Powder coating polyester resin for exhaust pipe of motor vehicle and preparation method thereof

A powder coating and polyester resin technology, applied in powder coatings, fireproof coatings, polyester coatings, etc., can solve the problem that the temperature and weather resistance cannot meet the needs of actual use, achieve efficient esterification combination, improve efficiency, strong rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

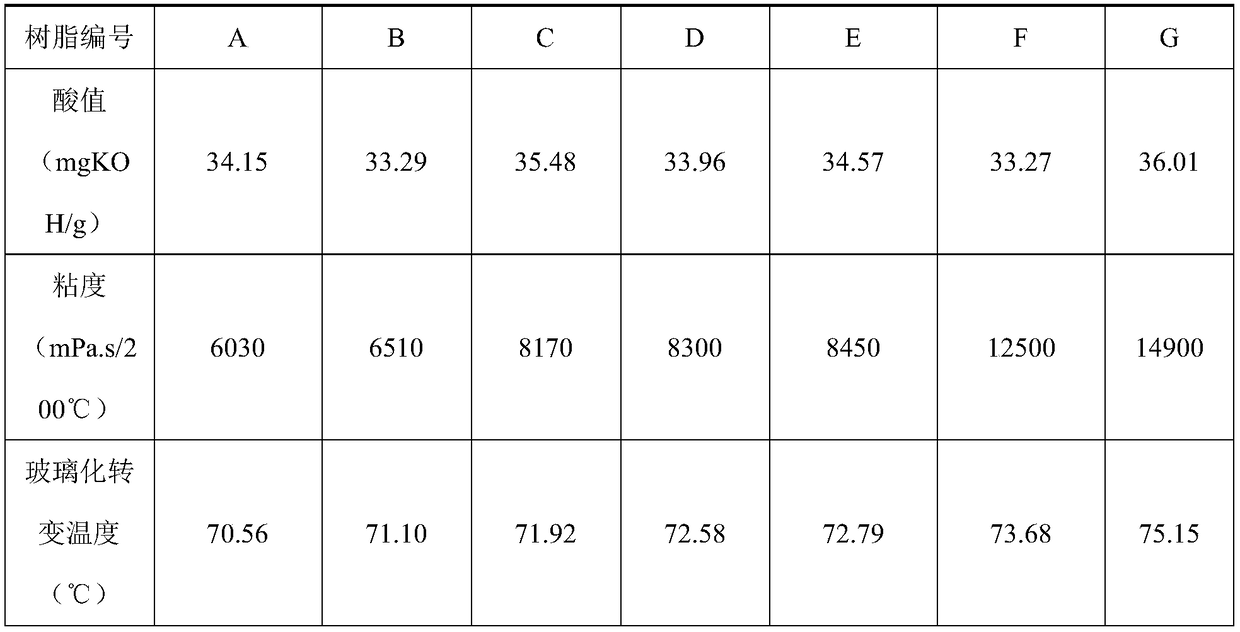

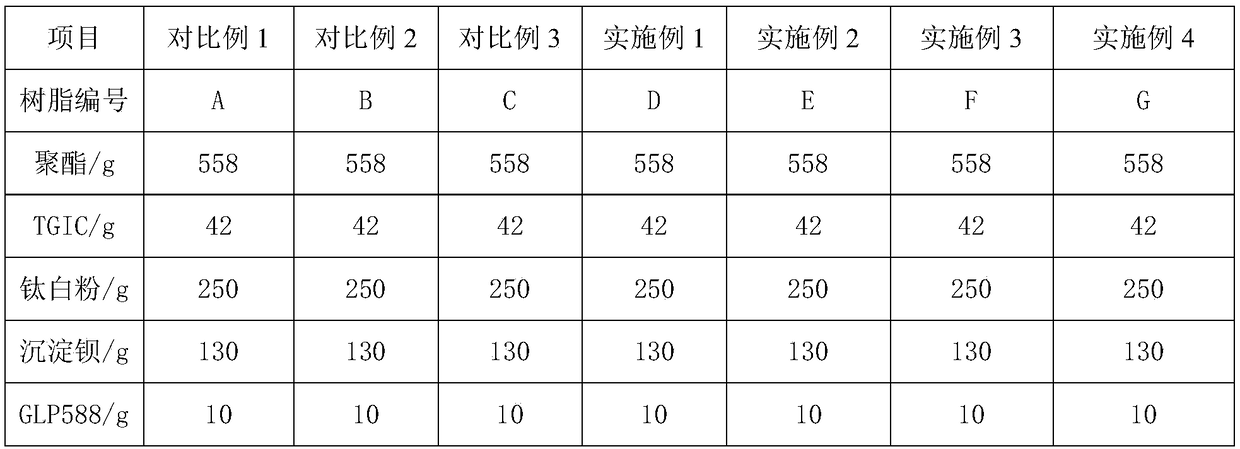

Embodiment 1

[0057] A kind of powder coating polyester resin for motor vehicle exhaust pipe that the present invention proposes, its raw material comprises by weight: 54.1 parts of terephthalic acid, 32.7 parts of neopentyl glycol, 1,3-bis(2-hydroxyethyl) 11.5 parts of -5,5-dimethylhydantoin, 1.6 parts of Cyclo, 84 parts of isophthalic acid, 4.7 parts of cyclohexanedicarboxylic acid, 0.1 parts of monobutyltin oxide, 0.1 parts of triphenyl phosphite, curing Accelerator 1.5 parts.

[0058] The present invention also proposes a method for preparing a powder coating polyester resin for motor vehicle exhaust pipes, comprising the steps of:

[0059] S1. Feeding: Put neopentyl glycol into the reaction kettle, stir, heat, and melt until the temperature of the material is greater than 60°C, and slowly add terephthalic acid, Cyclo and monobutyltin oxide;

[0060] S2. Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤102°C, and the temperatur...

Embodiment 2

[0065] A kind of powder coating polyester resin for motor vehicle exhaust pipe that the present invention proposes, its raw material comprises by weight: 51.5 parts of terephthalic acid, 26.3 parts of neopentyl glycol, 1,3-bis(2-hydroxyethyl) 20.4 parts of -5,5-dimethylhydantoin, 1.5 parts of Cyclo, 8.0 parts of isophthalic acid, 4.4 parts of cyclohexanedicarboxylic acid, 0.1 parts of monobutyl tin oxide, 0.1 parts of triphenyl phosphite, curing Accelerator 1.5 parts.

