Semi-tempered vacuum glass and sealing and connecting method thereof

A vacuum glass, semi-tempering technology, applied in glass tempering, glass manufacturing equipment, furnace types, etc., can solve the problems of cracking, vacuum glass losing vacuum degree, etc., achieve the effect of small thickness, avoid annealing, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

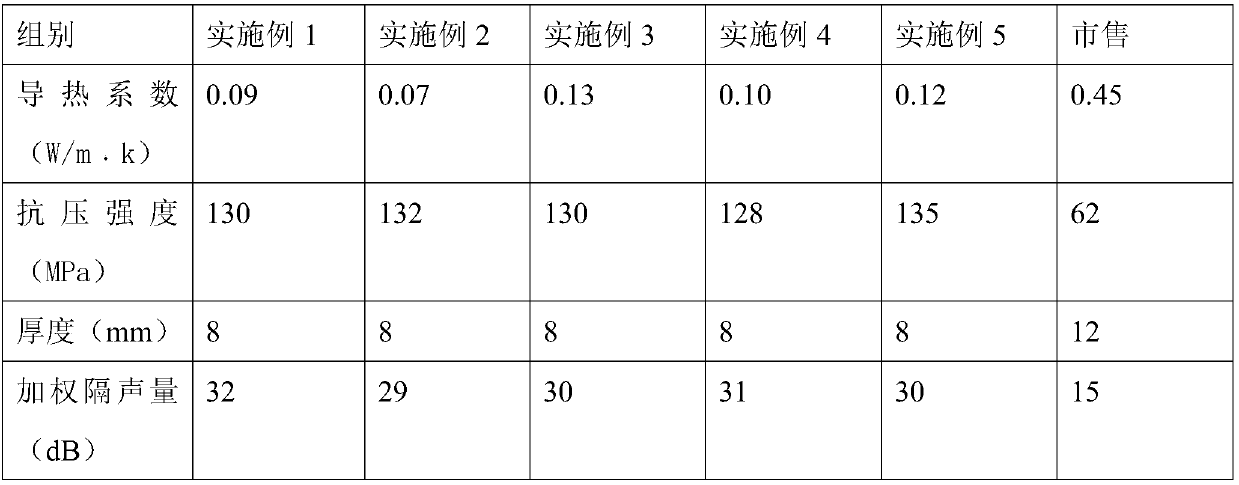

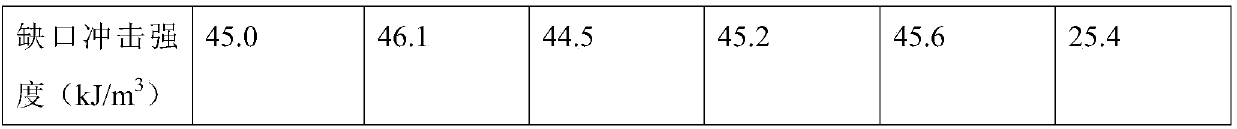

Examples

Embodiment 1

[0024] A semi-tempered vacuum glass is obtained by processing high-strength flat semi-tempered glass.

[0025] Preparation of high-strength flat semi-tempered glass:

[0026] Composition of raw materials (parts by weight): 100 parts of sodium silicate pellets, 30 parts of PVC resin, 20 parts of silicon dioxide, 15 parts of aluminum oxide, 10 parts of magnesium oxide, 12 parts of carbon fiber, 10 parts of silicon nitride, 5 parts of borax, 3 parts of basalt, 3 parts of impact modifier, 1 part of tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 1 part of UV absorber UV1164 and polyethylene glycol Alcohol 4000 25 parts.

[0027] The impact modifier is a mixture of hollow glass microspheres, corundum and diatomaceous earth in a weight ratio of 0.3:0.5:1.

[0028] Prepared by:

[0029] S1. Accurately weigh each raw material according to the formula, mix them and grind them evenly in an agate mortar, then pour the sample into a corundum crucible...

Embodiment 2

[0036] A semi-tempered vacuum glass is obtained by processing high-strength flat semi-tempered glass.

[0037] Preparation of high-strength flat semi-tempered glass:

[0038] Composition of raw materials (parts by weight): 130 parts of sodium silicate pellets, 50 parts of PVC resin, 40 parts of silicon dioxide, 20 parts of aluminum oxide, 16 parts of magnesium oxide, 15 parts of carbon fiber, 13 parts of silicon nitride, 10 parts of borax, 7 parts of basalt, 5 parts of impact modifier, 3 parts of tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 2 parts of ultraviolet absorber UV120 and polyethylene glycol Alcohol 4000 35 parts.

[0039]The impact modifier is a mixture of hollow glass microspheres, corundum and diatomaceous earth in a weight ratio of 0.3:0.5:1.

[0040] Prepared by:

[0041] S1. Accurately weigh each raw material according to the formula, mix them and grind them evenly in an agate mortar, then pour the sample into a corundu...

Embodiment 3

[0048] A semi-tempered vacuum glass is obtained by processing high-strength flat semi-tempered glass.

[0049] Preparation of high-strength flat semi-tempered glass:

[0050] Composition of raw materials (parts by weight): 110 parts of sodium silicate pellets, 35 parts of PVC resin, 25 parts of silicon dioxide, 16 parts of aluminum oxide, 12 parts of magnesium oxide, 13 parts of carbon fiber, 11 parts of silicon nitride, 7 parts of borax, 4 parts of basalt, 4 parts of impact modifier, 1 part of bis(3,5-tertiary butyl-4-hydroxyphenyl) sulfide, 1.2 parts of ultraviolet absorber UV284 and 27 parts of polyethylene glycol 4000.

[0051] The impact modifier is a mixture of hollow glass microspheres, corundum and diatomaceous earth in a weight ratio of 0.3:0.5:1.

[0052] Prepared by:

[0053] S1. Accurately weigh each raw material according to the formula, mix them and grind them evenly in an agate mortar, then pour the sample into a corundum crucible preheated at 200°C, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com