Mixed explosive for detonators, and preparation method thereof

A technology of mixing explosives and detonators, which is applied in the direction of explosives, non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, etc., which can solve problems such as inconvenient production, poor cohesive force, and difficult granulation , to achieve the effects of low production cost, good cohesive force and good granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

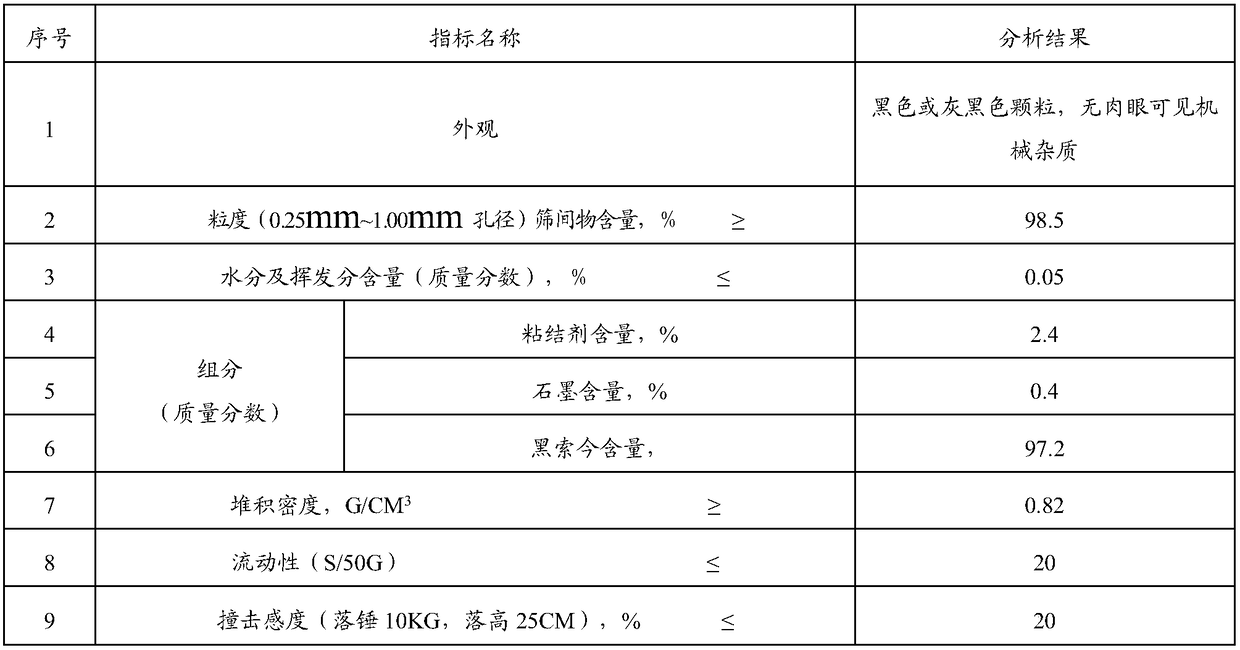

Examples

preparation example Construction

[0032] The present invention also provides a preparation method for the mixed explosive for the detonator described in the above technical solution, comprising the following steps:

[0033] (1) cyclotrimethylenetriammonium trinitrate is mixed with water to obtain a suspension;

[0034] (2) The suspension obtained in the step (1) is mixed with polyvinyl acetate emulsion and 551 glue to obtain a mixed solution;

[0035] (3) mixing the mixed solution obtained in the step (2) with a demulsifier to obtain a clear solution;

[0036] (4) The clear solution obtained in the step (3) is heated and mixed with ethyl acetate for granulation;

[0037] (5) removing ethyl acetate in the granulated product obtained in the step (4);

[0038] (6) filtering the product obtained in step (5) after removing ethyl acetate to obtain material;

[0039] (7) The material obtained in the step (6) is sequentially washed, dried and graphite passivated to obtain a mixed explosive for a detonator.

[0040...

Embodiment 1

[0056] (1) the cyclotrimethylenetriammonium trinitrate of 90kg is put into 108kg water, stir to obtain suspension;

[0057] (2) Add 3.86kg of polyvinyl acetate and 0.58kg of 551 glue to the suspension, and stir evenly;

[0058] (3) Add 10 kg of anhydrous sodium sulfate again, and the mass concentration is 5 L of 15% calcium chloride aqueous solution, and stir to obtain a clear solution;

[0059] (4) Heat the obtained clear solution to 55°C at a heating rate of 2°C / min, add ethyl acetate at a rate of 10mL / min for granulation, and control the amount of ethyl acetate added by sampling and observing the size of the white particles ;

[0060] (5) When the white particle size reaches the particle size between 0.25mm~1.00mm (80mesh~60mesh), stop adding ethyl acetate, open the vacuum system (vacuum degree is 0.02MPa), and heat the mixed solution to Distill ethyl acetate at 80°C;

[0061] (6) After the distillation of ethyl acetate is completed, the mixed solution is cooled to 50° C...

Embodiment 2

[0066] (1) the cyclotrimethylenetriammonium trinitrate of 90kg is put into 130kg water, stir to obtain suspension;

[0067] (2) Add 3.86kg of polyvinyl acetate and 0.58kg of 551 glue to the suspension, and stir evenly;

[0068] (3) Add 10 kg of anhydrous sodium sulfate again, and the mass concentration is 5 L of 15% calcium chloride aqueous solution, and stir to obtain a clear solution;

[0069] (4) Heat the obtained clear solution to 55°C at a heating rate of 2°C / min, add ethyl acetate at a rate of 10mL / min for granulation, and control the amount of ethyl acetate added by sampling and observing the size of the white particles ;

[0070] (5) When the white particle size reaches the particle size between 0.25mm~1.00mm (80mesh~60mesh), stop adding ethyl acetate, open the vacuum system (vacuum degree is 0.02MPa), and heat the mixed solution to Distill ethyl acetate at 80°C;

[0071] (6) After the distillation of ethyl acetate is completed, the mixed solution is cooled to 50° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com