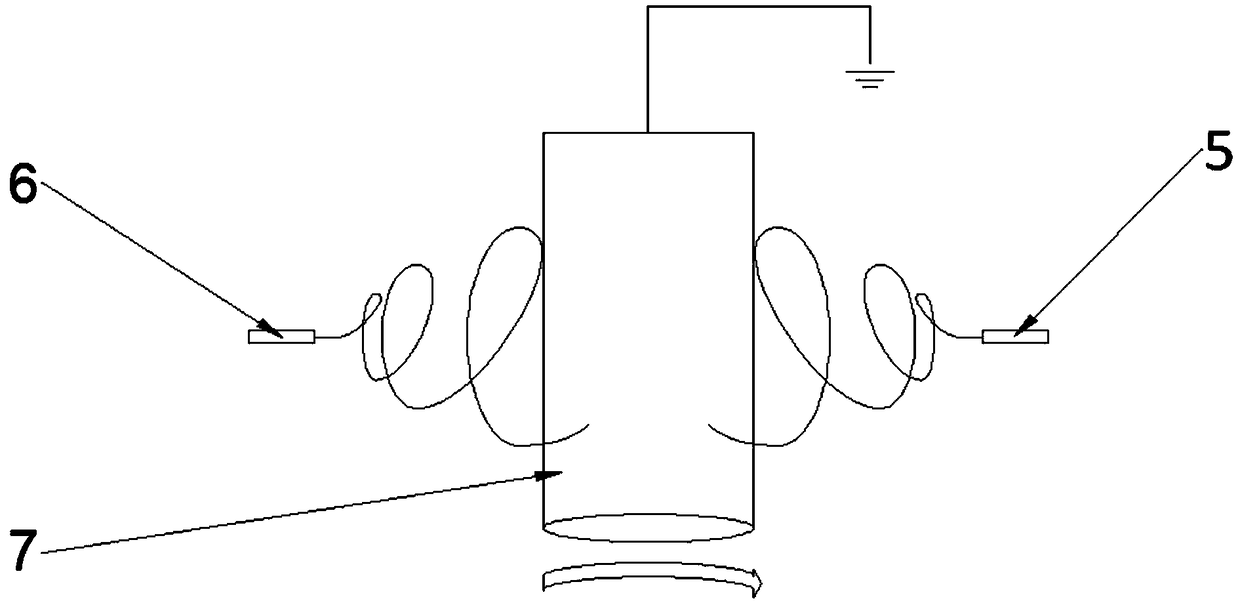

[0041] Step C, placing the non-woven fabric on the metal rolle...

Embodiment 3

[0044] Step A, prepare 19mg graphene / polyvinylidene fluoride precursor solution A, weigh 19mg graphene, weigh 1g polyvinylidene fluoride, add 1g polyvinylidene fluoride to 5mL dimethyl sulfoxide and 5mL dimethyl Ketone, stir evenly, then add 19mg of graphene into the polyvinylidene fluoride solution, stir evenly, and ultrasonically disperse, so that the precursor solution A is evenly dispersed.

[0045] Step B. Prepare 1 mg of poly(N,N-dimethylaminoethyl methacrylate-polycaprolactone / polyvinylidene fluoride) precursor solution B, and weigh 1 mg of poly(N,N-dimethylaminoethyl methacrylate-polyvinylidene fluoride) Caprolactone, weigh 1g polyvinylidene fluoride, add 1g polyvinylidene fluoride to 5mL dimethyl sulfoxide and 5mL dimethyl ketone, stir evenly, then add 1mg polymethacrylic acid N,N-di Add methylaminoethyl ester-polycaprolactone into the polyvinylidene fluoride solution, stir evenly, and ultrasonically disperse, so that the precursor solution B is evenly dispersed.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com