Flexible high-frequency electromagnetic shielding material with dual-network structure, and preparation method thereof

A high-frequency electromagnetic and shielding material technology, applied in the fields of magnetic/electric field shielding, electrical components, etc., can solve the problems of high conductive filler content, surface coating instability limiting application, affecting the lightweight and flexible properties of polymer matrix, etc. Achieve the effect of improving modulus and strength, excellent electromagnetic shielding effect, and excellent electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

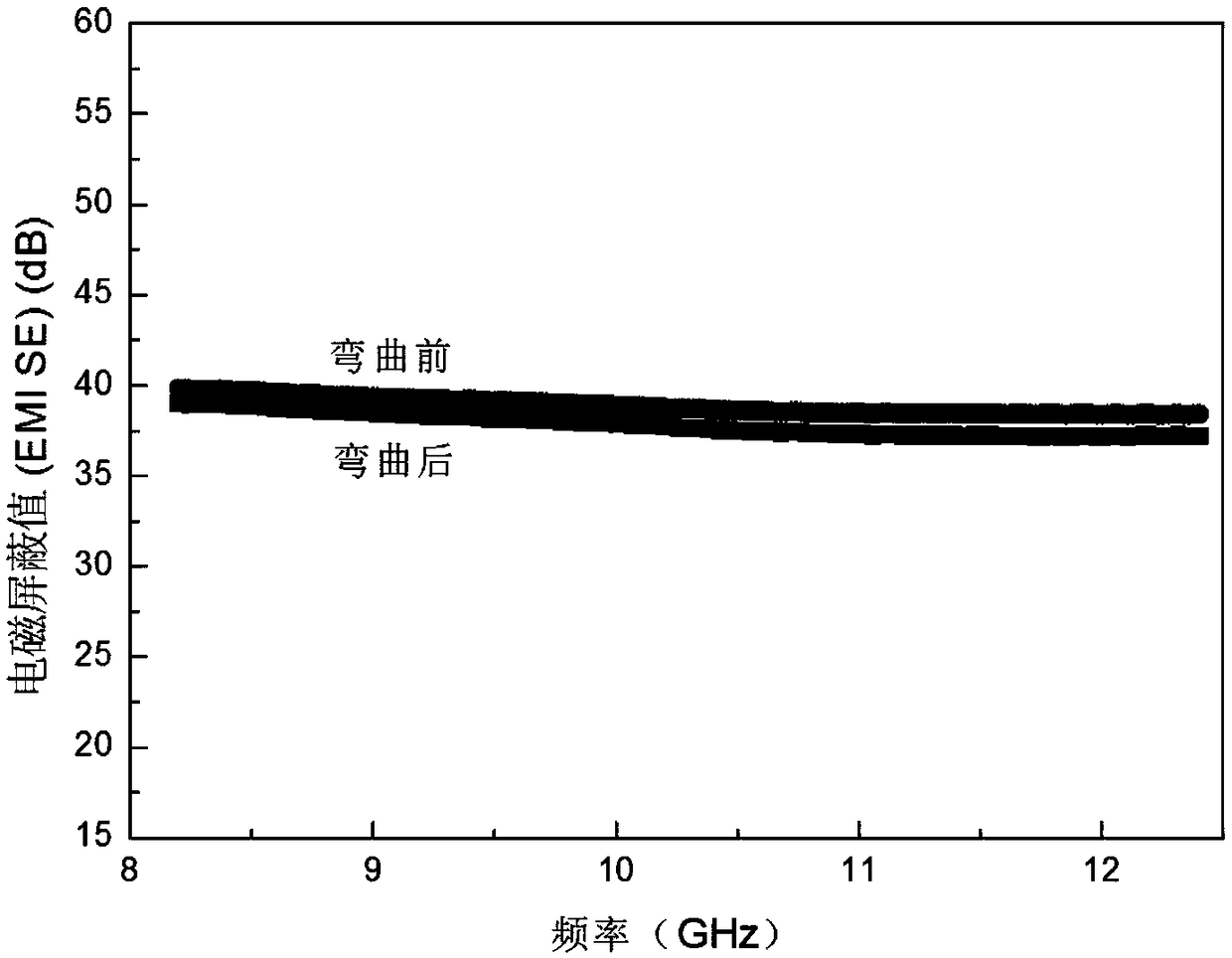

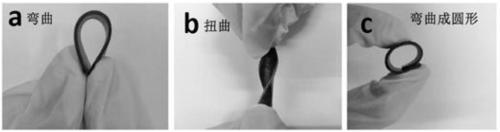

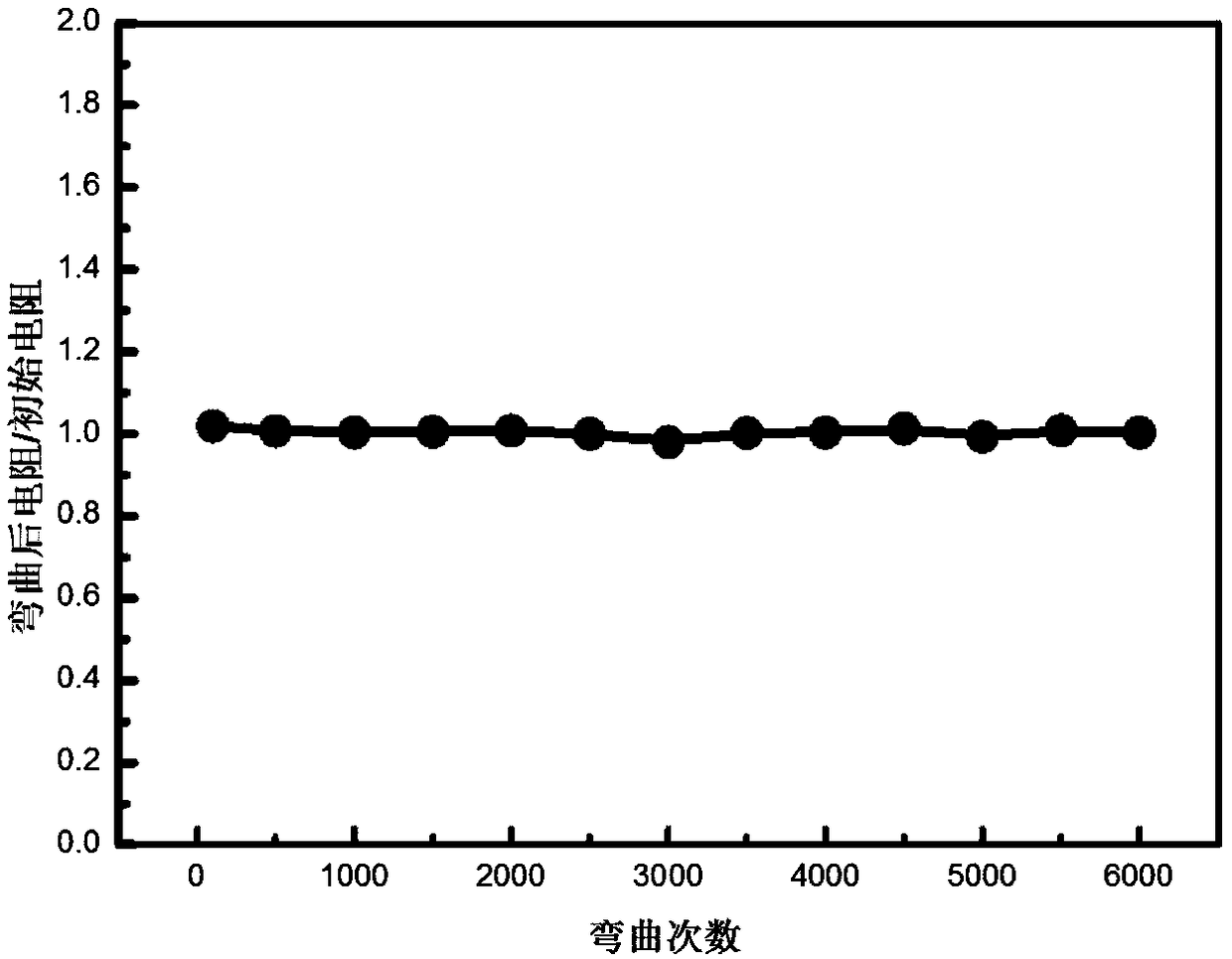

[0035] A flexible high-frequency electromagnetic shielding material with a double network structure, which consists of the following components in parts by mass: 8 parts of single-walled carbon nanotubes, 7 parts of cotton fibers, and 33 parts of polydimethylsiloxane. The high-frequency electromagnetic shielding material was prepared as follows: 8 parts of single-walled carbon nanotubes, 7 parts of cotton fibers and 33 parts of polydimethylsiloxane prepolymer were added to dichloromethane and mixed by mechanical stirring, and then press 10% of the weight of the dimethylsiloxane prepolymer is added with a curing agent, and the dichloromethane is removed under a vacuum condition of 45°C after being mixed again by mechanical stirring, and finally put into a mold, and molded at 100°C to produce Obtain flexible high-frequency electromagnetic shielding materials. After testing, the electromagnetic shielding effectiveness of the flexible high-frequency electromagnetic shielding mater...

Embodiment 2

