Amorphous sulfide solid electrolyte and preparation method thereof, lithium ion battery

A solid electrolyte and sulfide technology, which is used in the manufacture of non-aqueous electrolyte batteries, solid electrolytes, and electrolyte batteries, can solve the problems of Ge toxicity, high price, and high cost, and achieve the advantages of shortened ball milling time, environmental friendliness, and mild reaction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the amorphous sulfide solid electrolyte of the present invention comprises the following steps: under an inert atmosphere or vacuum condition, mix and ball mill a lithium source and other raw materials for 8-12 hours; the lithium source is lithium hydride or lithium hydride A mixed lithium source composed of at least one of LiCl, LiBr, and LiI.

[0034] The preparation method of the amorphous sulfide solid electrolyte of the present invention triggers a chain reaction through the micro-area alloying process during ball milling, and only needs a short-term ball milling reaction, which is different from the principle of obtaining an amorphous solid by long-term ball milling. In the invention, the amorphous solid can be obtained only by subjecting the raw materials to ball milling for a short time. Moreover, the method of the present invention can obtain an amorphous sulfide electrolyte material with excellent performance without the need for a la...

Embodiment 2

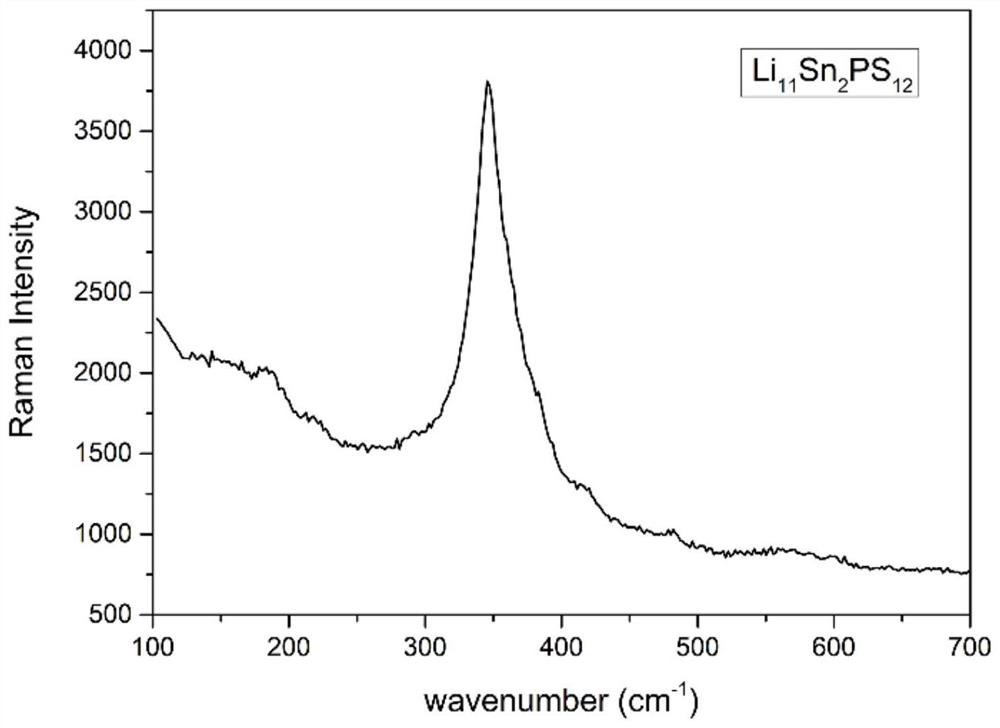

[0066] The amorphous sulfide solid electrolyte of this embodiment has the chemical formula shown below: Li 11 sn 2 P.S. 12 .

Embodiment 3

[0068] The amorphous sulfide solid electrolyte of this embodiment has the chemical formula shown below: Li 10.7 Si 2 P.S. 11.7 Cl 0.3 .

[0069] Example 4 of the amorphous sulfide solid electrolyte

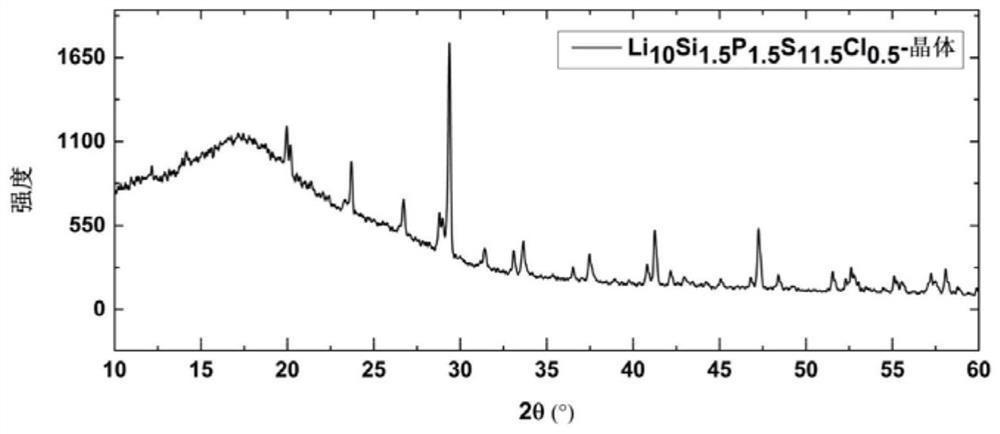

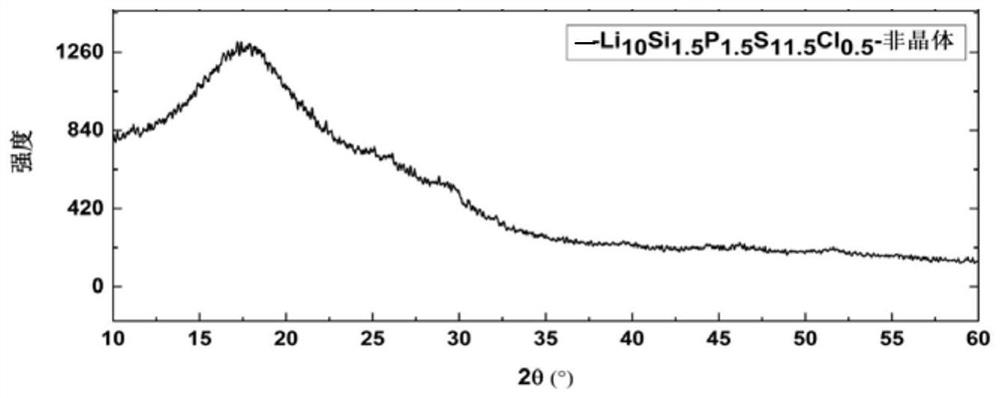

[0070] The amorphous sulfide solid electrolyte of this embodiment has the chemical formula shown below: Li 10 Si 1.5 P 1.5 S 11.5 Cl 0.5 .

[0071] Example 5 of the amorphous sulfide solid electrolyte

[0072] The amorphous sulfide solid electrolyte of this embodiment has the chemical formula shown below: Li 10.5 Si 1.5 P 1.5 S 12 .

[0073] Example 6 of Amorphous Sulfide Solid Electrolyte

[0074] The amorphous sulfide solid electrolyte of this embodiment has the chemical formula shown below: Li 10 sn 1.5 P 1.5 S 11.5 Cl 0.5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com