Phosphorus-doped functionalized mesoporous carbon material preparation method

A functionalized, mesoporous carbon technology, applied in the field of inorganic materials, can solve the problems of poor element dispersion and phosphorus doping effect, and achieve excellent effect and good element dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

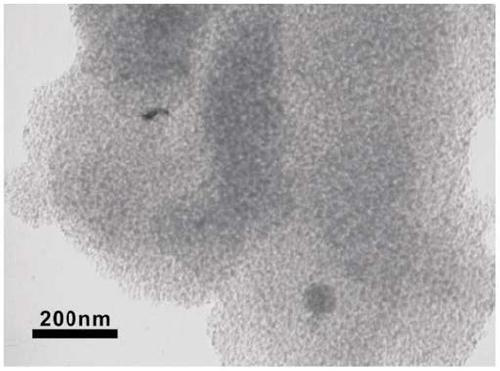

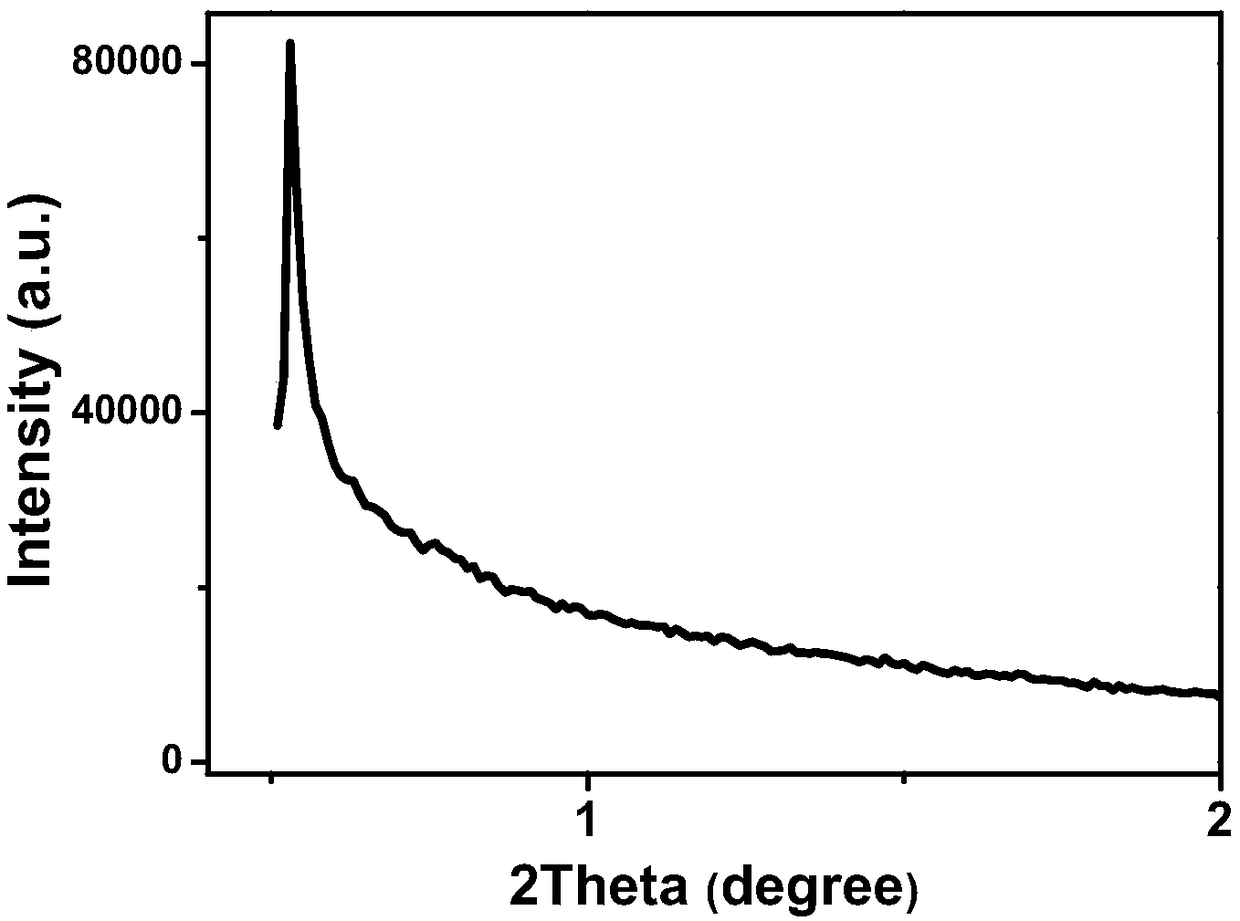

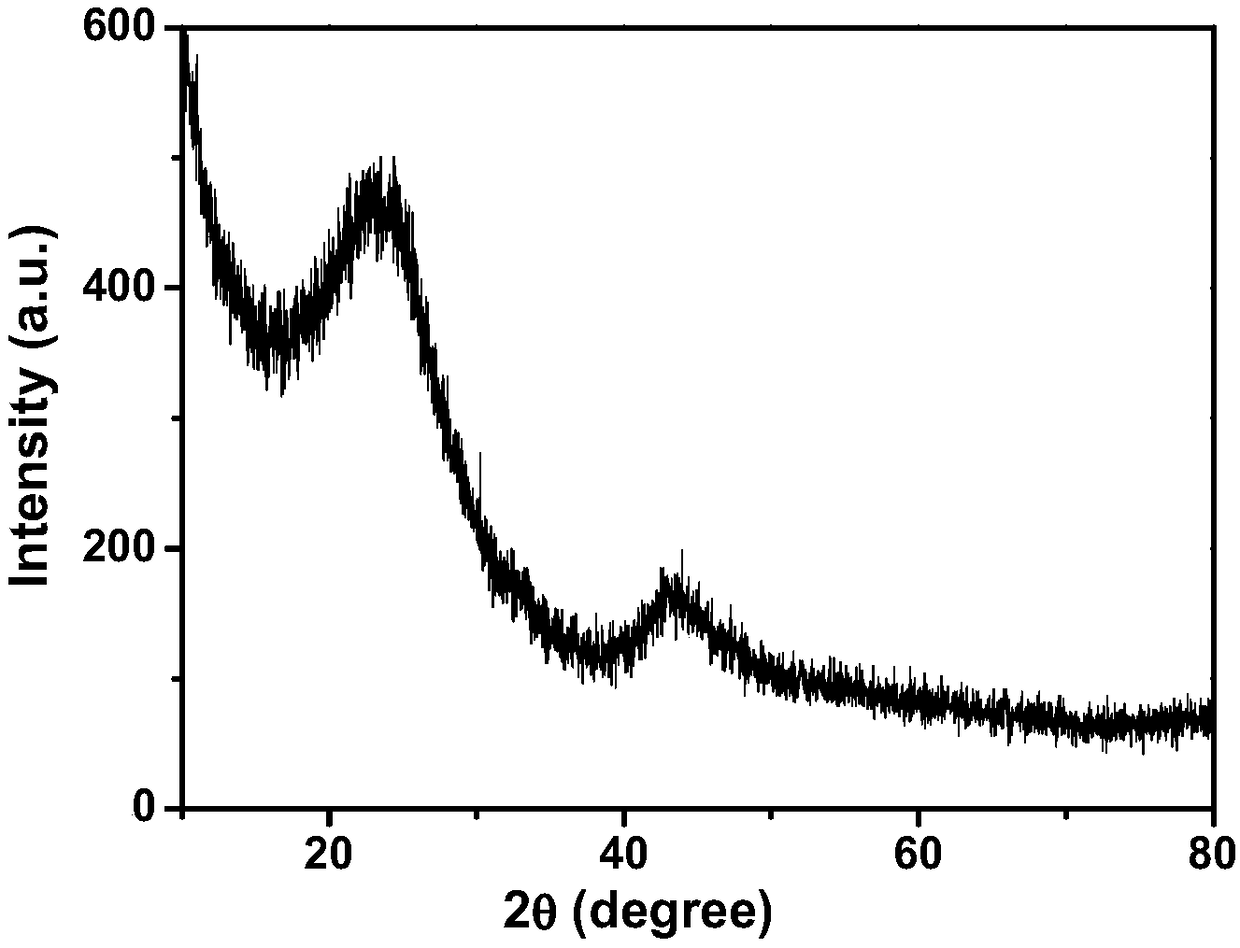

Image

Examples

Embodiment 1

[0030] A method for preparing a phosphorus-doped functionalized mesoporous carbon material, comprising the following steps:

[0031] (1) First, dissolve 1.5g of triblock copolymer in 75ml of distilled water, add 2g of sucrose, stir to dissolve, then add 0.7g of triphenylphosphine and 15ml of ethanol, stir well at room temperature, then add 6.9mL of orthosilicic acid Ethyl ester, fully stirred to obtain mixed solution A;

[0032] (2) Transfer the mixed solution A into a single-necked flask, stir in a water bath environment at 40°C, add 4.6ml of 2mol / L hydrochloric acid solution dropwise at 0.5ml / min during the stirring process, and stir overnight in the water bath environment to obtain a mixture Liquid B;

[0033] (3) Transfer the mixed solution B into an autoclave, and conduct a hydrothermal reaction at 373K for 24 hours. After the reaction is completed, remove the lower layer product and dry it at 353K to obtain a phosphorus-containing composite precursor;

[0034] (4) Carb...

Embodiment 2

[0038] A method for preparing a phosphorus-doped functionalized mesoporous carbon material, comprising the following steps:

