An automobile shock absorber guide

A technology of automobile shock absorbers and guides, which is applied in the field of alloy steel materials, can solve the problems of uncontrollable spring rebound, loss of tire grip and tracking performance, etc., and achieve the effect of high strength and rigidity, and excellent compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

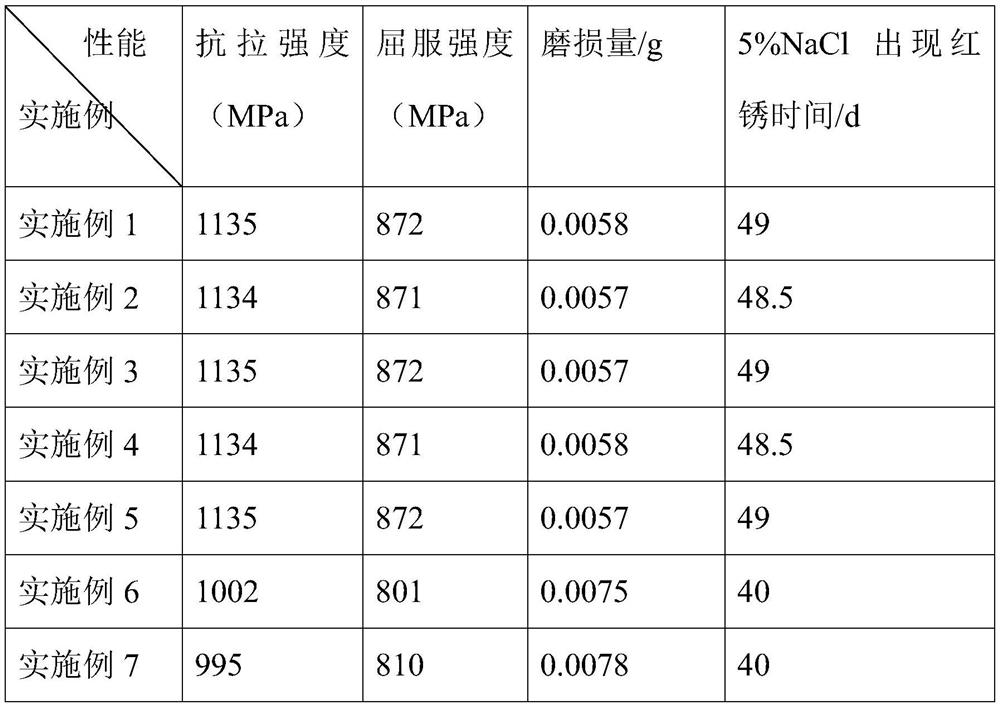

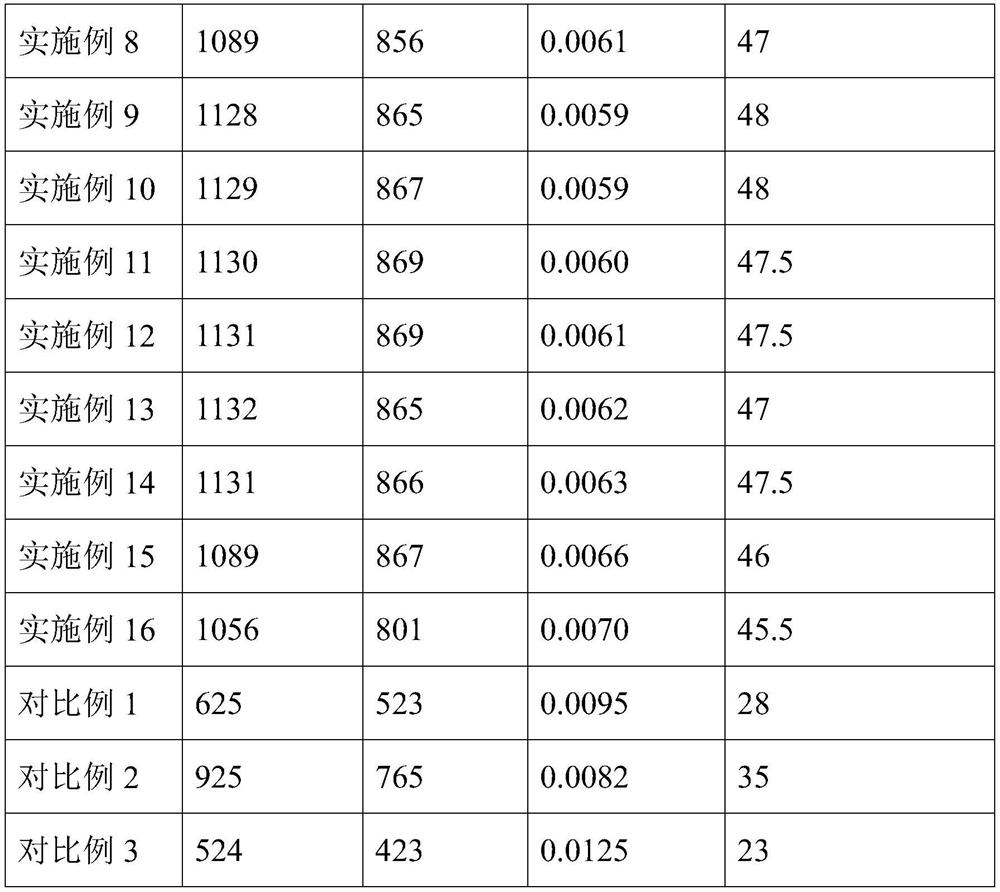

Examples

Embodiment 1

[0029] Raw material mixing: After mixing the foamed steel composition with calcium carbonate, add absolute ethanol, and mix them together in a mixer to form a powder; wherein, the foamed steel is composed of the following components by mass percentage: C: 0.02% , Cr: 15%, Mo: 2.5%, Mn: 0.26%, Si: 0.32%, Ti: 0.28%, rosin: 0.36%, Ru: 0.035%, and the balance is Fe; the Ru surface is coated with poly protein layer, the thickness of the polyprotein layer is 2.3nm, and the Ru is added in the form of its single nucleus; the quality of the calcium carbonate is 3.2% of the foamed steel quality; the powder particle diameter of the calcium carbonate is 1.8 mm; the quality of the dehydrated alcohol is 2.8% of the foamed steel quality;

[0030] Compression forming: placing the powder in the compacting mold, and demoulding the foam steel billet after compacting with a unidirectional loading hydraulic press; the compression forming step also includes adding NdBaMgO seed crystals whose mass i...

Embodiment 2

[0035] Raw material mixing: After mixing the foamed steel composition with calcium carbonate, add absolute ethanol, and mix them together in a mixer to form a powder; wherein, the foamed steel is composed of the following components by mass percentage: C: 0.022% , Cr: 15.2%, Mo: 