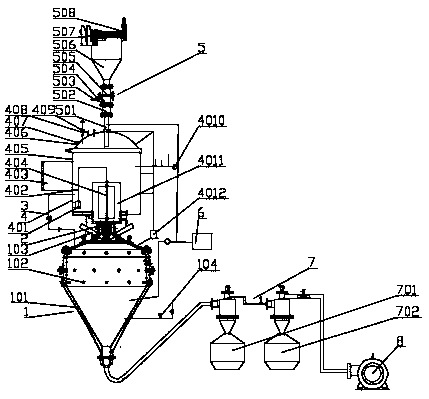

Plasma atomizing powdering device applicable to high-melting-point metal

A high-melting-point metal atomization powder-making technology, which is applied in the field of powder metallurgy equipment, can solve the problems of conveying speed blocking the diversion tube, affecting the fluidity of the melt, reducing the efficiency of metal atomization powder-making, etc., to meet the vacuum conditions, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

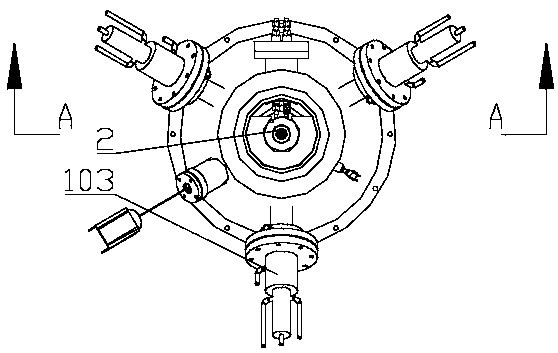

Method used

Image

Examples

Embodiment 2

[0105] Compared with Example 1, the plasma atomization powder making equipment suitable for high melting point metals in this example has the following differences:

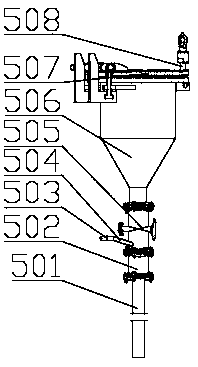

[0106] The feeding device 5 also includes a feeding mechanism, the buffer bucket 506 communicates with the feeding mechanism, and the feeding mechanism is a metal wire feeding mechanism 509 .

[0107] The turbine separation assembly includes three sets of turbine separation assemblies: a first-stage turbine separation assembly 701, a second-stage turbine separation assembly 702, and a third-stage turbine separation assembly 703, and the structures of the three sets of turbine separation assemblies are the same. For specific structures, see Figure 7~9 .

[0108] The working principle and use method of a plasma atomization powder making equipment suitable for high melting point metals in the present invention are as follows:

[0109] When it is necessary to put materials into the smelting furnace 4011 of the smel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com