Neodymium-iron-boron magnetic material and preparation method

A magnetic material, neodymium-iron-boron technology, applied in the direction of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of low Curie temperature, increase the Curie temperature, increase the coercive force, and improve production The effect on quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

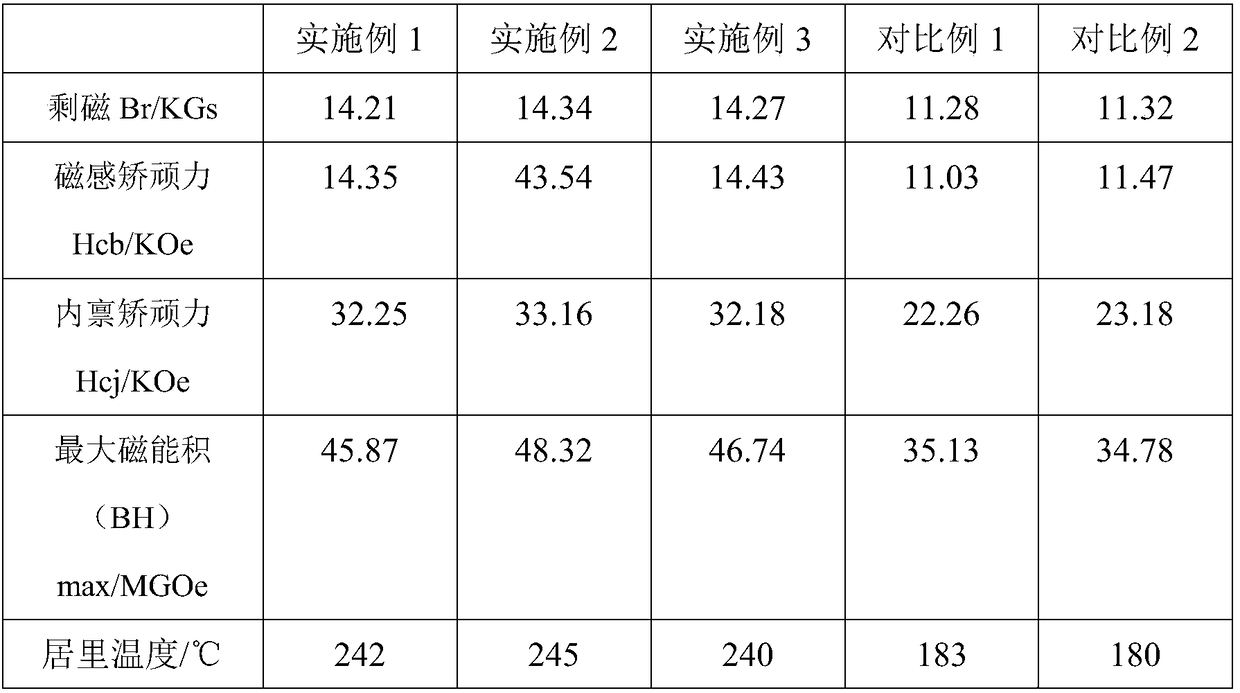

Examples

Embodiment 1

[0026] A neodymium-iron-boron magnetic material, comprising the following components by weight: 29 parts of praseodymium-neodymium alloy, 3 parts of dysprosium-iron alloy, 3 parts of boron-iron alloy, 0.6 part of niobium-iron alloy, 5 parts of yttrium-iron alloy, 1.0 part of nano silicon dioxide, gallium 0.1 part, 0.5 part of aluminum oxide, 1 part of antioxidant, and the balance is iron. The antioxidant is a mixture of antioxidant 1010 and antioxidant 1076, wherein the weight ratio of antioxidant 1010 to antioxidant 1076 is 1:1, and the particle size of silicon dioxide is 45nm.

[0027] A method for preparing an NdFeB magnetic material, comprising the following steps:

[0028] Step 1 batching: Weigh the raw materials according to the weight of each component in the NdFeB magnetic material, and mix the components together, after the mixing is completed;

[0029] Step 2 Melting the alloy: put the raw materials prepared in step 1 into the intermediate frequency vacuum melting f...

Embodiment 2

[0037] A neodymium-iron-boron magnetic material, comprising the following components by weight: 31 parts of praseodymium-neodymium alloy, 5 parts of dysprosium-iron alloy, 5 parts of boron-iron alloy, 0.7 part of niobium-iron alloy, 6 parts of yttrium-iron alloy, 2 parts of nano silicon dioxide, gallium 0.2 parts, 0.8 parts of aluminum oxide, 1.5 parts of antioxidant, and the balance is iron. The antioxidant is a mixture of antioxidant 1010 and antioxidant 1076, wherein the weight ratio of antioxidant 1010 to antioxidant 1076 is 1:2, and the particle size of silicon dioxide is 60nm.

[0038] A method for preparing an NdFeB magnetic material, comprising the following steps:

[0039] Step 1 batching: Weigh the raw materials according to the weight of each component in the NdFeB magnetic material, and mix the components together, after the mixing is completed;

[0040] Step 2 Melting the alloy: put the raw materials prepared in step 1 into the intermediate frequency vacuum melti...

Embodiment 3

[0048]A neodymium-iron-boron magnetic material, comprising the following components by weight: 33 parts of praseodymium-neodymium alloy, 6 parts of dysprosium-iron alloy, 7 parts of boron-iron alloy, 0.8 part of niobium-iron alloy, 8 parts of yttrium-iron alloy, 2.5 parts of nano silicon dioxide, gallium 0.3 parts, 1 part of alumina, 2 parts of antioxidant, and the balance is iron. The antioxidant is a mixture of antioxidant 1010 and antioxidant 1076, wherein the weight ratio of antioxidant 1010 to antioxidant 1076 is 1:3, and the particle size of silicon dioxide is 80nm.

[0049] A method for preparing an NdFeB magnetic material, comprising the following steps:

[0050] Step 1 batching: Weigh the raw materials according to the weight of each component in the NdFeB magnetic material, and mix the components together, after the mixing is completed;

[0051] Step 2 Melting the alloy: put the raw materials prepared in step 1 into the intermediate frequency vacuum melting furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com