Metallurgical zinc-containing dust removal treatment and utilization device and method

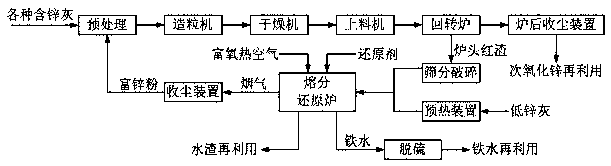

A dust collector and zinc ash technology, applied in the direction of improving process efficiency, can solve the problems of low dezincification rate, high treatment cost, and inability to handle dust removal ash, etc., to improve the quality of molten iron, make full use of waste heat, and reduce heat loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

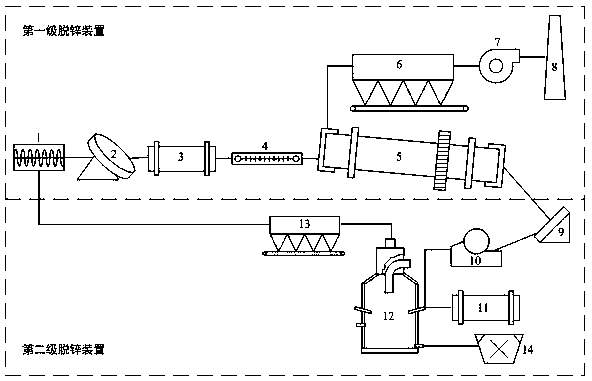

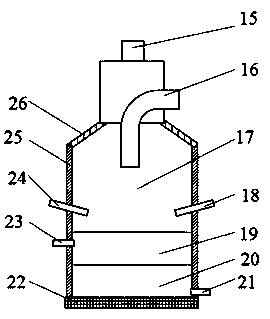

[0052] The zinc-containing dust ash with 4-6% zinc content is pre-batched in the zinc-containing dust ash pretreatment bin 1, and then granulated with a disc granulator 2 to a particle size of 3-5 mm, and then sent to a dryer 3 for drying. The dried granules are fed into the rotary furnace 5 for reduction and oxidation through the feeder 4 for the first dezincification. The operating temperature of the rotary furnace is 1100-1150°C; the volatilized dust containing more than 55% zinc comes out from the furnace tail and passes through the first dezincification. The dust collection device 6 is collected into the next section for reuse; the high-temperature red slag with a zinc content of less than 1% in the furnace head and a temperature of 800-1000 ° C is subjected to thermal screening and crushing by the red slag screener 9 and the red slag crusher 10, Broken until the particles are less than 8mm; the high-temperature particles at 600 degrees Celsius after being broken are trans...

Embodiment 2

[0056] The zinc-containing dust with 6-8% zinc content is pre-batched in the zinc-containing dust pretreatment system, and then granulated by a tooth stirring granulator, the particle size is 3-5 mm, and then it is dried in a dryer and fed through The machine puts the dried particles into the rotary furnace for reduction and oxidation for the first dezincification. The operating temperature of the rotary furnace is 1150-1200 °C; the dust containing more than 55% zinc comes out of the furnace tail and is collected by the first dust collector into the next section. Reuse; high-temperature red slag with a zinc content of less than 1% in the furnace head and a temperature of 800-1000 °C is subjected to hot screening and crushing, and the particles are crushed to less than 8 mm; The silo is sprayed with a spray gun into the melting reduction furnace of equipment 12 to carry out the second dezincification; the temperature in the melting reduction furnace is controlled at 1400-1450 de...

Embodiment 3

[0060] The zinc-containing dust with 8-10% zinc content is pre-batched in the zinc-containing dust pretreatment bin, and then granulated by a tooth stirring granulator with a particle size of 3-5 mm, and then dried in a dryer, and fed through The machine puts the dried particles into the rotary furnace for reduction and oxidation for the first dezincification. The operating temperature of the rotary furnace is 1150-1200 °C; the dust containing more than 55% zinc comes out of the furnace tail and is collected by the first dust collector into the next section. Reuse; high-temperature red slag at 800-1000°C with a zinc content of less than 1% in the furnace head is subjected to hot screening and crushing until the particles are less than 8mm; The silo is sprayed into the melting reduction furnace with a spray gun for the second dezincification; the temperature in the melting reduction furnace is controlled at 1400-1450 degrees Celsius; at the same time, blue charcoal powder is spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com