Insulation protection method for copper plated part

A technology for insulation protection and parts, applied in the field of insulation protection of copper-plated parts, can solve the problems of uneven transition zone between the plated surface and the non-plated surface, heating is required for dissolution and removal, and the metal wire cannot be reused, etc., to achieve good Protective effect, high stability, qualified effect of detection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] An insulation protection method for a chrome-plated copper-plated part of a shaft, comprising the following steps:

[0047] Step 1: Insulation Protection

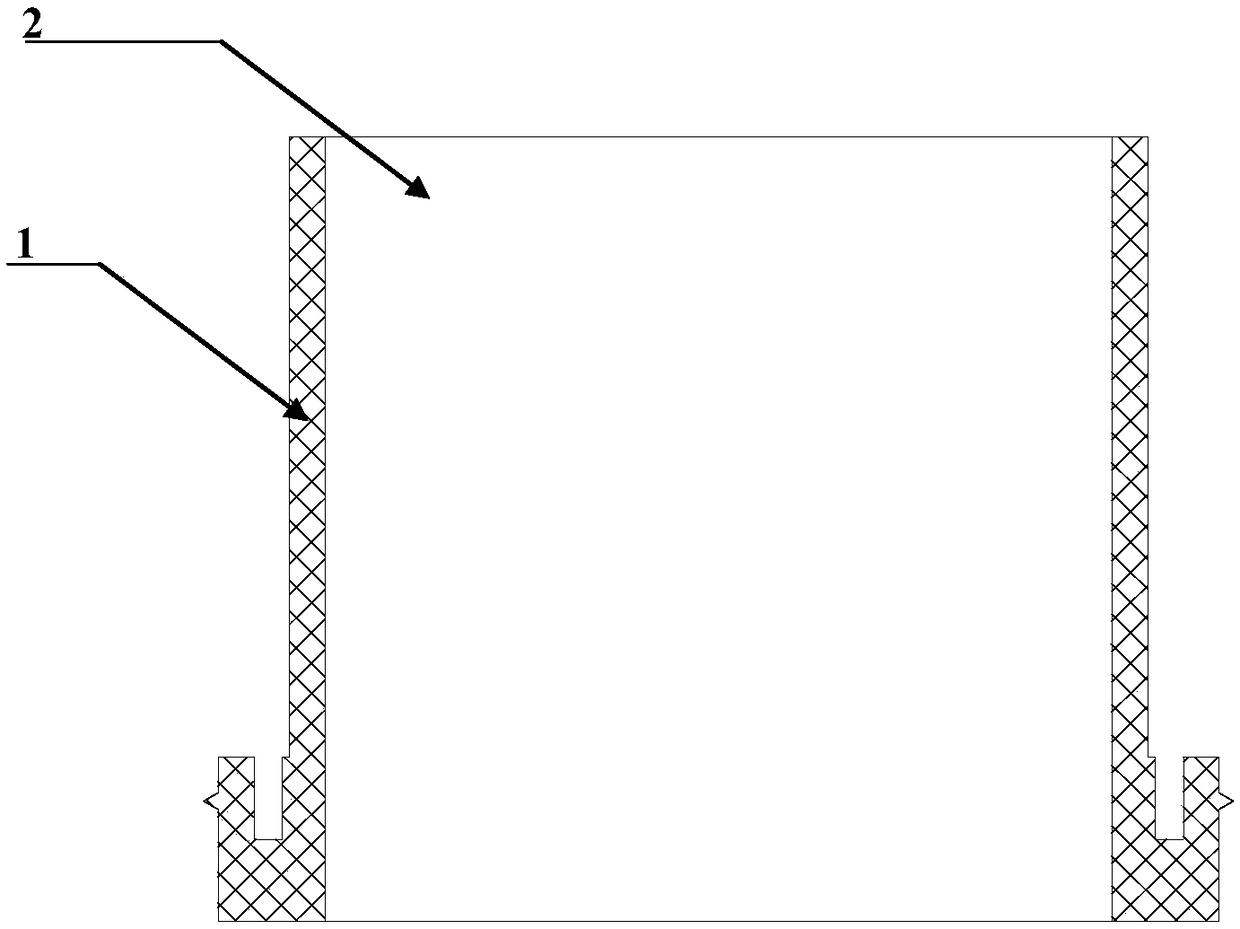

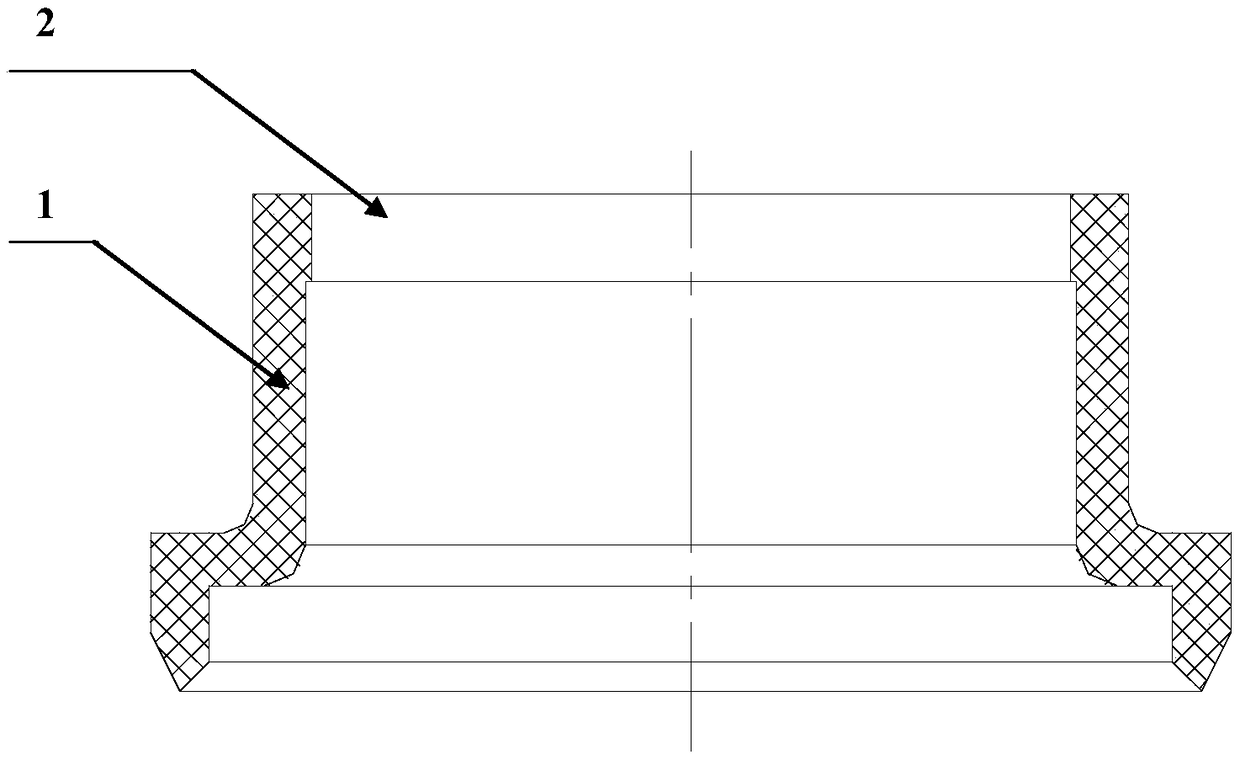

[0048] According to the shape of the non-copper-plated part 2 of the chrome-plated copper-plated part of the shaft to be processed, a special EPDM rubber 1 protective sleeve is designed, and it is set in the non-copper-plated area of the chrome-plated shaft. The structure diagram is shown in figure 1 ; Special EPDM rubber 1 protection plug is designed, which is set on the non-copper-plated part of the copper-plated part 2 except the teeth. The schematic diagram of its structure is shown in figure 2 , to get copper-plated parts.

