Method for detecting starch in high-sugar meat floss

A detection method and technology of meat floss, applied in the direction of chemical analysis by titration method, can solve the problems of incomplete sugar washing and high test results, and achieve the effect of ensuring sugar washing effect, saving consumption and accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

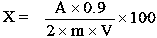

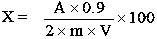

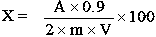

Image

Examples

Embodiment 1

[0030] Embodiment 1: adopt the inventive method to detect the content of starch in the meat floss powder that does not add starch of a certain brand:

[0031] First, prepare glucose standard solution: 1) Accurately weigh 1g of D-anhydrous glucose that has been dried at 98°C-100°C for 2 hours, add 5mL hydrochloric acid after dissolving in water, and dilute to 1000mL with water to obtain glucose standard solution; this solution Each milliliter is equivalent to 1.0 mg glucose;

[0032] 2) Calibration of alkaline copper tartrate solution: draw 5.00mL of alkaline copper tartrate A solution and 5.00mL of alkaline copper tartrate B solution, put them in a 150mL Erlenmeyer flask, add 10mL of water, add two glass beads, drop 9mL from the burette Glucose standard solution, controlled to be heated to boiling within 2 minutes, keep the solution in a boiling state, continue to drop glucose at a rate of one drop every two seconds, until the blue color of the solution just fades as the end p...

Embodiment 2

[0040] Embodiment 2, glucose standard solution preparation is the same as embodiment 1, adopts the inventive method to detect the content of starch in the dried meat floss powder of certain brand without adding starch:

[0041] Weigh 20g of the sample (accurate to 0.01g) into a 500ml beaker, add 92°C hot potassium hydroxide-ethanol solution, place it in a 90°C water bath, and obtain a degreasing sample after 1 hour in the water bath; use 85% of the 70°C heat Wash with ethanol suction filtration until the filtrate is clear, transfer the filter residue to a container, add 85% ethanol solution, heat in a boiling water bath for 20 minutes, then filter the mixture with suction, repeat this twice, and then use 85% 70°C heat Wash the precipitate with ethanol 6-8 times to obtain a sugar-free sample; take 1ml (about 15 drops) of the filtrate from the last suction filtration in a test tube, add 2 drops of Molish reagent, shake well, tilt the test tube, and slowly add concentrated Sulfur...

Embodiment 3

[0048] Embodiment 3, glucose standard solution preparation is the same as embodiment 1, adopts the inventive method to detect the content of starch in the meat floss powder of certain brand without adding starch:

[0049] Weigh 20g of the sample (accurate to 0.01g) into a 500ml beaker, add 88°C hot potassium hydroxide-ethanol solution, place it in a 90°C water bath, and obtain a degreasing sample after 2 hours in the water bath; use 85% of the 50°C hot Wash with ethanol suction filtration until the filtrate is clear, transfer the filter residue to a container, add 85% ethanol solution, heat in a boiling water bath for 30 minutes, then filter the mixture with suction, repeat this twice, and then use 85% 50°C heat Wash the precipitate with ethanol 6-8 times to obtain a sugar-free sample; take 1ml (about 15 drops) of the filtrate from the last suction filtration in a test tube, add 2 drops of Molish reagent, shake well, tilt the test tube, and slowly add concentrated Sulfuric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com