Rosin-cellulose-based polyesterimide polymer, and preparation method and application thereof

A technology based on polyesterimide and cellulose, applied in the field of bio-based polymer amphiphilic polymer preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

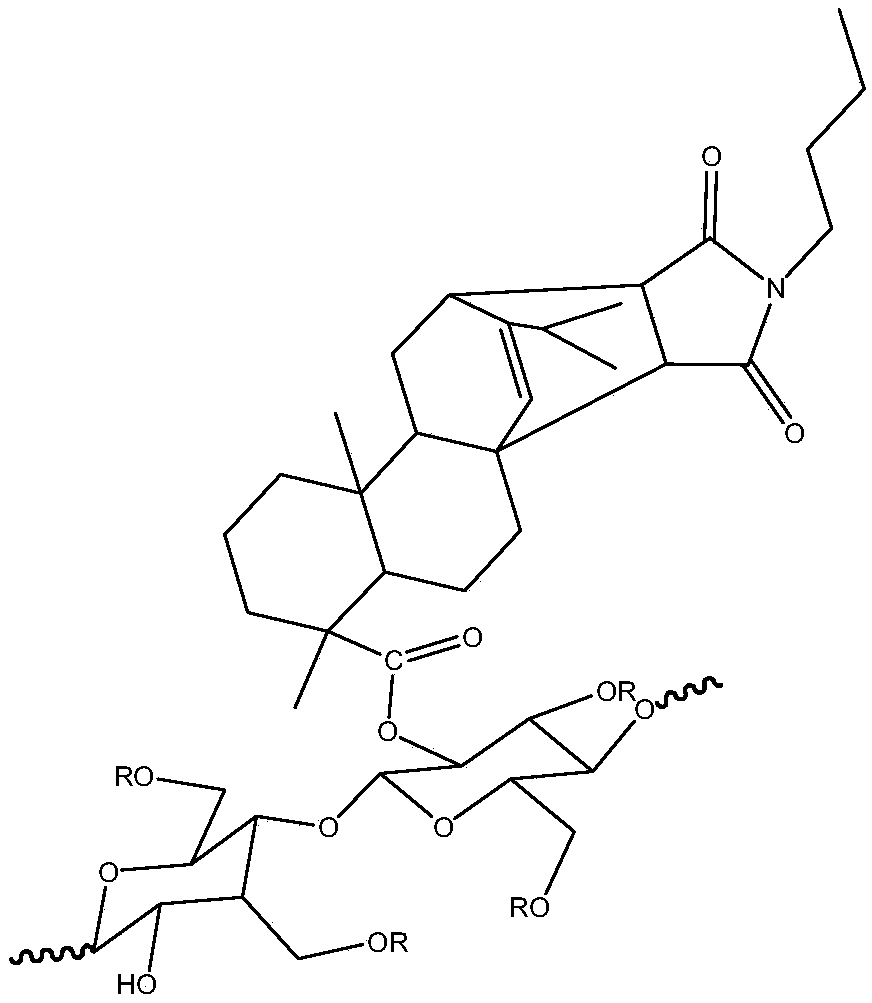

Method used

Image

Examples

Embodiment 1

[0029] In the first step, add 100g of gum rosin, 32.7g of maleic anhydride, 100g of glacial acetic acid, and 0.02g of p-toluenesulfonic acid into a 500mL four-neck flask, add them into the reactor, start stirring, and reflux at 120°C for 5 hours under nitrogen gas. After the product was cooled to room temperature, it was recrystallized three times with glacial acetic acid, and dried in vacuum at 120°C for 5 hours to obtain MPA;

[0030] In the second step, 26g MPA (0.065mol, about 1.3 times of EC) was dissolved in 40mL THF, and 7.2mL oxalyl chloride (0.0845mol, 10.7g) was added dropwise at 0°C, and reacted at 50°C for 2 hours (dropping A small amount of DMF, 0.35mL, about 5wt.% of MPA, passed through molecular sieves before use). Remove the reactant and evaporate to dryness at 50°C, then add 40mL THF, and evaporate to dryness; then add 40mL THF and evaporate to dryness to obtain the intermediate product MPACl;

[0031] In the third step, MPACl was dissolved in THF and dropped...

