Temperature difference resistant high-wear-resistant butadiene styrene rubber cable material for sandy area and preparation method of cable material

The technology of rubber cable and styrene-butadiene rubber is applied in the field of temperature difference resistance, high wear-resisting styrene-butadiene rubber cable material and its preparation field. Demand, erosion, friction, cable service life decline and other issues, to achieve the effect of broad market application prospects, excellent temperature difference resistance, excellent high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

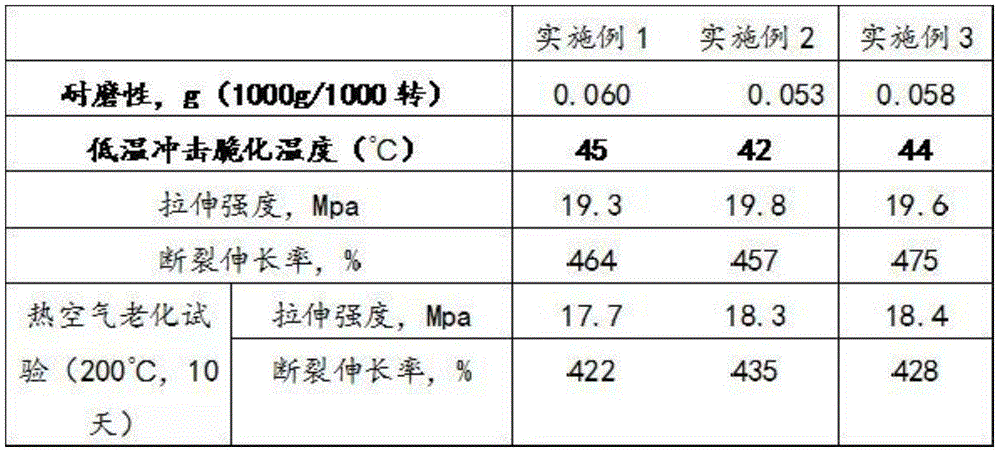

Examples

Embodiment 1

[0014] A styrene-butadiene rubber cable material with high temperature difference resistance and high wear resistance used in windy and sandy areas, which is prepared from the following raw materials in parts by weight (kg): styrene-butadiene rubber 130, acrylate rubber 12, diallyl phthalate 8 , ramie fiber 20, Fischer-Tropsch wax 4, polyether polyurethane 5, bis(dioctyloxypyrophosphate) ethylene titanate 2, barium metaphosphate 5, aluminum distearate 6, 2,6- Tertiary butyl-4-methylphenol 7, zinc methacrylate 4, calcined loess 20, high wear-resistant carbon black 30, triethylene glycol diisocaprylate 6, zinc stannate 2, diisopropyl peroxide Benzene 3, sulfur 1, calcium molybdate 4, triethyl citrate 5, zirconium carbide 8, chromium carbide 10.

[0015] A kind of preparation method of the styrene-butadiene rubber cable material with high resistance to temperature difference and high wear resistance used in windy and sandy areas, comprising the following steps:

[0016] (1) Styr...

Embodiment 2

[0020] A styrene-butadiene rubber cable material with high temperature difference resistance and high wear resistance used in windy and sandy areas. It is prepared from the following raw materials in parts by weight (kg): styrene-butadiene rubber 140, acrylate rubber 14, diallyl phthalate 10 , ramie fiber 25, Fischer-Tropsch wax 5, polyether polyurethane 7, bis(dioctyloxypyrophosphate) ethylene titanate 3, barium metaphosphate 6, aluminum distearate 7, 2,6- Tertiary butyl-4-methylphenol 8, zinc methacrylate 5.5, calcined loess 22.5, high wear-resistant carbon black 32.5, triethylene glycol diisocaprylate 8, zinc stannate 3, diisopropyl peroxide Benzene 3.5, sulfur 1.5, calcium molybdate 4.5, triethyl citrate 7.5, zirconium carbide 9, chromium carbide 11.

[0021] The preparation method is the same as in Example 1.

Embodiment 3

[0023] A styrene-butadiene rubber cable material with high temperature difference resistance and high wear resistance used in windy and sandy areas. It is prepared from the following raw materials in parts by weight (kg): styrene-butadiene rubber 150, acrylate rubber 16, diallyl phthalate 12 , ramie fiber 30, Fischer-Tropsch wax 6, polyether polyurethane 9, bis(dioctyloxypyrophosphate) ethylene titanate 4, barium metaphosphate 7, aluminum distearate 8, 2,6- Tertiary butyl-4-methylphenol 9, zinc methacrylate 7, calcined loess 25, high wear-resistant carbon black 35, triethylene glycol diisocaprylate 10, zinc stannate 4, diisopropyl peroxide Benzene 4, sulfur 2, calcium molybdate 5, triethyl citrate 10, zirconium carbide 10, chromium carbide 12.

[0024] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com