Method for exciting conductive material to ignite by inputting and outputting electronic from side of circuit board

An electronic excitation, input and output technology, applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve problems such as high risk, poor contact, and bridge wires do not have welding melting power, so as to improve the safety and reliability of high temperature resistance and shock resistance. Accuracy, improving efficiency and reliability, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

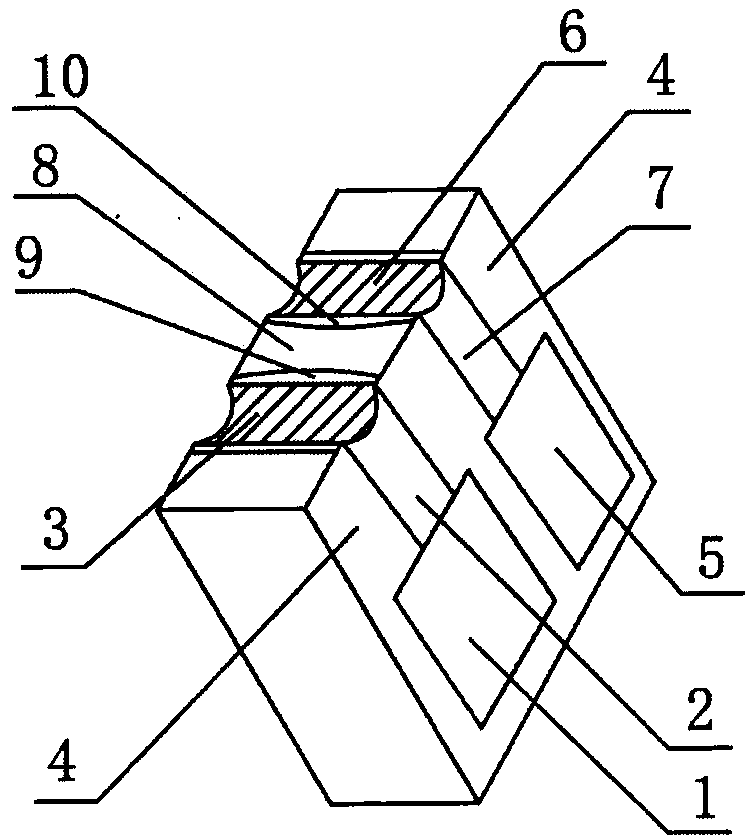

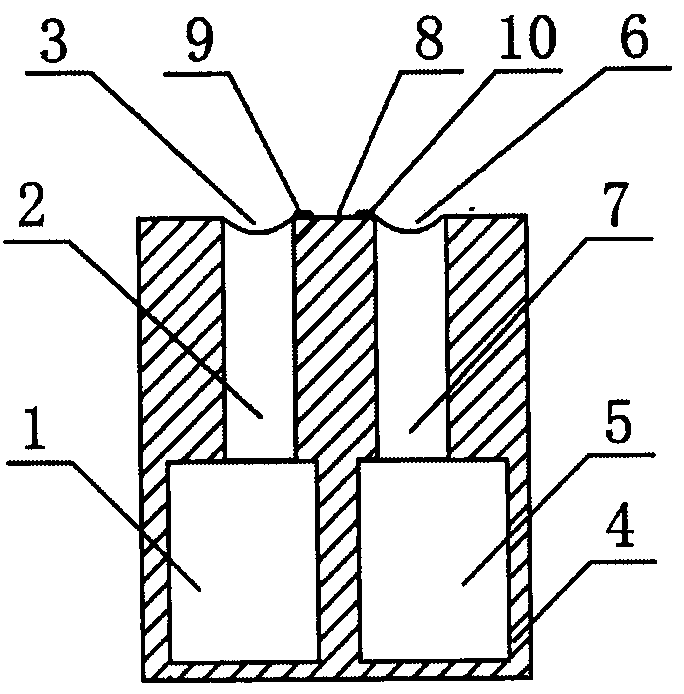

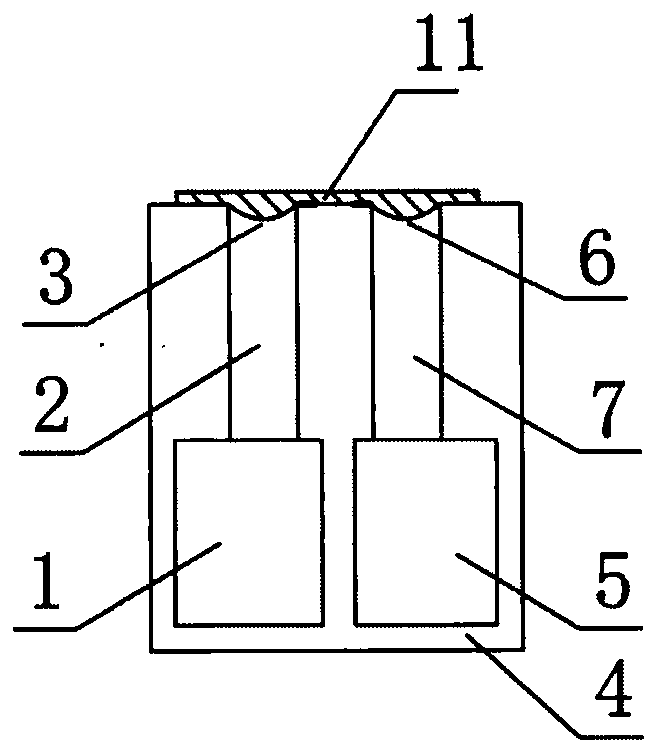

[0034] According to the invention, the input and output electrons on the side of the circuit board excite the ignition of the conductive material. The device involved in the method consists of a PCB circuit board, a first pad electrode 1, a first circuit 2, a first conductive hole 3, and an insulating area. 4. The second pad electrode 5, the second conductive hole 6, the second circuit 7, the discharge area 8, the first discharge terminal 9, the second discharge terminal 10 and the conductive material 11; the first pad electrode 1 passes through the first The circuit 2 is connected to the conductive hole 3, the first conductive hole 3 is connected to the first discharge terminal 9; the second pad electrode 5 is connected to the second conductive hole 6 through the second circuit 7, and the second conductive hole 6 is connected to the second discharge terminal 10 connection, a discharge area 8 is formed between the first discharge end 9 and the second discharge end 10, a conduct...

Embodiment 2