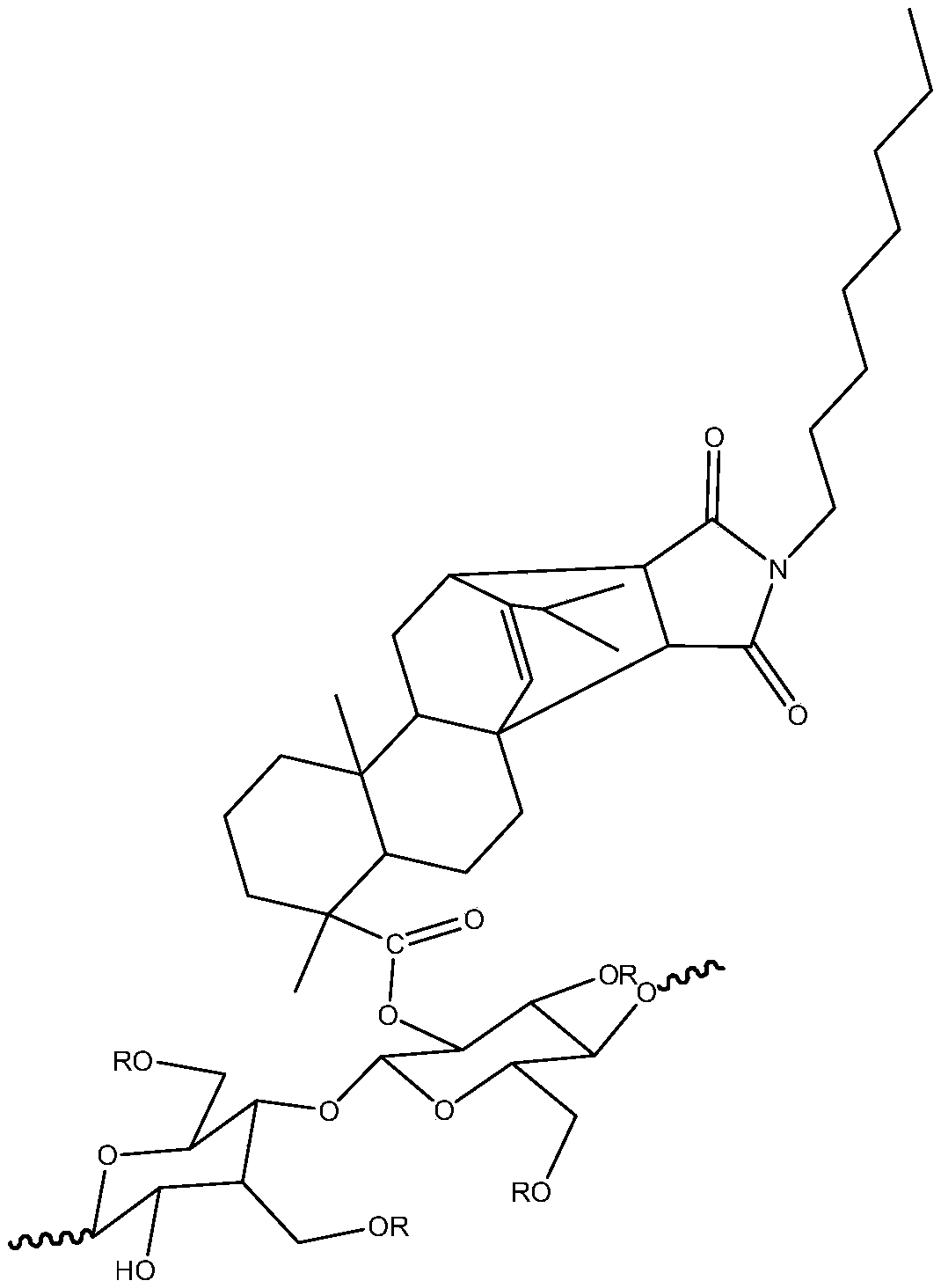

Embodiment 2

[0034] In the first step, add 100g of gum rosin, 32.7g of maleic anhydride, 100g of glacial acetic acid, and 0.02g of p-toluenesulfonic acid into a 500mL four-neck flask, start stirring, and reflux at 120°C for 5 hours under nitrogen, and cool the product to After room temperature, recrystallize three times with glacial acetic acid, and dry in vacuum at 120°C for 5 hours to obtain MPA;