[0037] A flexible high-frequency electromagnetic shielding material with a double network structure consists of the following components in parts by mass: 5 parts of multilayer graphene, 15 parts of nylon fiber, and 60 parts of polydimethylsiloxane. The high-frequency electromagnetic shielding material was prepared as follows: 5 parts of multilayer graphene, 15 parts of nylon fiber and 60 parts of polydimethylsiloxane prepolymer were added into tetrahydrofuran and mixed by ultrasonic, and then pressed by dimethylsiloxane 10% of the weight of the alkane prepolymer is added with a curing agent, and the tetrahydrofuran is removed under a vacuum condition of 45°C after ultrasonic mixing again, and finally put into a mold and molded at 100°C to obtain a flexible high-frequency electromagnetic shielding material. After testing, the electromagnetic shielding effectiveness of the flexible high-frequency electromagnetic shielding material in the X-band can reach ~35dB, that is, the comp...

Embodiment 3

[0039]A flexible high-frequency electromagnetic shielding material with a double network structure consists of the following components in parts by mass: 6 parts of single-walled carbon nanotubes, 30 parts of polypropylene fibers, 70 parts of polydimethylsiloxane, the The flexible high-frequency electromagnetic shielding material was prepared as follows: 6 parts of single-walled carbon nanotubes, 30 parts of polypropylene fibers and 70 parts of polydimethylsiloxane prepolymer were added to acetone and mixed by mechanical stirring, and then press 10% of the weight of the dimethylsiloxane prepolymer is added with a curing agent, and the acetone is removed under a vacuum condition of 45°C after mechanical stirring and mixing again, and finally put into a mold and molded at 100°C to obtain a flexible High frequency electromagnetic shielding material. After testing, the electromagnetic shielding effectiveness of the flexible high-frequency electromagnetic shielding material in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com