Oligomerization process using zeolites and silica-alumina containing catalysts

A technology of silica and alumina, which is applied in the field of gas oil, can solve expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Example 1: Preparation of silica-alumina based catalyst C1

[0076] Catalyst C1 was prepared by extruding binder-free silica-alumina SA1. Catalyst C1 thus corresponds in this example to shaped silica-alumina SA1.

[0077] Alumina hydrate was prepared according to the teaching of patent US 3 124 418 . After filtration, the freshly prepared precipitate was mixed with a silicic acid solution prepared by exchange on a decationization resin (Amberlyst).

[0078] Adjust the ratio of the two solutions so as to achieve 70% Al on the final support 2 o 3 -30% SiO2 2 composition. The mixture was rapidly homogenized in the presence of nitric acid in a commercial colloid mill such that the nitric acid content of the suspension leaving the mill was 8% relative to the silica-alumina mixed solids. Next, the suspension is routinely dried in an atomiser at typically 300°C to 60°C. The powder thus prepared was shaped in a Z-arm in the presence of 3% nitric acid relative to the an...

Embodiment 2

[0079] Example 2: Preparation of Zeolite Catalyst C2 Based on Zeolite ZSM-5

[0080] Boehmite powder and zeolite ZSM-5 powder (CBV8014 supplied by Zeolyst) were introduced into the mixer and acidified water was added with mixing at 50 rpm in a batch mixer equipped with a Z-arm. The acidic mixing was continued for 30 minutes. The neutralization step was carried out by adding the ammonia solution and mixing for 15 minutes. The resulting paste was extruded through a piston extruder at a speed of 10 mm / min.

[0081] After extrusion, the sticks were dried overnight at 80°C. Then use a flow rate of 1NL / h / g cat The obtained dry solid was calcined at 600° C. for 2 hours in humid air containing 4% by weight of water.

[0082] The catalyst thus obtained comprises 60% by weight of zeolite ZSM-5 and 40% by weight of alumina binder, the percentages by weight expressed relative to the total mass of the catalyst.

Embodiment 3

[0083] Embodiment 3 (according to the present invention)

[0084] A feed consisting of 50% by weight of the C4 fraction and 50% by weight of the C5-C6 fraction, all obtained from the FCC unit, was provided. The composition of the feedstock is listed in Table 1.

[0085] raw material compound weight% butane 19.6 Butene 30.6 Pentane 15.9 Pentene 19.8 Hexane 7.9 Hexene 5.7 total dienes 0.5

[0086] Table 1: Composition of starting materials.

[0087] The feedstock is first purified to achieve a total nitrogen content of less than 0.5 ppm. This feedstock is then sent over the silica-alumina based catalyst C1 prepared in Example 1 in the first oligomerization step; the total effluent from this step is sent to Example 1 in the second oligomerization step 2 prepared on the zeolite catalyst C2.

[0088] The pressure at the inlet of the oligomerization unit was set at 6 MPa.

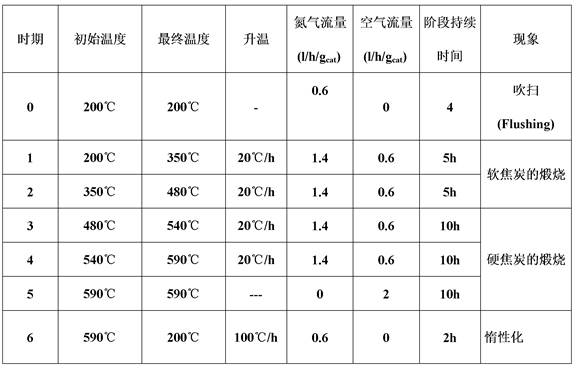

[0089] The mode of operation is the same in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com