High temperature resistant hydraulic adhesive material and mortar made from it

A technology of high temperature resistance and hydraulic adhesive, which is applied in the field of building materials, can solve the problems of reduced strength of building materials and damage to hardened slurry systems, and achieve the effects of reducing the possibility of carbonization, ensuring stability, and avoiding metastable phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

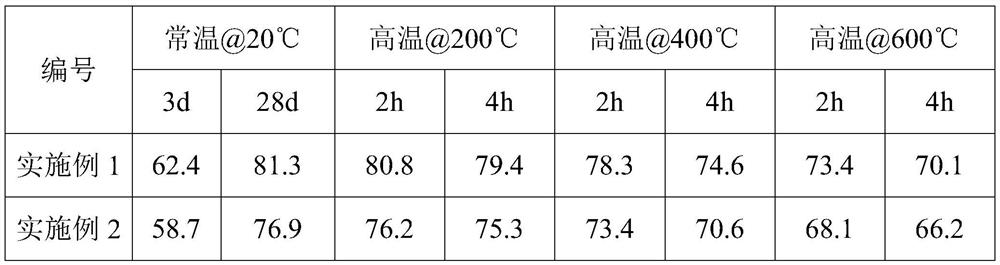

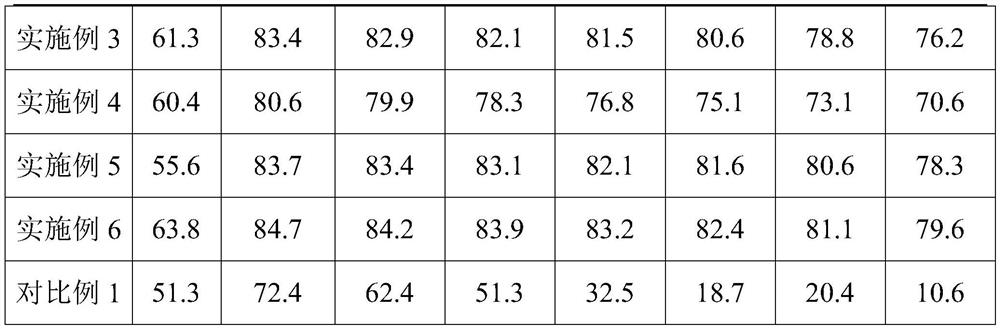

Examples

Embodiment 1

[0031] A mortar made of high-temperature-resistant hydraulic adhesive material is characterized in that it is obtained by uniformly mixing the following raw materials in weight proportions, including:

[0032] High temperature resistant hydraulic adhesive 400 parts

[0033] Quartz sand 350 parts

[0034] Mineral powder 100 parts

[0035] Dolomite powder 150 parts

[0036] Polycarboxylate high-performance water reducer 1 part

[0037] Sodium gluconate 0.5 parts

[0038] Among them, in the high-temperature-resistant hydraulic adhesive material, the content of tricalcium silicate is 40%, the content of dicalcium silicate is 10%, the content of amorphous silica is 50%, and the content of quartz sand is 20-100 mesh.

Embodiment 2

[0040] A mortar made of high-temperature-resistant hydraulic adhesive material is characterized in that it is obtained by uniformly mixing the following raw materials in weight proportions, including:

[0041] High temperature resistant hydraulic adhesive 400 parts

[0042] Quartz sand 350 parts

[0043] Metakaolin 100 parts

[0044] Dolomite powder 150 parts

[0045] Polycarboxylate high-performance water reducer 1 part

[0046] Sodium gluconate 0.5 parts

[0047] Among them, in the high-temperature-resistant hydraulic adhesive material, the content of tricalcium silicate is 40%, the content of dicalcium silicate is 10%, the content of amorphous silica is 50%, and the content of quartz sand is 20-100 mesh.

Embodiment 3

[0049] High temperature resistant hydraulic adhesive 400 parts

[0050] Quartz sand 350 parts

[0051] Mineral powder 100 parts

[0052] Talc powder 150 parts

[0053] Polycarboxylate high-performance water reducer 1 part

[0054] Sodium gluconate 0.5 parts

[0055] Among them, in the high-temperature-resistant hydraulic adhesive material, the content of tricalcium silicate is 40%, the content of dicalcium silicate is 10%, the content of amorphous silica is 50%, and the content of quartz sand is 20-100 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com