Tempered glass and production process thereof

A tempered glass and glass technology, applied in the field of glass processing, can solve the problems such as edge chipping and warping of tempered glass, and achieve the effects of good application prospect, small wear amount and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

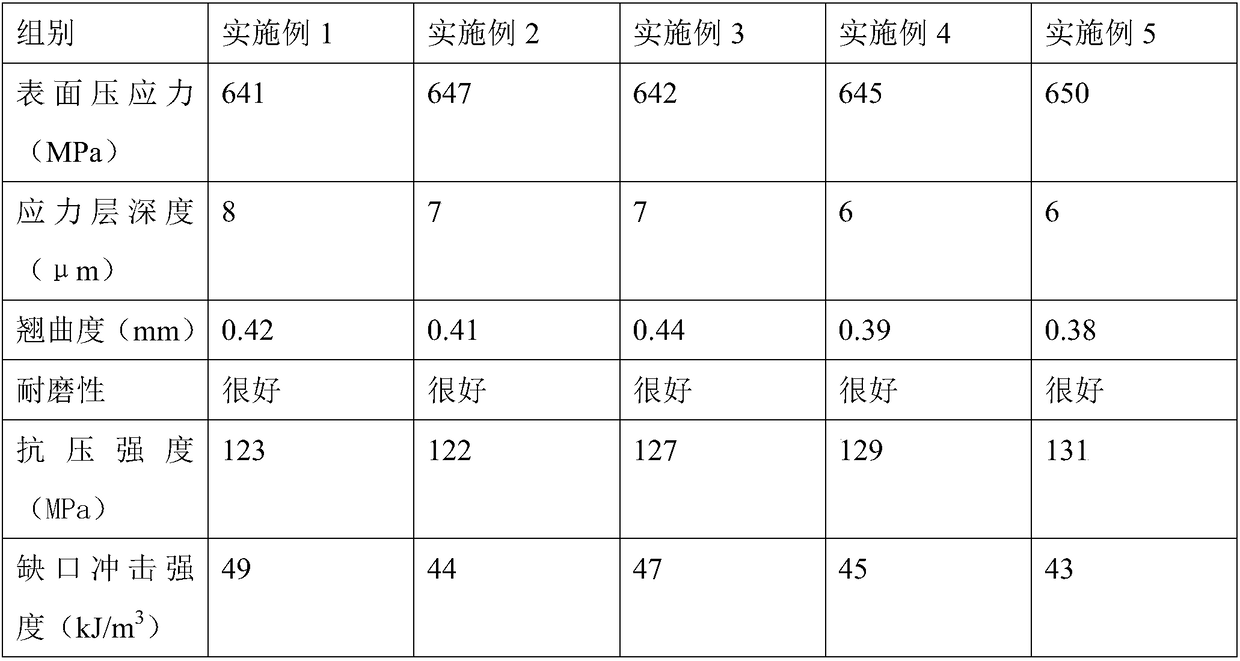

Examples

Embodiment 1

[0023] Raw material composition (parts by weight): 50 parts of sodium silicate pellets, 30 parts of potassium silicate pellets, 10 parts of anorthite, 15 parts of quartz sand, 7 parts of graphene, 5 parts of alumina, 3 parts of cerium oxide, oxide 2 parts of niobium, 10 parts of slaked lime, 2 parts of clarifying agent, 1 part of ultraviolet absorber and 2 parts of impact modifier.

[0024] The composition of the clarifying agent fatty alcohol citric acid and propylene glycol has a mass ratio of 1:1.

[0025] The ultraviolet absorber is a compound ultraviolet absorber composed of UV531 and UV1164, and the mass ratio is 5:2.

[0026] The impact modifier is a mixture of glass microbeads, emery and carbon black, and the mass ratio is 1:1:2.

[0027] A kind of tempered glass production process, according to the following steps:

[0028] S1. The glass products to be tempered are cut and edged, washed and dried with water, ethanol and deionized water in sequence, and placed in a stainless st...

Embodiment 2

[0031] Raw material composition (parts by weight): 80 parts of sodium silicate pellets, 50 parts of potassium silicate pellets, 20 parts of anorthite, 25 parts of quartz sand, 12 parts of graphene, 12 parts of alumina, 8 parts of cerium oxide, oxide 6 parts of niobium, 15 parts of slaked lime, 5 parts of clarifying agent, 3 parts of ultraviolet absorber and 4 parts of impact modifier.

[0032] The composition of the clarifying agent fatty alcohol citric acid and propylene glycol has a mass ratio of 1:1.

[0033] The ultraviolet absorber is a compound ultraviolet absorber composed of UV531 and UV1164, and the mass ratio is 5:2.

[0034] The impact modifier is a mixture composed of glass beads, emery and carbon black, and the mass ratio is 1:1:2.

[0035] A kind of tempered glass production process, according to the following steps:

[0036] S1. The glass products to be tempered are cut and edged, washed and dried with water, ethanol and deionized water in sequence, and placed in a stain...

Embodiment 3

[0039] Raw material composition (parts by weight): 60 parts of sodium silicate pellets, 35 parts of potassium silicate pellets, 12 parts of anorthite, 17 parts of quartz sand, 8 parts of graphene, 7 parts of alumina, 4 parts of cerium oxide, oxide 3 parts of niobium, 11 parts of slaked lime, 3 parts of clarifying agent, 2 parts of ultraviolet absorber and 2 parts of impact modifier.

[0040] The composition of the clarifying agent fatty alcohol citric acid and propylene glycol has a mass ratio of 1:1.

[0041] The ultraviolet absorber is a compound ultraviolet absorber composed of UV531 and UV1164, and the mass ratio is 5:2.

[0042] The impact modifier is a mixture composed of glass beads, emery and carbon black, and the mass ratio is 1:1:2.

[0043] A kind of tempered glass production process, according to the following steps:

[0044] S1. The glass products to be tempered are cut and edged, washed and dried with water, ethanol and deionized water in sequence, and placed in a stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com