La-Zn co-doping permanent magnetic strontium ferrite material powder and preparation method thereof

A strontium ferrite and co-doping technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of difficult industrial production of nano-powder, unprovided magnetic properties of material powder, and unfavorable industrial production. , to achieve the effect of excellent permanent magnet performance, scientific scheme and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

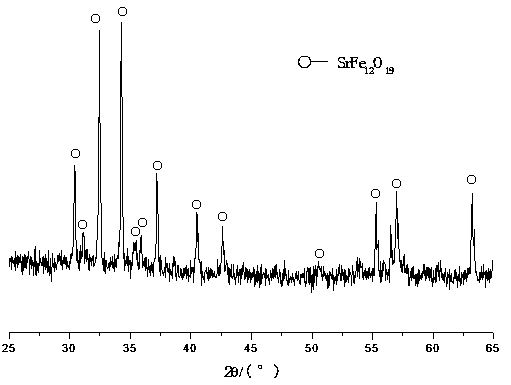

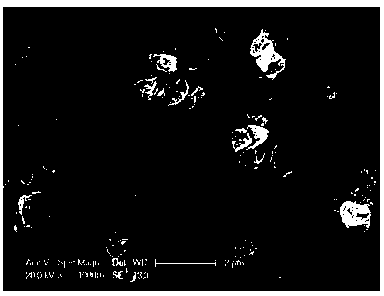

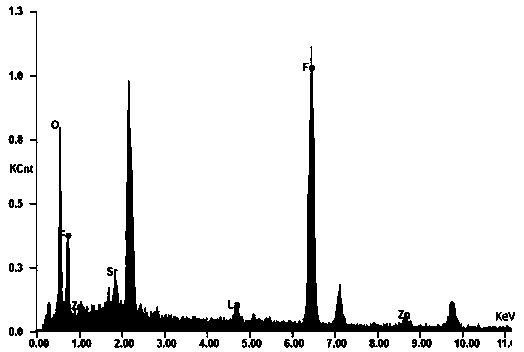

[0021] A La-Zn co-doped permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and strontium carbonate are used as raw materials, lanthanum oxide and zinc oxide are used as dopants, and the raw materials and the dopants are made of SrCO 3 : Fe 2 o 3 :La 2 o 3 : The molar ratio of ZnO is (0.81~0.9) : (5.94~5.98) : (0.05~0.09) : (0.06~0.12) to form a mixture, and 0.1~0.2wt% of the polyethylene glycol and the The water of 90 ~ 95wt% of the mixture is prepared into a slurry; then according to the mass ratio of the steel ball and the mixture (7.5 ~ 8.0): 1, the slurry is wet-milled in a steel ball mill, and wet-milled to The particle size is 0.6~0.9μm; then the ball-milled slurry is placed in a rotary kiln, and the temperature is raised to 1000~1050°C at a heating rate of 2~5°C / min, kept for 120~240 minutes, and cooled with the kiln to obtain La- Zn co-doped permanent magnet strontium ferrite powder.

[0022] The La-Zn co-doped permanent magnet...

Embodiment 2

[0024] A La-Zn co-doped permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and strontium carbonate are used as raw materials, lanthanum oxide and zinc oxide are used as dopants, and the raw materials and the dopants are made of SrCO 3 : Fe 2 o 3 :La 2 o 3 : The molar ratio of ZnO is (0.74~0.81) : (5.91~5.94) : (0.09~0.13) : (0.12~0.18) to form a mixture, plus 0.2~0.3wt% sorbitol and the Mix 95~100wt% of water to make a slurry; then wet grind the slurry in a steel ball mill tank according to the mass ratio of steel balls and mixture (8.0~8.5): 1, and wet grind to particle size 0.6~0.9μm; then put the ball-milled slurry into a rotary kiln, raise the temperature to 1050~1100℃ at a heating rate of 5~10℃ / min, keep it for 120~240 minutes, and cool down with the kiln to get La-Zn Co-doped permanent magnet strontium ferrite powder.

[0025] The La-Zn co-doped permanent magnet strontium ferrite powder prepared in this example is tested: the coe...

Embodiment 3

[0027] A La-Zn co-doped permanent magnet strontium ferrite powder and a preparation method thereof. Iron scale and strontium carbonate are used as raw materials, lanthanum oxide and zinc oxide are used as dopants, and the raw materials and the dopants are made of SrCO 3 : Fe 2 o 3 :La 2 o 3: The molar ratio of ZnO is (0.67 ~ 0.74): (5.88 ~ 5.91) : (0.13 ~ 0.17): (0.18 ~ 0.24) is made into a mixture, plus 0.3 ~ 0.4wt% calcium gluconate and the The water of 100 ~ 105wt% of the mixture is used to prepare the slurry; then according to the mass ratio of the steel ball and the mixture (8.5 ~ 9): 1, the slurry is wet-milled in a steel ball mill, and wet-milled to The particle size is 0.6~0.9μm; then put the ball-milled slurry into a rotary kiln, raise the temperature to 1100~1150℃ at a heating rate of 10~15℃ / min, keep it warm for 120~240 minutes, and cool down with the kiln to get La- Zn co-doped permanent magnet strontium ferrite powder.

[0028] The La-Zn co-doped permanent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com