Chocolate coating cheese and preparation method thereof

A chocolate coating and chocolate technology, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of not being able to provide, and achieve the effects of being easy to carry and eat, improving flavor characteristics and texture, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

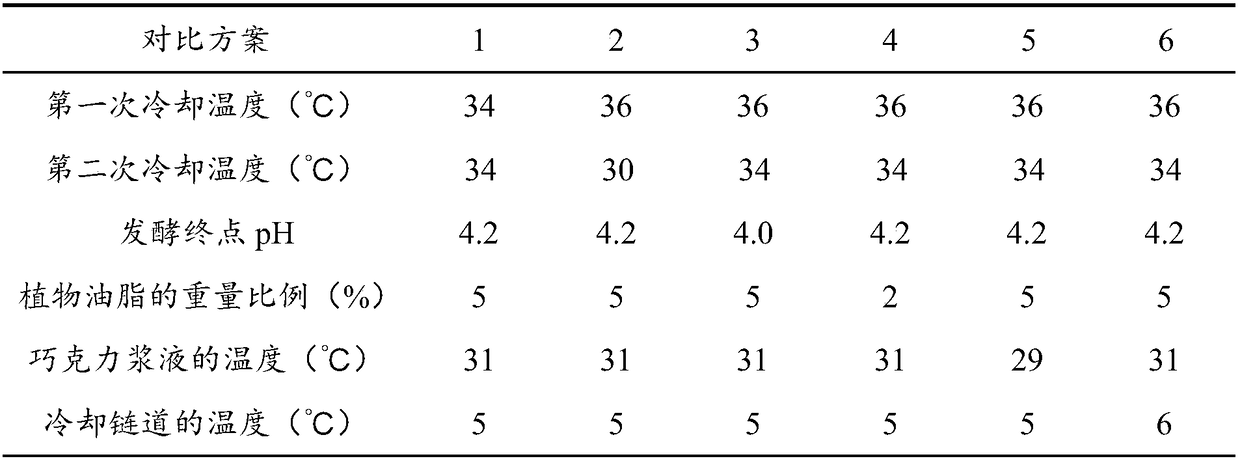

[0022] In a specific embodiment, a method for preparing chocolate coated cheese is provided. The method includes the following steps:

[0023] (1) After preheating the standardized raw milk, add 7-10% of the raw milk weight of sweet substances, 0.1-2% dietary fiber, 0.3-15% milk protein, stir and mix, homogenize and sterilize 、After the first cooling, inoculate the starter for fermentation, add the rennet curd after the second cooling, cut, drain the whey, and pack to obtain cheese, and refrigerate at 0~4℃ for later use;

[0024] (2) Raise the cocoa mass to 30~49℃ for the first time in water so as to slowly dissolve and stir it evenly. Add 3~5% of the weight of the cocoa mass of vegetable oil, after adjusting the temperature, the temperature will be 30~31 ℃ chocolate slurry;

[0025] (3) The chocolate slurry of step (2) is heated to 40-45° C. with water for the second time, so that it is evenly coated on the cheese of step (1), and it is obtained after cooling and aseptic packaging....

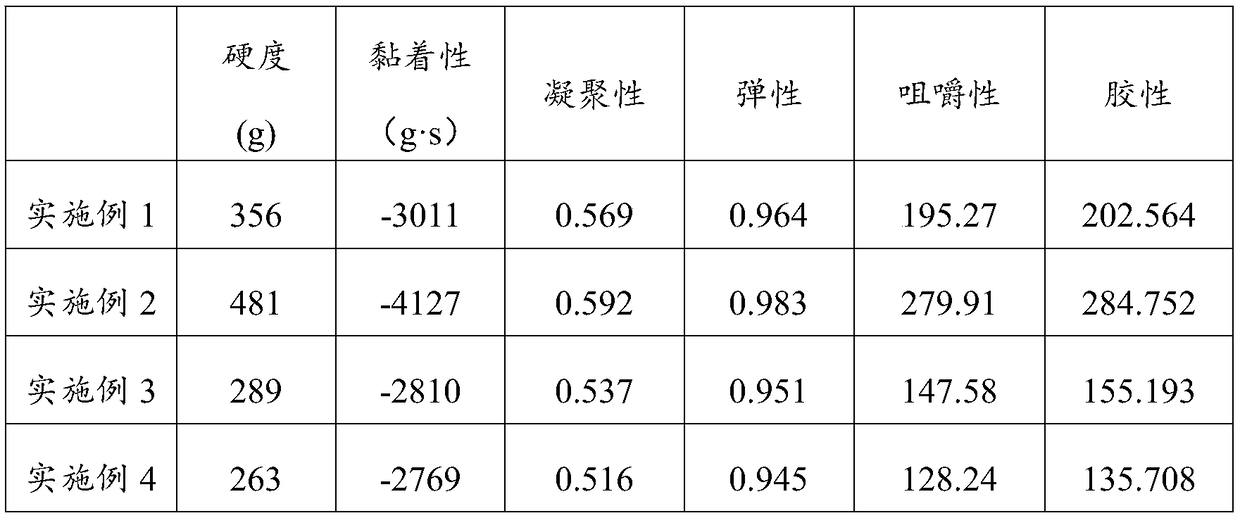

Embodiment 1

[0040] A method for preparing chocolate coated cheese includes the following steps:

[0041] (1) Preparation of cheese: Standardize raw milk, preheat it to 50°C, add 10% of the raw milk weight of sweet substances, 2% polydextrose, and 10% whey protein concentrate, stir for 20 minutes, mix evenly, and fully dissolve it Homogenization, the homogenization temperature is 65°C, and the pressure is 20 MPa. The first-stage homogenization pressure is 5 MPa and the second-stage homogenization pressure is 16 MPa. The homogenized material is sterilized at 98℃ / 5min, then cooled to 36℃, inoculated with 200U / ton milk feed liquid starter Lactococcus lactis subsp. crema, and fermented for 2h, the second cooling temperature is 34℃, add the material liquid The rennet of 0.001% by weight was allowed to stand for 2 hours until the end pH was 4.2 to obtain a curd mass. Cut the curd block into a volume of 0.5cm 3 Let stand for 10min, warm to 50℃ and keep for 30min to drain the whey, rinse the curd wi...

Embodiment 2

[0045] A method for preparing chocolate coated cheese includes the following steps:

[0046] (1) Preparation of cheese: standardize raw milk, preheat it to 60°C, add 9% of the raw milk weight sweet substance, 0.1% inulin, 15% milk protein concentrate, stir for 20 minutes, mix well, and dissolve thoroughly. The homogenization temperature is 75°C, the pressure is 18MPa, the first-stage homogenization pressure is 2MPa, and the second-stage homogenization pressure is 16MPa. The homogenized material is sterilized at 100℃ / 5min, then cooled to 38℃, inoculated with 100U / ton milk feed liquid starter Lactococcus lactis subsp. lactis, and fermented for 1h. The second cooling temperature is 35℃, add the feed liquid The rennet of 0.0008% by weight is fermented for 1.5 hours to the end pH value of 4.3 to obtain the rennet. Cut the curd block into a volume of 0.5cm 3 Let it stand for 5min, heat it up to 45℃ and keep it for 20min to drain the whey, rinse the curd with purified water, collect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com