[0049] The special EPDM rubber is corrosion-resistant to strong acid, strong alkali, cyanide, and plating solution containing hexavalent chromium, and its volume expansion rate is 0.2%; After the parts are batched, they will be severely deformed, their elasticity will decrease, and they...

Embodiment 2

[0068] A method for insulating and protecting the chrome-plated copper-plated parts of the shaft portion, the same as embodiment 1, the difference is that:

[0069] Step 5: Copper Plating

[0070] Place the pre-nickel-plated copper-plated parts in the plating bath, immerse in the cyanide bath for electroplating, and obtain electroplated copper parts; wherein, the temperature of the plating bath is 55°C, and the current density is 1.5A / dm 2 , the anode material is T 1 , the copper plating bath is a cyanide bath, and the composition and the content of each component included in the cyanide bath are: CuCN is 80g / L, NaCN (free) is 20g / L, NaOH is 15g / L, NaOH is 15g / L, Na 2 CO 3 40g / L, the balance is water;

Embodiment 3

[0072] A method for insulating and protecting the chrome-plated copper-plated parts of the shaft portion, the same as embodiment 1, the difference is that:

[0073] Step 6:

[0074] Place the copper-plated parts after electroplating copper in the passivation tank and immerse in the bath solution containing hexavalent chromium. 2 Cr 2 o 7 2H 2 O is 120g / L, H 2 SO 4 (ρ=1.84g / cm 3 ) is 5g / L, NaCl is 7g / L, and the rest is water. The passivation time is 5s;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com