[0039] (1) First, dissolve 3g of triblock copolymer in 30ml of distilled water, add 7.5g of sucrose, fully stir to dissolve, then add 0.2g of triphenylphosphine and 30ml of ethanol, stir well at room temperature, then add 3.4mL of orthosilicic acid Ethyl ester, fully stirred to obtain mixed solution A;

[0040] (2) Transfer the mixed solution A into a single-necked flask, stir in a 40°C water bath environment, add 10.5ml of 2mol / L hydrochloric acid solution dropwise at 0.5ml / min during the stirring process, and stir overnight in the water bath environment to obtain a mixture Liquid B;

[0041] (3) Transfer the mixed solution B into an autoclave, and conduct a hydrothermal reaction at 373K for 12 hours. After the reaction is completed, take the lower layer product and dry it at 353K to obtain a phosphorus-containing composite precursor;

[0042] (4) Carb...

Embodiment 3

[0046] A method for preparing a phosphorus-doped functionalized mesoporous carbon material, comprising the following steps:

[0047] (1) First, dissolve 1.5g of triblock copolymer in 30ml of distilled water, add 7.5g of sucrose, stir to dissolve, then add 0.7g of triphenylphosphine and 15ml of ethanol, stir at room temperature, and then add 3.4mL of orthosilicon Ethyl acetate, fully stirred to obtain mixed solution A;

[0048] (2) Transfer the mixed solution A into a single-necked flask, stir in a 40°C water bath environment, add 10.5ml of 2mol / L hydrochloric acid solution dropwise at 0.5ml / min during the stirring process, and stir overnight in the water bath environment to obtain a mixture Liquid B;

[0049] (3) Transfer the mixed solution B into an autoclave, and conduct a hydrothermal reaction at 373K for 24 hours. After the reaction is completed, remove the lower layer product and dry it at 353K to obtain a phosphorus-containing composite precursor;

[0050] (4) Carboniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com