Infrared-reflection nanometer titanium dioxide powder coating and preparation method thereof

A nano-titanium dioxide, powder coating technology, applied in powder coatings, reflective/signal coatings, polyester coatings, etc., to improve toughness and impact strength, good UV resistance, and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

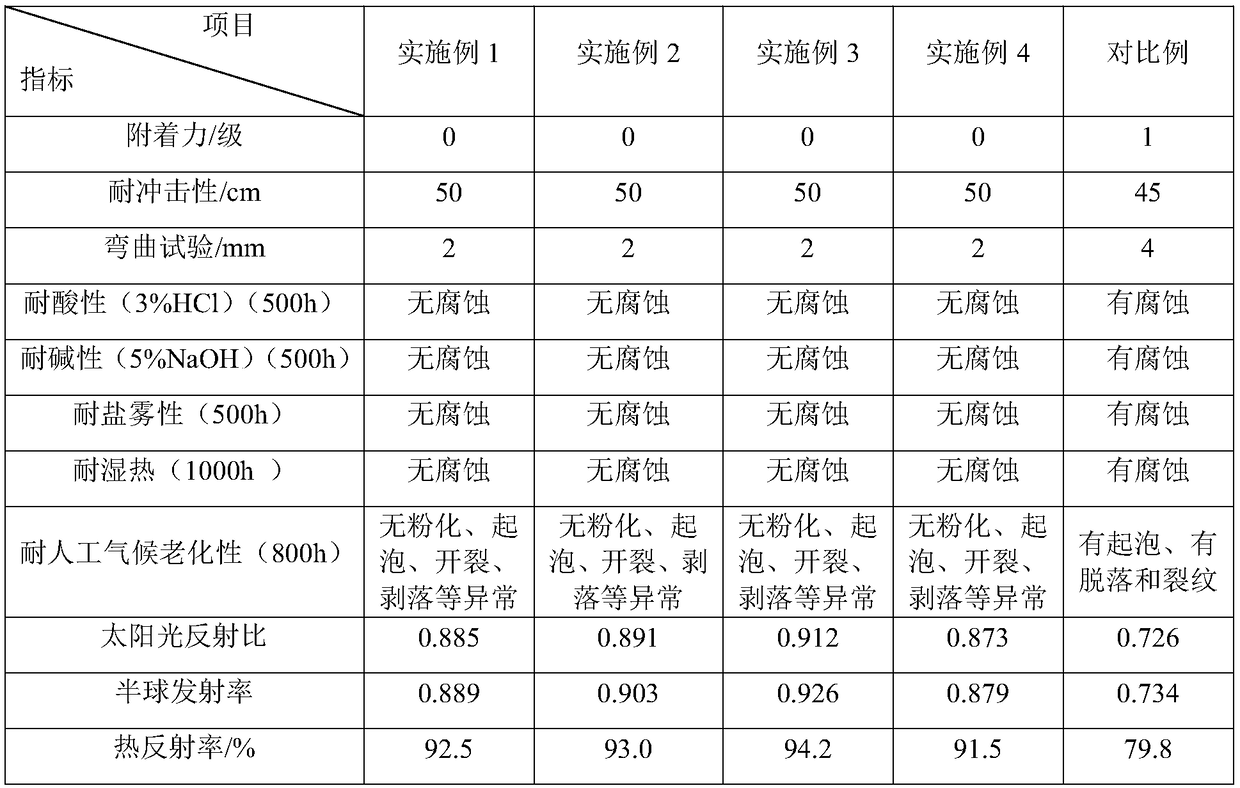

Examples

Embodiment 1

[0023] The preparation method of the anti-infrared nanometer titanium dioxide powder coating of the present invention comprises the following steps:

[0024] A. Put 42kg of nano-titanium dioxide, 18kg of nano-zinc oxide, 13kg of nano-zirconia, and 26kg of nano-ceramic powder into a high-speed mixer, stir at 2100rpm for 15min, and then add 1kg of coupling agent monoalkoxy-type titanate , high-speed stirring for 35min, to obtain the anti-infrared nano-titanium dioxide composite material;

[0025] B, with glycidyl acrylic resin 80kg, carboxyl polyester resin 80kg, 2-phenylimidazoline blocked isophorone diisocyanate 20kg, silicon dioxide adsorption polyacrylate 3.7kg, benzophenone 2kg, put Put it into a high-speed mixer, stir at 2100rpm for 15min, then add the anti-infrared nano-titanium dioxide composite material prepared in step A, and stir at a high speed for 35min to prepare the mixture of anti-infrared nano-titanium dioxide powder coating;

[0026] C. Put the mixture of the ...

Embodiment 2

[0029] Include the following steps:

[0030] A. Put 43kg of nano-titanium dioxide, 17kg of nano-zinc oxide, 14kg of nano-zirconia, and 24.7kg of nano-ceramic powder into a high-speed mixer, stir at 2100rpm for 15min, and then add coupling agent monoalkoxy titanate 1.3kg, high-speed stirring for 37min, to obtain an anti-infrared nano-titanium dioxide composite material; the nano-titanium dioxide is a rutile-type nano-titanium dioxide coated with 3% silica by mass percentage;

[0031]B, with glycidyl acrylic resin 71kg, carboxyl polyester resin 71kg, 2-phenylimidazoline blocked isophorone diisocyanate 15.8kg, silica adsorption polyacrylate 3.6kg, benzophenone 1.57kg , put it into a high-speed mixer, stir for 18min at a rotating speed of 2150rpm, then add the anti-infrared nano-titanium dioxide composite material prepared in step A, and stir at a high speed for 38min to obtain the mixture of anti-infrared nano-titanium dioxide powder coating;

[0032] C. Put the mixture of the a...

Embodiment 3

[0035] Include the following steps:

[0036] A. Put 41kg of nano-titanium dioxide, 18kg of nano-zinc oxide, 14kg of nano-zirconia, and 24.8kg of nano-ceramic powder into a high-speed mixer, stir at 2100rpm for 15min, and then add coupling agent monoalkoxy-type titanate 1.2kg, high-speed stirring for 38min, to prepare an anti-infrared nano-titanium dioxide composite material; the nano-titanium dioxide is a rutile-type nano-titanium dioxide coated with 3% silica by mass percentage;

[0037] B, with glycidyl acrylic resin 87.5kg, carboxyl polyester resin 90.6kg, 2-phenylimidazoline blocked isophorone diisocyanate 25kg, silica-adsorbed polyacrylate 5.6kg, benzophenone 3.75 kg, put into a high-speed mixer, and after stirring for 18min at a rotating speed of 2050rpm, add the anti-infrared nano-titanium dioxide composite material prepared in step A, and stir at a high speed for 38min to obtain the mixture of anti-infrared nano-titanium dioxide powder coating;

[0038] C. Put the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com