[0035] In the second step, 26g MPA (0.065mol, about 1.3 times of EC) was dissolved in 40mL THF, and 7.2mL oxalyl chloride (0.0845mol, 10.7g) was added dropwise at 0-5°C, and reacted at 50°C for 2 hours ; (drop a small amount of DMF, 0.35mL, about 5wt.% of MPA, pass through molecular sieves before use). Remove the reactant and evaporate to dryness at 50°C, then add 40mL THF, and evaporate to dryness; then add 40mL THF and evaporate to dryness to obtain the intermediate product MPACl;

[0036] In the third step, MPACl was dissolved in THF and dropped into a flask containing 12.3g EC (0.05mol), ...

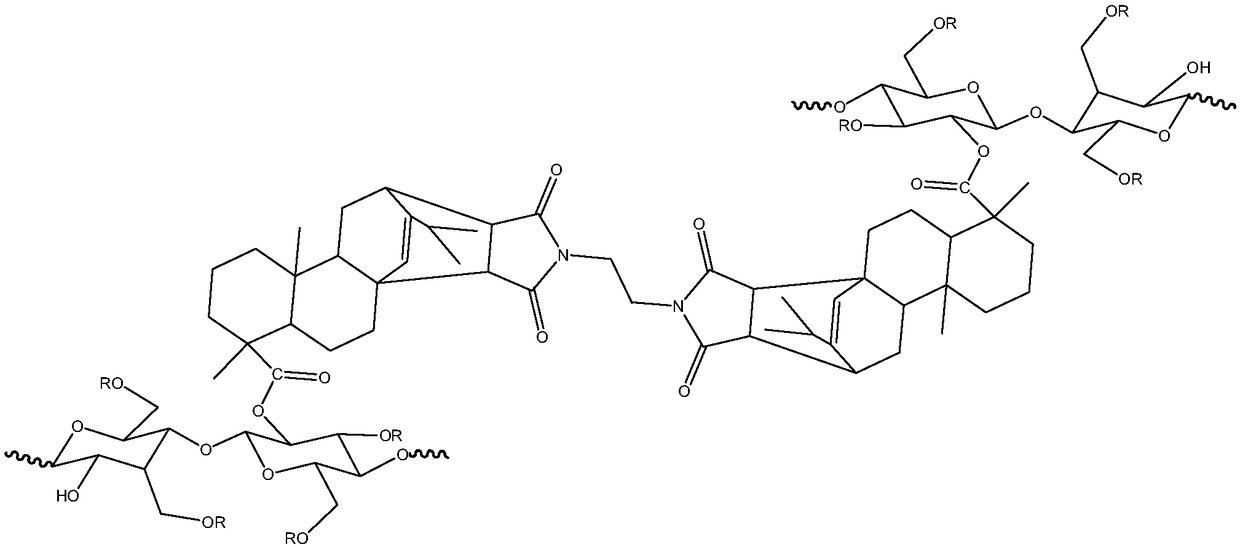

Embodiment 3

[0039] In the first step, add 100g of gum rosin, 32.7g of maleic anhydride, 100g of glacial acetic acid, and 0.02g of p-toluenesulfonic acid into a 500mL four-neck flask, start stirring, and reflux at 120°C for 5 hours under nitrogen, and cool the product to After room temperature, recrystallize three times with glacial acetic acid, and dry in vacuum at 120°C for 5 hours to obtain MPA;

[0040] In the second step, 26g of MPA (0.065mol, about 1.3 times of EC) was dissolved in 40mL of THF, and 7.2mL of oxalyl chloride (0.0845mol, 10.7g) was added dropwise at 0°C, and reacted at 50°C for 2 hours; ( Add a small amount of DMF, 0.35mL, about 5wt.% of MPA, pass through molecular sieves before use). Remove the reactant and evaporate to dryness at 50°C, then add 40mL THF, and evaporate to dryness; then add 40mL THF and evaporate to dryness to obtain the intermediate product MPACl;

[0041] In the third step, MPACl was dissolved in THF and dropped into a flask containing 12.3g EC (0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com