[0066] The present invention also proposes a method for preparing a powder coating polyester resin for motor vehicle exhaust pipes, comprising the steps of:

[0067] S1. Feeding: Put neopentyl glycol into the reaction kettle, stir, heat, and melt until the temperature of the material is greater than 60°C, and slowly add terephthalic acid, branched components and catalysts;

[0068] S2. Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤102°C, and the tem...

Embodiment 3

[0073] The present invention proposes a powder coating polyester resin for motor vehicle exhaust pipes, which has the following raw materials in parts by mass: 53.9 parts of terephthalic acid, 31.8 parts of neopentyl glycol, 1,3-bis(2-hydroxyethyl)- 11.4 parts of 5,5-dimethylhydantoin, 2.6 parts of Cyclic acid, 8.3 parts of isophthalic acid, 4.7 parts of cyclohexanedicarboxylic acid, 0.1 part of monobutyltin oxide, 0.1 part of triphenyl phosphite, curing accelerator 1.5 parts.

[0074] The present invention proposes also a kind of preparation method of powder coating polyester resin for motor vehicle exhaust pipe, comprises the following steps:

[0075] S1. Feeding: Put neopentyl glycol into the reaction kettle, stir, heat, and melt until the temperature of the material is greater than 60°C, and slowly add terephthalic acid, Cyclo and monobutyltin oxide;

[0076] S2. Heating esterification: During esterification, the temperature at the top of the tower is controlled to be ≤10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com