[0038] The device involved in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0039] The external centralized controller communicates and supplies power to the electronically excited detonator, and converts it into a communication signal and a supply voltage through the input circuit, and charges the energy storage capacitor. The switch sends an open signal, and the discharge switch outputs the capacitive energy through the circuit board to the side of the circuit board. Input and output electrons excite the conductive material ignition device Figure 6 , the first pad electrode 1, the second pad electrode 5 and the conductive material 11 welded to the PCB circuit board are at a 90° right angle; the conductive material 11 is coated between the first discharge area 9 and the second discharge area 10 It is graphene nano conductive coating;

[0040] Depend on Figure 4 and Figure 5 As show...

Embodiment 3

[0042] The device involved in this embodiment is carried out according to embodiment 1, and the specific operation is carried out according to the following steps:

[0043] The external centralized controller communicates and supplies power to the electronically excited detonator, and converts it into a communication signal and a supply voltage through the input circuit, and charges the energy storage capacitor. The switch sends an open signal, and the discharge switch outputs the capacitive energy through the circuit board to the side of the circuit board. Input and output electrons excite the conductive material ignition device Figure 6 , the first pad electrode 1, the second pad electrode 5 and the conductive material 11 welded to the PCB circuit board are at a 90° right angle; the conductive material 11 is coated between the first discharge area 9 and the second discharge area 10 Conductive coating for laser printer toner + nickel powder + nano graphite powder;

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com