Dry contact flat plate heat pipe floor radiation heating method and heating system

A flat plate heat pipe and radiant heating technology, applied in hot water central heating systems, heating systems, indirect heat exchangers, etc., can solve the problems of low stability and reliability, poor heat exchange capacity, etc. The effect of increasing the speed and reducing the flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

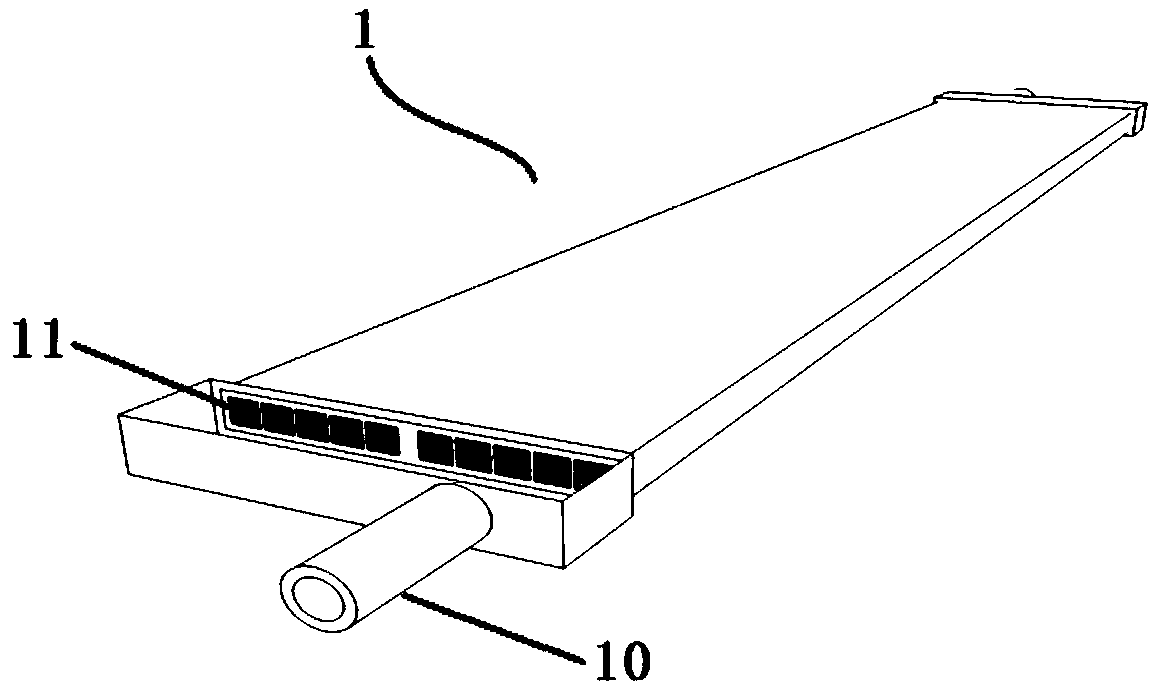

[0040] Such as figure 1 , the present embodiment is for heating a small-area space, and the flat water tank pipe 1 is preferably used as the hot water supply pipe. The capillary micro-groove improves the heat exchange efficiency of the water supply pipe.