2.7%, Mn: 0.27%, Si: 0.35%, Ti: 0.30%, rosin: 0.39%, Ru: 0.038%, and the balance is Fe; the Ru surface is coated with poly Protein layer, the thickness of the polyprotein layer is 2.35nm, and the Ru is added in the form of its binuclei; the quality of the calcium carbonate is 3.3% of the foamed steel quality; the powder particle diameter of the calcium carbonate is 1.9mm ; The quality of the dehydrated alcohol is 2.9% of the foamed steel quality;

[0036] Compression forming: placing the powder in the compacting mold, and demoulding the foam steel billet after compacting with a unidirectional loading hydraulic press; the compression forming step also includes adding NdBaMgO seed crystals whose mass is ...

Embodiment 3

[0041] Raw material mixing: After mixing the foamed steel composition with calcium carbonate, add absolute ethanol, and mix them together in a mixer to form a powder; wherein, the foamed steel is composed of the following components by mass percentage: C: 0.025% , Cr: 15.5%, Mo: 2.9%, Mn: 0.29%, Si: 0.38%, Ti: 0.34%, rosin: 0.42%, Ru: 0.043%, and the balance is Fe; the Ru surface is coated with poly protein layer, the thickness of the polyprotein layer is 2.4nm, and the Ru is added in two forms of mononuclear and binuclear; the quality of the calcium carbonate is 3.35% of the foamed steel quality; the powder particles of the calcium carbonate Diameter is 2mm; The quality of described dehydrated alcohol is 3% of foamed steel quality;

[0042] Compression forming: placing the powder in the compacting mold, and demoulding the foam steel billet after compacting with a unidirectional loading hydraulic press; the compression forming step also includes adding NdBaMgO seed crystals wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com