Modular composite advanced treatment system and operation method for low-concentration heavy metal wastewater

A low-concentration heavy metal, advanced treatment technology, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc. Effects of adsorption activity and adsorption capacity, increasing specific surface area, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] The effluent quality of the sewage discharge outlet of an electroplating factory meets the standard discharge, and the concentration of heavy metal Cd is 0.5mg / L at this time.

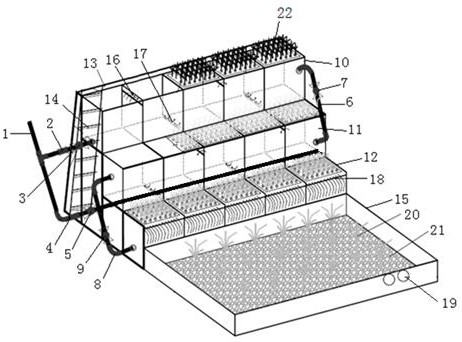

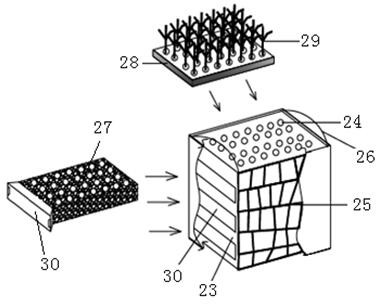

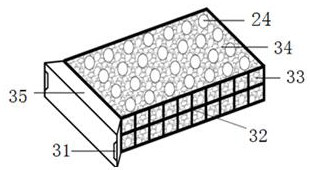

[0095] Adopt the system of the present invention to carry out compound processing, processing scale 50m 3 / d. Seven adsorption units are arranged in each layer of water collection tank, the size of the adsorption filling layer in each water collection tank is 65cm×65cm×5cm, and the filling capacity of each adsorption unit is about m=36kg. The plant cultivation tray 28 in the three-layer water collection tank is matched with planting aquatic plants Erythrina chinensis and cattail, and in the water collection buffer tank 15, the aquatic plant reed is planted.

[0096] Wastewater containing low-concentration heavy metal Cd has reached a concentration of 0.002 mg / L through this modular composite advanced treatment method. After 6 months of continuous operation, the quality of the effluent is stable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com