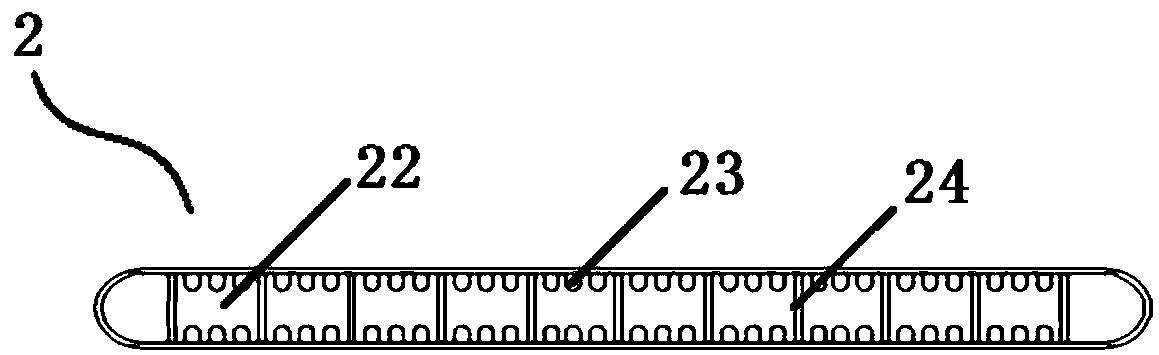

[0041] Such as figure 2 , 4 , 5, the heating system of the present invention adopts the micro heat pipe array 2 as the radiating pipe, and the micro heat pipe array 2 is a plate structure with a plurality of independent micro through holes 22 arranged side by side through welding or stamping or extrusion of metal materials body, the micro-toothed fins 23 are provided on the side walls of the micro-through holes 22, a large number of capillary micro-groove structures are provided on the micro-through-hole wall 24, and the two ends of the micro-heat pipe array 2 are sealed and packaged; the present invention fills the micro-heat pipe array 2 In the working environment of the present invention, a condensing agent capable of...

Embodiment 2

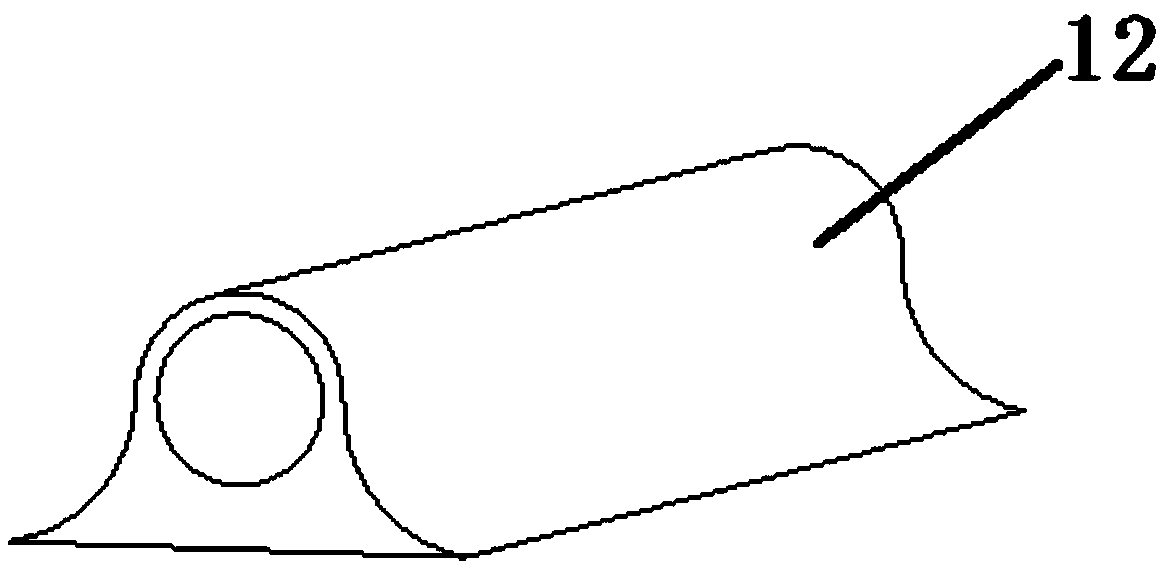

[0046] This embodiment provides heating for a large area of space, such as image 3 As shown, the airfoil pipe 12 is used as the hot water supply pipe. The pipe of the airfoil pipe 12 is thick, which reduces the flow resistance of the working fluid and improves the circulation efficiency of the working fluid. The special shape of the airfoil pipe 12 can be well integrated with micro The heat pipe array is bonded, and compared with the traditional round pipe, the heat exchange area is increased and the heat exchange efficiency is improved. The heat dissipation section of the micro heat pipe array 2 forms an included angle of 4.5° with the horizontal ground, and other structures are similar to those in Embodiment 1.

Embodiment 3

[0048] Compared with Embodiment 1, this embodiment has two pads 6 of the same height, the micro heat pipe array 2 is placed horizontally, and microchannels with capillary structure are arranged on the wall surface, and the reflux circulation of the condensing agent is assisted by its capillary adsorption force. Other structures and implementations Example 1 is similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com