Antibacterial hydrophobic finishing method for linen rayon interwoven fabric

A linen and fabric technology, applied in fiber treatment, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of bacterial invasion, affecting the health of users, easy to stick to dirt, etc., and achieve strong wash resistance, stability and relative Capacitance improvement, antibacterial performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

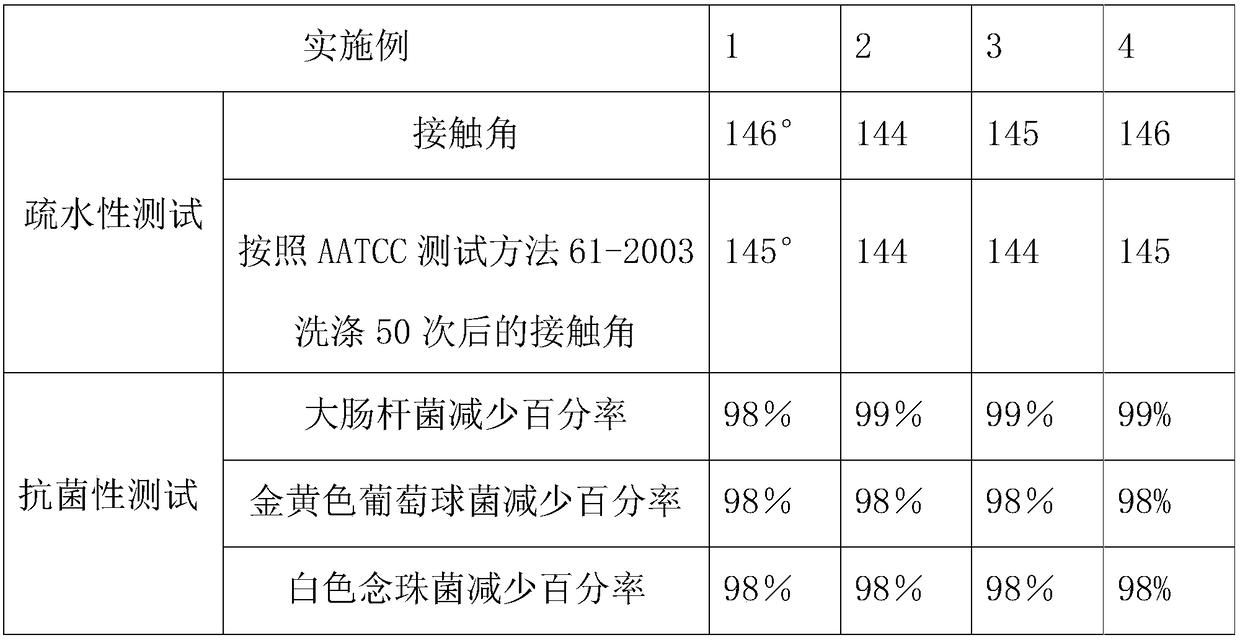

Examples

Embodiment 1

[0017] An antibacterial and hydrophobic finishing method for linen and rayon interwoven fabrics, comprising the steps of:

[0018] S1. After the surface of the linen and rayon interwoven fabric is ultrasonically cleaned with water and ethanol in sequence, it is then pad-finished in an aqueous solution containing polycarboxylic acid and sodium hypophosphite. The aqueous solution containing polycarboxylic acid and sodium hypophosphite , the content of polycarboxylic acid is 10wt%, and the content of sodium hypophosphite is 15wt%, and polycarboxylic acid is butane tetracarboxylic acid, two dipping two rollings, padding temperature is 80 ℃, and the excess rate is 150%, Then pre-drying at 80°C for 5 minutes to obtain a linen-rayon interwoven fabric containing -COOH groups on the surface;

[0019] S2. The linen rayon interwoven fabric containing -COOH groups on the surface obtained in step S1 contains organic antibacterial hectorite, cyclodextrin modified 3-glycidyl etheroxypropyl t...

Embodiment 2

[0022] An antibacterial and hydrophobic finishing method for linen and rayon interwoven fabrics, comprising the steps of:

[0023] S1. After the surface of the linen and rayon interwoven fabric is ultrasonically cleaned with water and ethanol in sequence, padding is carried out in an aqueous solution containing polycarboxylic acid and sodium hypophosphite, and the aqueous solution containing polycarboxylic acid and sodium hypophosphite is , the content of polycarboxylic acid is 30wt%, and the content of sodium hypophosphite is 5wt%, and polycarboxylic acid is citric acid, dips twice and rolls, and the padding temperature is 90 ℃, and the excess ratio is 80%, then in 90 Pre-baking at ℃ for 3 minutes to obtain a linen-rayon interwoven fabric containing -COOH groups on the surface;

[0024]S2. The linen rayon interwoven fabric containing -COOH groups on the surface obtained in step S1 contains organic antibacterial hectorite, cyclodextrin modified 3-glycidyl etheroxypropyl trialk...

Embodiment 3

[0027] An antibacterial and hydrophobic finishing method for linen and rayon interwoven fabrics, comprising the steps of:

[0028] S1. After the surface of the linen and rayon interwoven fabric is ultrasonically cleaned with water and ethanol in sequence, it is then pad-finished in an aqueous solution containing polycarboxylic acid and sodium hypophosphite. The aqueous solution containing polycarboxylic acid and sodium hypophosphite , the content of polycarboxylic acid is 20wt%, and the content of sodium hypophosphite is 10wt%, and polycarboxylic acid is butane tetracarboxylic acid, two dipping two rollings, padding temperature is 85 ℃, and the excess rate is 120%, Then pre-drying at 85°C for 4 minutes to obtain a linen-rayon interwoven fabric containing -COOH groups on the surface;

[0029] S2. The linen rayon interwoven fabric containing -COOH groups on the surface obtained in step S1 contains organic antibacterial hectorite, cyclodextrin modified 3-glycidyl etheroxypropyl t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com